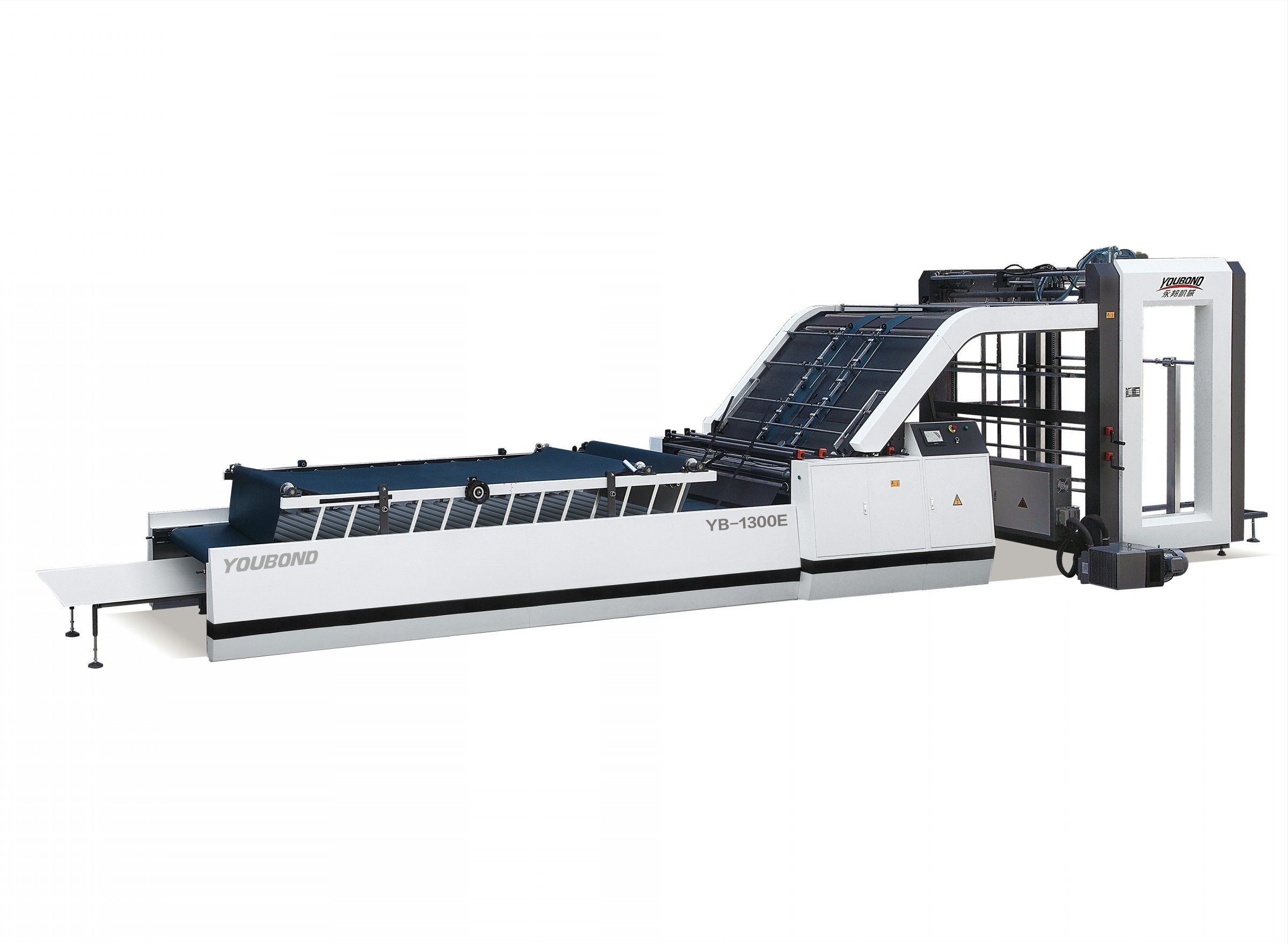

Youbond 1300E 1450E 1650E Automatic Carton Laminator

- $34000.00 /set

- 1 set

- Wenzhou Youbond Machinery Co., Ltd.

