ethanol plants

- $150000.00 /set

- 1 set

- Shandong Jinta Machinery Group Co., Ltd.

- Shandong, China

- Mr Rucheng Liang

| Processing: | Fermentation equipment | payment terms: | L/C, T/T, Western Union |

| Video shipment inspection: | if | Machine capacity: | 1500-100000 tons per year |

| After-sales service provided: | Engineers available to service machinery overseas | After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Supply capacity: | 30 sets per year | Core component warranty: | 1 year |

| Mechanical test report: | if | Health status: | new |

| Dimensions (L*W*H): | upon request | brand: | golden pagoda |

| Origin: | Shandong China | port: | Qingdao, Tianjin |

| Warranty: | 12 months | Local service location: | Brazil, Argentina |

| Certification: | CE, ASME, ISO | Packaging Details: | Standard export packaging |

| Material: | copper and stainless steel | Main selling points: | competitive price |

| Marketing Type: | New Products 2020 | Processing type: | Alcohol |

| Voltage: | 380V | Core components: | pressure vessel |

| strength: | Suitable for all lines | weight: | by design |

| Showroom location: | Brazil | Package preview: | |

| Applicable industries: | Manufacturing plants, food and beverage plants, energy and mining |

Specification

Turnkey Complete Alcohol Equipment

Fuel ethanol equipment

Alcohol distillation equipment

Dehydration ethanol equipment

Alcohol equipment, differential pressure, fuel ethanol equipment, dehydration alcohol ethanol equipment, rectification tower

1. It is a turnkey complete set of equipment, simple equipment, less workers, small floor space and low cost.

2. It can produce 1000L-1000000L 96%-99.9% alcohol (ethanol) every day.

3. Corn, wheat, cassava, molasses, rice, potato, jujube, beetroot, sugar cane and other materials containing starch or sugar can be used.

4. We can do turnkey system or parts.

5. Renovate the old alcohol (ethanol) production line.

6. We can provide energy saving suggestions.

You can choose a single distillation tower to save money, or you can choose 5 distillation towers to get high-quality alcohol (ethanol).

company information

Our company is the largest manufacturer of complete equipment for ethanol, fuel ethanol and DDGS high-protein feed in China.

Our company can design and manufacture Class I, II and III pressure vessels.

Our company has the turnkey project capability of design, manufacture, installation and commissioning of 3000t-500000t alcohol complete sets of equipment.

