Wood plastic decorative teak, plastic composite wood pipe 50*25mm

- $2.16 / 300 - 999 meters

$2.05 / 1000 - 2999 meters

$1.94 / 3000 - 4999 meters

$1.82 / >=5000 meters - 300 meters

- Ningbo Vocana Green Building Technology Co., Ltd.

- Zhejiang, China

- Ms feng xue

PRODUCT DETAIL

| type: | PVC-wood plastic composite material | After-sales service: | Online technical support, other |

| Project solution capabilities: | Graphic design, 3D model design, overall project solutions, cross-category integration | port: | Ningbo, Zhejiang/Zhoushan, Zhejiang/Shanghai |

| payment terms: | Letter of credit, wire transfer | Package: | Carton boards, plywood, waterproof clothing, pallets, etc. no wood |

| Packaging details: | Standard carton or woven bag packaging, no pallet. Customized packaging such as pallets, heat shrink, etc. can be provided if required. | Serve: | Customized ODM OEM |

| color: | Teak, walnut, IPE and other 7 colors | Warranty: | More than 5 years |

| Dimensions and outlet length: | 40*30/50*25/50*50/30*20/100*50 etc. | design style: | contemporary |

| Package preview: | FOB: | Ningbo, Zhejiang/Zhoushan, Zhejiang/Shanghai | |

| application: | Gardens, parks, courtyards, balconies, beach roads, swimming pool surrounds, etc., shopping malls | brand: | wokana |

| Place of origin: | Zhejiang, China | design: | touch |

| expiration of pay: | 30% T/T in advance, the balance 70% is paid before shipment | model: | VGS5025 |

Product parameters

applicationS

Residential Applications Commercial Applications Health/Elderly Care Facilities Educational Institutions Hospitality Industry Fit-out Retail and Shopping Centers

benefit

Lightweight, durable, fire-resistant and waterproof. Natural wood look and feel. Adds warmth and style. Enhances beauty. Multiple colors and finishes. Resistant to fungus, termites and mold. Eco-friendly product. Sound and thermal insulation. Quick and easy installation.

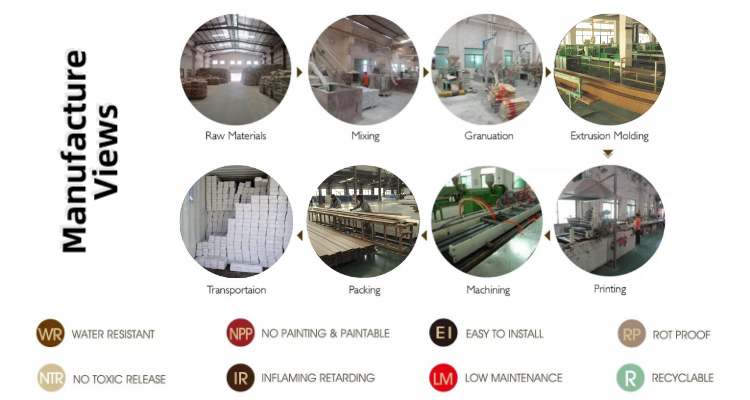

Manufacturing Technology

About Wokana

Wokana Green Building Technology has been involved in the wood-plastic composite industry since 2000, and its production base focuses on product research and development, production and supporting services. The product series includes composite flooring, wall panels, fences, railings, corridors, etc., which are exported to more than 90 countries and regions around the world.

workshop

In order to ensure the continuous production of high quality standards and the development of new products, VOCANA's granulation, extrusion and post-processing workshops all use customized advanced production equipment and implement professional production processes.

Production and processing

From material selection to finished product, products are screened and recorded in multiple processes, and are packaged after dust-free treatment. VOCANA has a professional loading and transportation team to ensure the smooth delivery of each batch of goods.

QC

VOCANA has complete and strict testing methods and processes. Every member of the quality control team has been carefully selected and has more than 10 years of work experience.

From raw materials to finished product shipment, the VOCANA quality control team does not miss any detail! Good quality is not only reflected in the appearance, but also in every aspect of the product. This is what the VOCANA quality control team always adheres to.

Design and customization

...-Project scene design-...

Want to know how VOCANA products work?

Wondering which colors are the most satisfying?

Want to get accurate installation design drawings?

VOCANA's professional design department meets all your requirements.

Wide range of applications

...- Apartments, hotels, villas, balconies... 600+ real cases around the world -...

VIEW MORE

YOU MAY LIKE