npk fertilizer manufacturing machinery factory

- $50000.00 / 1 - 1 sets

$10000.00 / >=2 sets - 1 set

- Anyang Hongmeng Machinery Engineering Co., Ltd.

- Henan, China

- Mr King Wang

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Output (kg/hour): | 8000 |

| type: | Press Granulator | Mechanical test report: | if |

| Video external inspection: | if | Warranty: | 12 months, 1 year |

| place of origin; place of origin: | Henan, China | product name: | Fertilizer production equipment |

| Core components: | PLC, motor | Type of machine: | Granulator |

| Supply capacity: | 100 sets per year | Function: | Production of NPK fertilizer granules |

| Applicable industries: | Manufacturing Plants, Farms, Energy & Mining, Fertilizer Plants | Health status: | new |

| capacity: | 1-16 tons/hour | application: | Fertilizer Granulator |

| Dimensions (L*W*H): | custom made | port: | Tianjin, Qingdao, Shanghai |

| Product Category: | fertilizer | brand: | Xin Sanguo |

| Raw materials: | fertilizer powder | Power (kW): | 100 |

| Weight (kg): | 10000 | Voltage: | 380V or customized |

| Main selling point: | easy to operate | Core Components Warranty: | 1 year |

| color: | green or customized | usage: | Make Fertilizer Granules |

| Key words: | Granulator Mechanical Fertilizer | Showroom location: | not any |

| Packaging Details: | NPK compound fertilizer granulation production line packaging specifications can be customized according to requirements | Marketing Type: | Hot Products of 2019 |

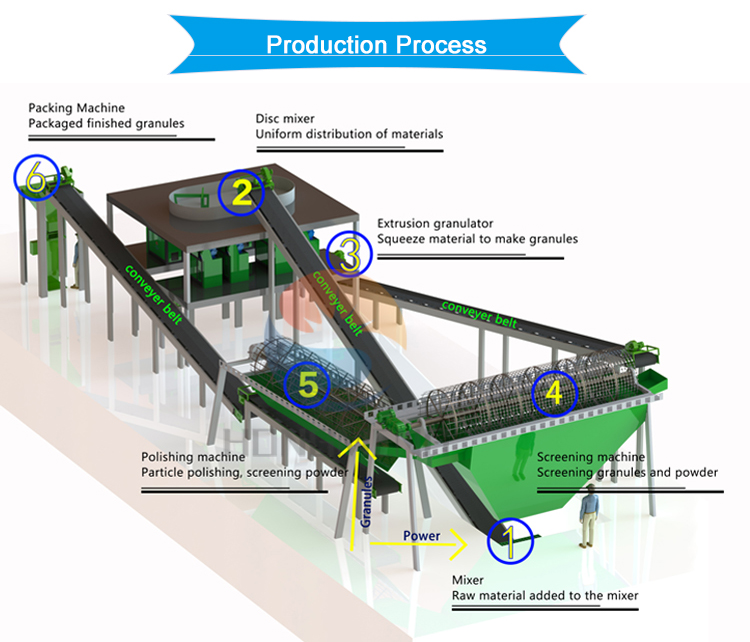

Earthworm calcium ammonium nitrate compound fertilizer production line

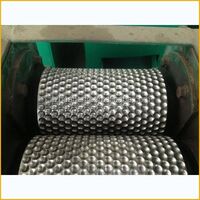

Anyang Hongmeng Mechanical Engineering Co., Ltd.Specializing in the production of twin-roll extrusion granulators, with 15 years of manufacturing experience. The equipment is suitable for granules such as ammonium bicarbonate, ammonium chloride, ammonium sulfate, ammonium nitrate, monoammonium phosphate, etc. The ball formation rate can reach 85%, using a drying-free process, granulating at room temperature, and forming at one time, less investment, quick results and good economic benefits.