- Zhejiang, China

- Ms Grace Mao

| Core components: | PLC, gearbox, gear | Core component warranty: | 1 year |

| Main selling points: | easy to operate | Materials used for packaging: | metal, paper, plastic |

| speed: | 6000 sheets/hour | Driver type: | electrical |

| Supply capacity: | 20 sets per month | Maximum number of sheets: | 1300*1250/1450*1250/1650*1450mm |

| After-sales service provided: | Engineers available to repair machinery overseas | Mechanical test report: | if |

| Automatic level: | automatic | payment terms: | L/C, T/T |

| Applicable industries: | manufacturing plant | Voltage: | 380V/50Hz |

| application: | Mechanical Hardware, Lamination | 1450E Dimensions: | 11.5*2.2*2.4m |

| 1650E Dimensions: | 11.5*2.4*2.4m | Showroom location: | egypt, india |

| Warranty: | 1 year | Origin: | Zhejiang, China |

| Packaging Details: | There are no hard and fast rules for packaging | brand: | Eubond |

| port: | Ningbo Port | Paper thickness: | 150-600g |

| Min table: | 400x400 mm | type of packaging: | carton |

| Health status: | new | weight: | 5000 kg |

| Video outbound inspection: | if | feature: | Corrugated Laminating Machine |

| 1300E Dimensions: | 11.5*2*2.4m | type: | Automatic corrugated laminating machine, laminating machine |

automatic fluteLaminator (servo type)

feature:

1. Servo motor controls film

2. Front gauge and side gauge are used for plate alignment

3. Imported electrical components, stable operation

Technical parameters of YB-1300-1450-1650E corrugated laminating machine

| Model | YB-1300E | YB-1450E | YB-1650E |

| Maximum sheet | 1300×1250 mm | 1450×1250 mm | 1650×1450 mm |

| Minimum plate | 400×400mm | 400×400 mm | 400*400mm |

| Top paper thickness | 150-500g | 150-500g | 150-500g |

| Bottom thickness |

A, B, C, E, F flute, four-layer corrugated paper (AA, AB, BB), gray board paper |

||

| Maximum speed | 7000 sheets/hour | 7000 sheets/hour | 7000 sheets/hour |

| Fitting accuracy | ±1mm | ±1mm | ±1 mm |

| machine weight | 5000 kg | 5500 kg | 6000 kg |

| Measurement | 11.5×2×2.4M | 11.5×2.2×2.4M | 11.5×2.4×2.4M |

| machine power | 10kW/380V | 11kW/380V | 12kW/380V |

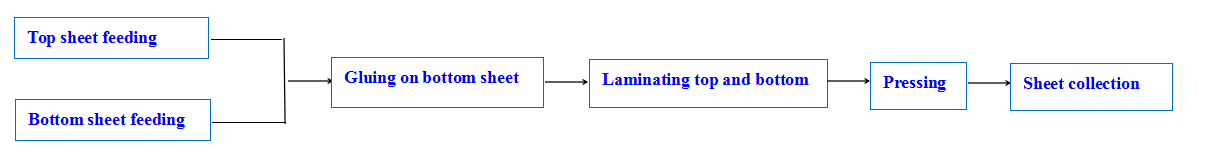

Production Process:

1. Top feeder part

4 paper suction cups and 4 paper feeding suction cups ensure stable and fast paper feeding. The nozzle angle is adjustable.

2. Bottom feed section

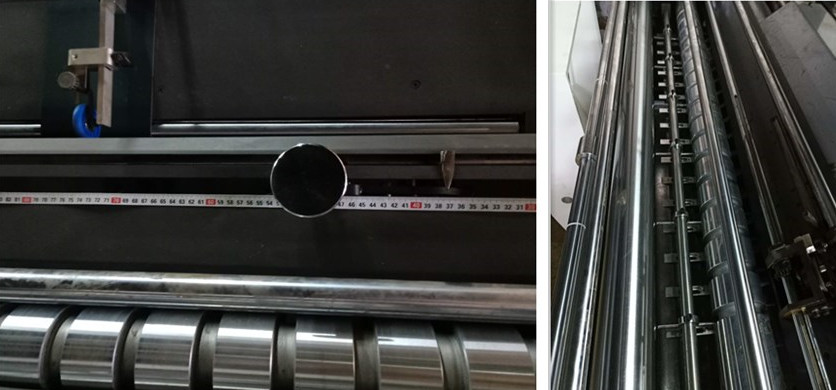

3. Pressure regulation part

Single side pressure adjustment to ensure the same pressure on both sides, with dial indicator display. The pressure for different negatives can be easily changed.

Lamination pressure glue volume adjustment

4. Plate positioning part

The top plate and bottom plate are aligned with the front and side gauges to make the front and side positioning accurate, and the position of the front plate is adjustable.

side gauge front gauge

5. Electrical components

Adopt Schneider, Siemens and other imported components, PLC tracking technology, automatic fault detection

6. Tablet pressing part

Press floating design, no need to adjust the pressure, heightened design smooth thick corrugated cardboard