Product Description

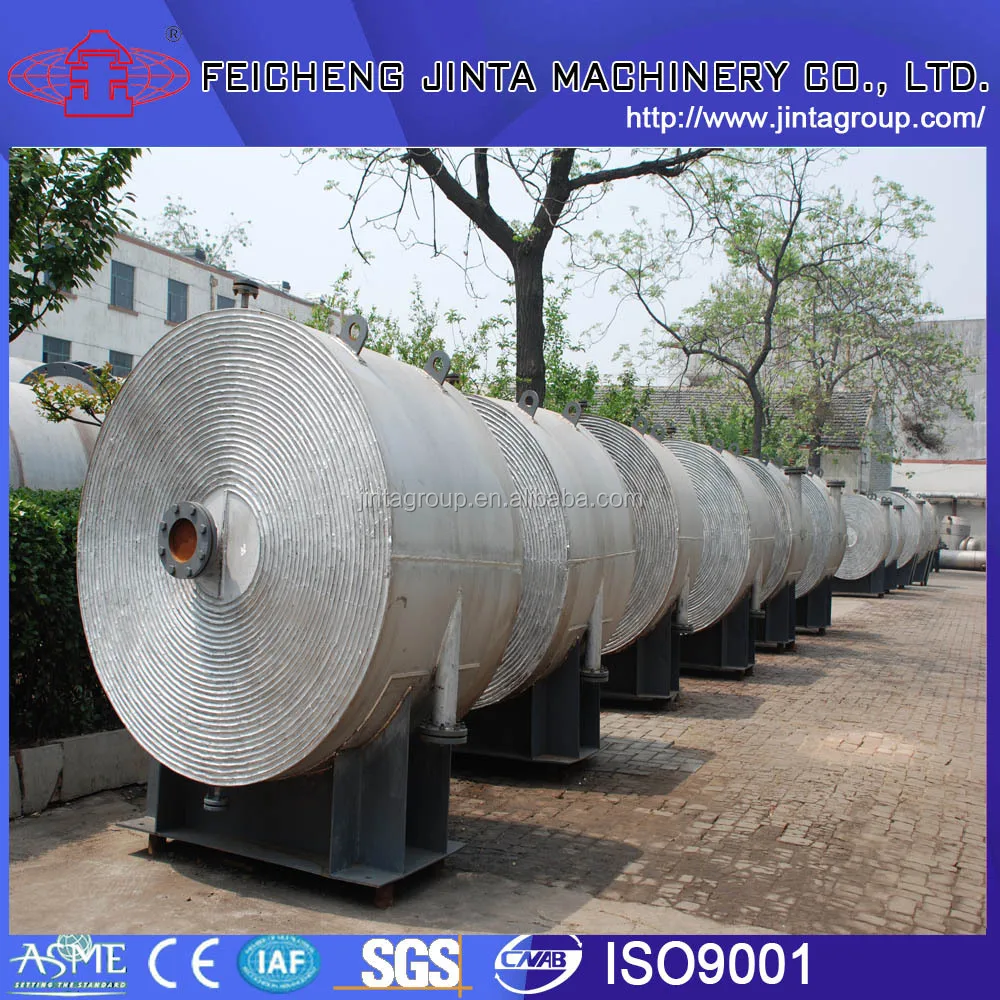

heat exchanger

heat exchangerIt is a high-efficiency heat exchange equipment used in alcohol, solvent, food fermentation, pharmaceutical, petrochemical, refrigeration, organic chemical, metallurgy and other industries. It is suitable for convective heat exchange from liquid to liquid, gas to gas, and gas to liquid.

Heat exchangers are divided into shell and tube heat exchangers and spiral plate heat exchangers. Tube heat exchangers include condensers, preheaters, reboilers, evaporators, and dryers. Spiral plate heat exchangers include non-detachable and detachable heat exchangers.

Heat exchanger materials are carbon steel and stainless steel.

PillarIt is a chemical equipment used to bring gas and liquid, gas and solid, liquid and liquid into close contact, and complete the process of heat transfer and mass transfer by catalyzing their interaction. Columns are used for distillation, absorption, extraction, etc.

According to different structures, the tower can be divided into plate tower and packed tower. The commonly used types are: bubble cap tower, packed tower, sieve plate tower, double flow tower, valve tower, rotating disk tower, etc.

pressure vesselIt is an airtight device that can withstand pressure and hold gas and liquid. According to the pressure bearing capacity, pressure vessels can be divided into low-pressure vessels, medium-pressure vessels and high-pressure vessels; Uses, pressure vessels can be divided into reaction vessels, heat exchange vessels, separation vessels, storage vessels. Our company can produce Class I, Class II and Class III stainless steel pressure vessels.

new process information

Five-tower three-effect distillation process

Our company designs and manufactures the latest five-tower three-effect distillation equipment. This new process is promoted on the basis of the traditional five-tower differential pressure tower, and is mainly used for the production of ultra-fine alcohol.

The key to this process is the heating method. The steam directly heats one tower and transfers the heat to the other four towers to achieve three-effect thermal coupling and energy saving.

In terms of electricity efficiency, it can save electricity by 50%, avoid the maintenance of the circulation pump, and prolong the service life of the reboiler.