Specifications of roller extrusion granulator

|

type |

DZJ-Ⅰ1.0 |

DZJ-Ⅰ2.0 |

DZJ-Ⅰ3.0 |

DZJ-Ⅰ4.0 |

DZJ-Ⅱ1.0 |

DZJ-Ⅱ2.0 |

|

productivity (tons/hour) |

1~1.5 |

1.5~2.5 |

2~3 |

3~4 |

1~2 |

1.5~2.5 |

|

Power(KW) |

15 |

18.5 |

twenty two |

30 |

15 |

18.5 |

|

Roller size (mm) |

Φ150x220 |

Φ150X300 |

Φ186X300 |

Φ300X300 |

Φ150X220 |

Φ150X300 |

|

Feed particle size (mm) |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

≤0.5 |

|

Product specification(mm) |

Φ2.5~Φ10 |

Φ2.5~Φ10 |

Φ2.5~Φ20 |

Φ2.5~Φ30 |

Φ2.5~Φ10 |

Φ2.5~Φ20 |

|

Reducer model |

ZQH350 |

ZQH400 |

ZQH400 |

ZQH500 |

invested |

invested |

|

Material moisture (%) |

2%~5% |

2%~5% |

2%~5% |

2%~5% |

2%~5% |

2%~5% |

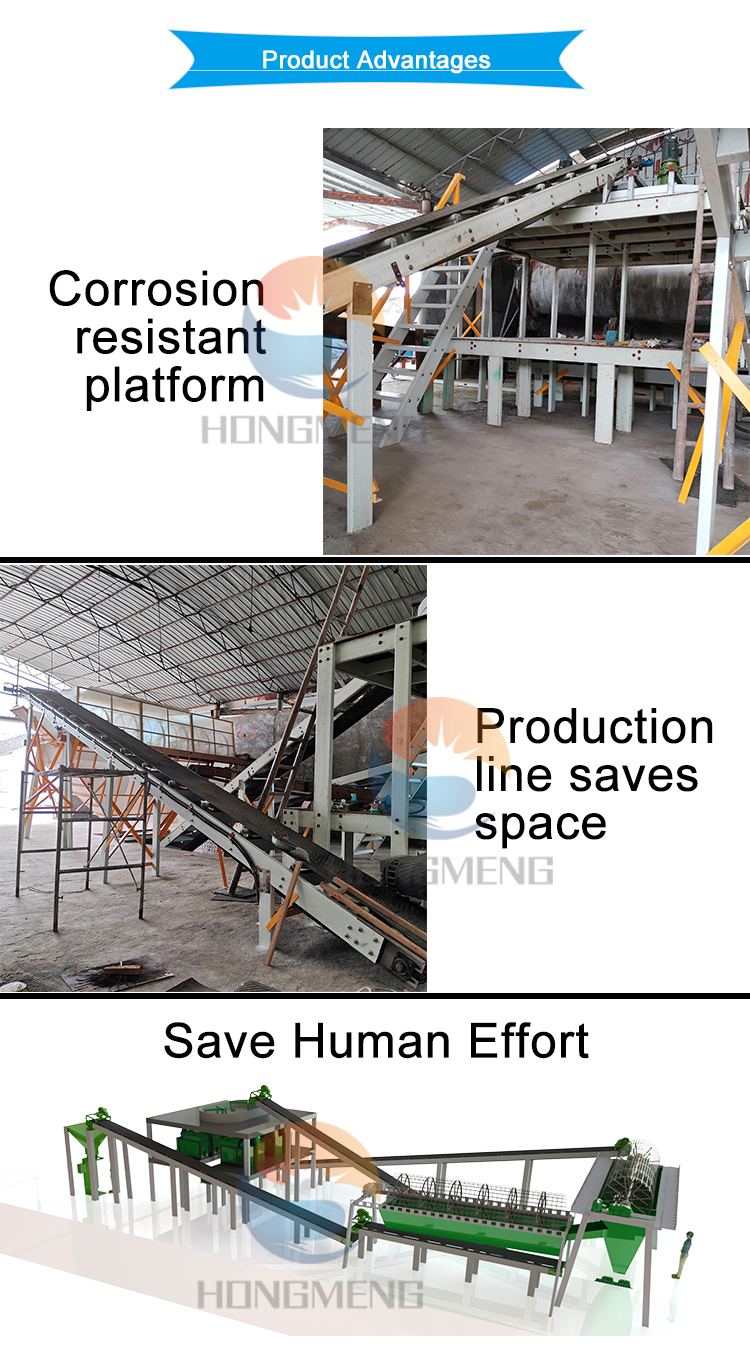

1. No drying process is required, granulation at room temperature, one-time molding, less investment, quick effect and good economic benefits.

2. Strong power, reliable operation, no three waste emissions, stable operation, convenient maintenance, reasonable process layout, advanced technology and low labor production cost.

3. The raw material has wide applicability and can be used for granulation of various raw materials such as compound fertilizer, medicinal fertilizer, organic and inorganic compound fertilizer, chemical industry, and feed.