Superfine Alcohol Energy Consumption and Quality Index Table

|

No. |

thing |

unit |

Traditional crafts |

New Technology |

|

1 |

steam consumption |

ton/ton |

3.0 |

2.3 |

|

2 |

Chroma |

No. |

9.5 |

8 |

|

3 |

Alcohol |

%(vol/vol) |

95.5 |

96.5 |

|

4 |

Sulfuric acid test |

No. |

70 |

9 |

|

5 |

Aldehydes (as acetaldehyde) |

mg/L |

28 |

2 |

|

6 |

Methanol |

mg/L |

18 |

3 |

|

7 |

n-propanol |

mg/L |

15 |

2 |

|

8 |

Isobutanol + Isoamyl Alcohol |

g/l |

27.5 |

2 |

|

9 |

acid (acetic acid) |

mg/L |

19 |

9 |

|

10 |

Esters (as ethyl acetate) |

mg/L |

twenty two |

16 |

|

11 |

Non-volatile matter |

mg/L |

twenty three |

12 |

|

12 |

heavy metal |

mg/L |

0.65 |

0.4 |

|

13 |

Cyanide (as HCN) |

mg/L |

3.7 |

2 |

Double Syrup Tower Three-Effect Distillation Process

This process is suitable for the production of general-grade alcohol and fuel ethanol, and has obtained a Chinese national patent. It is the only process in the world that successfully applies the three-effect double saccharification tower to produce general-grade alcohol.

The process consists of a saccharification tower, a rectification tower and a composite tower. The composite tower doubles as a saccharification tower and a rectification tower.

The key to this process lies in the heating method: steam directly heats one tower and transfers the heat to the other two towers to achieve three-effect thermal coupling and energy-saving effects.

The advantage of this process is energy saving; it saves more than 40% steam.

General grade alcohol energy consumption and quality index table

|

No. |

thing |

unit |

Traditional crafts |

New Technology |

|

1 |

energy used |

kWh/ton |

15 |

20 |

|

2 |

steam consumption |

ton/ton |

2.3 |

1.4 |

|

3 |

Water Consumption |

ton/ton |

7 |

5 |

|

4 |

Chroma |

No. |

9.5 |

8 |

|

5 |

Alcohol |

%(vol/vol) |

95.5 |

95.5 |

|

6 |

Sulfuric acid test |

No. |

70 |

55 |

|

7 |

Aldehydes (as acetaldehyde) |

mg/L |

28 |

25 |

|

8 |

Methanol |

mg/L |

100 |

55 |

|

9 |

n-propanol |

mg/L |

75 |

35 |

|

10 |

Isobutanol + Isoamyl Alcohol |

mg/L |

27.5 |

26 |

|

11 |

acid (acetic acid) |

mg/L |

19 |

18 |

|

12 |

Esters (as ethyl acetate) |

mg/L |

twenty two |

20 |

|

13 |

Non-volatile matter |

mg/L |

twenty three |

twenty one |

|

14 |

) heavy metal |

mg/L |

0.65 |

0.5 |

|

15 |

Cyanide (as HCN) |

mg/L |

3.7 |

3 |

our service

production capacity

1). Our company was established in the 1950s and designed and manufactured the first stainless steel distillation tower in China.

2) Our company can produce 6 complete sets of equipment a month (including crushing section, liquefaction and saccharification section, fermentation section, distillation section, DDGS section).

3). There are 16 production workshops, including 3 machinery manufacturing workshops, 5 processing workshops, and 8 assembly and welding workshops.

4). We have advanced mechanical processing equipment and product testing equipment.

Designing ability

1). Have D1, D2 special equipment design license; A2 special equipment manufacturing license; special equipment GC design license.

2). Our company has obtained more than 20 patent certificates in the fields of distillation and DDGS.

3). Our company has ASME certification, ISO 9001 quality system certification, ISO 14001 environmental management system certification and GB/T28001 occupational health and safety management system certification.

International Exchange and Cooperation

Jinta is the largest manufacturer of alcohol, fuel ethanol and DDGS equipment mechanical design in China. In the past 3 years, our company's alcohol equipment has maintained a market share of more than 60% in China, and its products have been exported to more than 30 countries such as Australia, Argentina, Brazil, and Russia. We can develop different schemes and annual output according to customers' raw materials and have advanced process technology, especially in terms of energy consumption.

After-sales service

1). Our company can provide perfect product after-sales service, and can guarantee the implementation, maintenance and debugging of the project.

2). We can arrive at the project site after receiving user notification.

Packaging and Shipping

contact us

Any questions, please feel free to contact us!