small forges EN1677 Powder Coated Side Lifting Rings

- $2.12 /piece

- 1 piece

- Tianjin Yiyun Rigging Co., Ltd.

- Tianjin, China

- Mr Jerry Lei

PRODUCT DETAIL

| model: | YD083 | R: | 90 lbs, 100 lbs, 44 lbs, 40 lbs |

| Safety elements: | 4 times | Packaging Details: | carton |

| surface: | powder coating | place of origin; place of origin: | Tianjing, China |

| Lifting point inspection: | load test | WLL: | 0.7T |

| product name: | Universal rotating ring | Supply capacity: | 1000 pieces per month |

| Warranty: | 6 months | color: | Orange/OEM |

| payment terms: | Western Union, T/T, MoneyGram | grade: | 80 |

| port: | Newport | Material: | alloy steel |

| size: | M12 | Custom Support: | OEM |

| factory: | Tianjin Yiyun | Packaging Preview: |

detailed picture

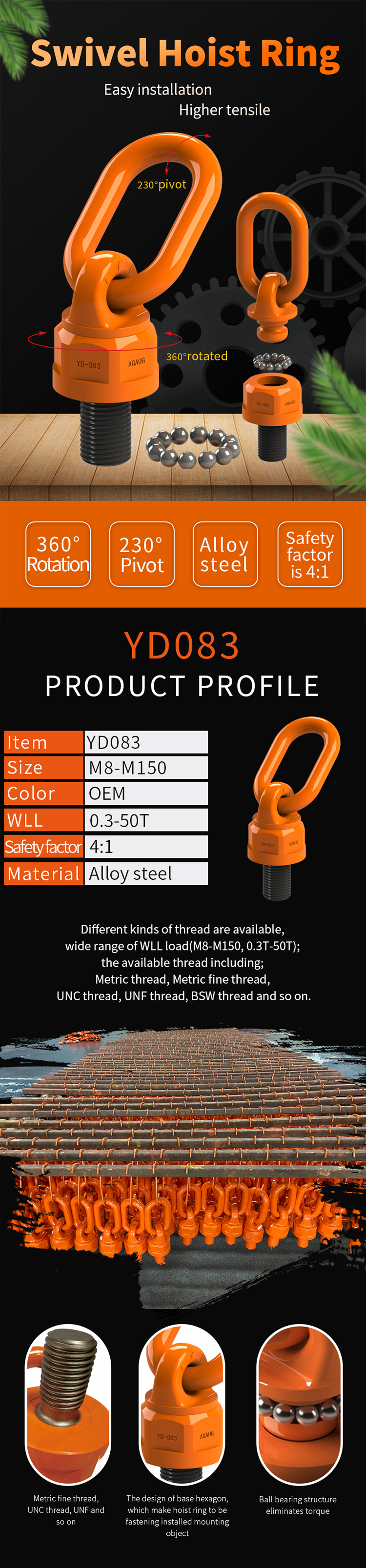

Product name: YD083 Universal rotating ring

The universal rotating lifting ring is forged with special alloy steel, and is treated with high-strength quenching and tempering. It has superior mechanical properties. The eyebolts are the eyebolts of the load pair. They are designed to be mounted from the center or side and can be pivoted or rotated. Some rings are attached directly to webbing, chains or shackles. Others have a hook end instead of the standard bail, eye or loop.

Load: 230° pivot, 360° swivel

Standard: EN1677-1:2000

Applications: Uncertain power, wind power, tooling and mould making and traditional lifting industries.

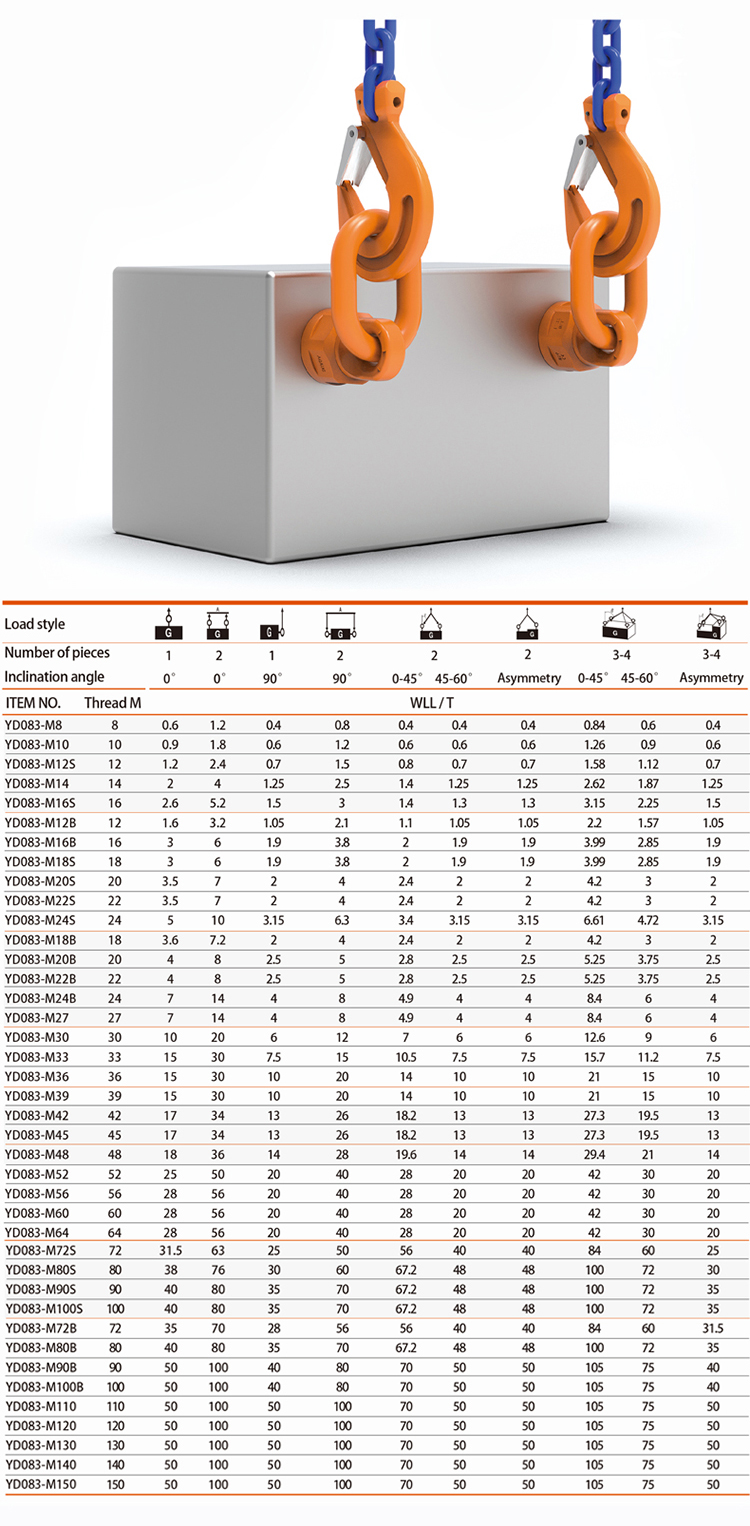

Purpose: Vertically hoisting the largest WLL

Assemble multiple swivel rings, the angle of the wire rope is less than 120°

Assembled with multiple swivel rings, WLL slightly lower or more

Assembled with multiple swivel rings, side pulls have the same WLL as vertical pulls.

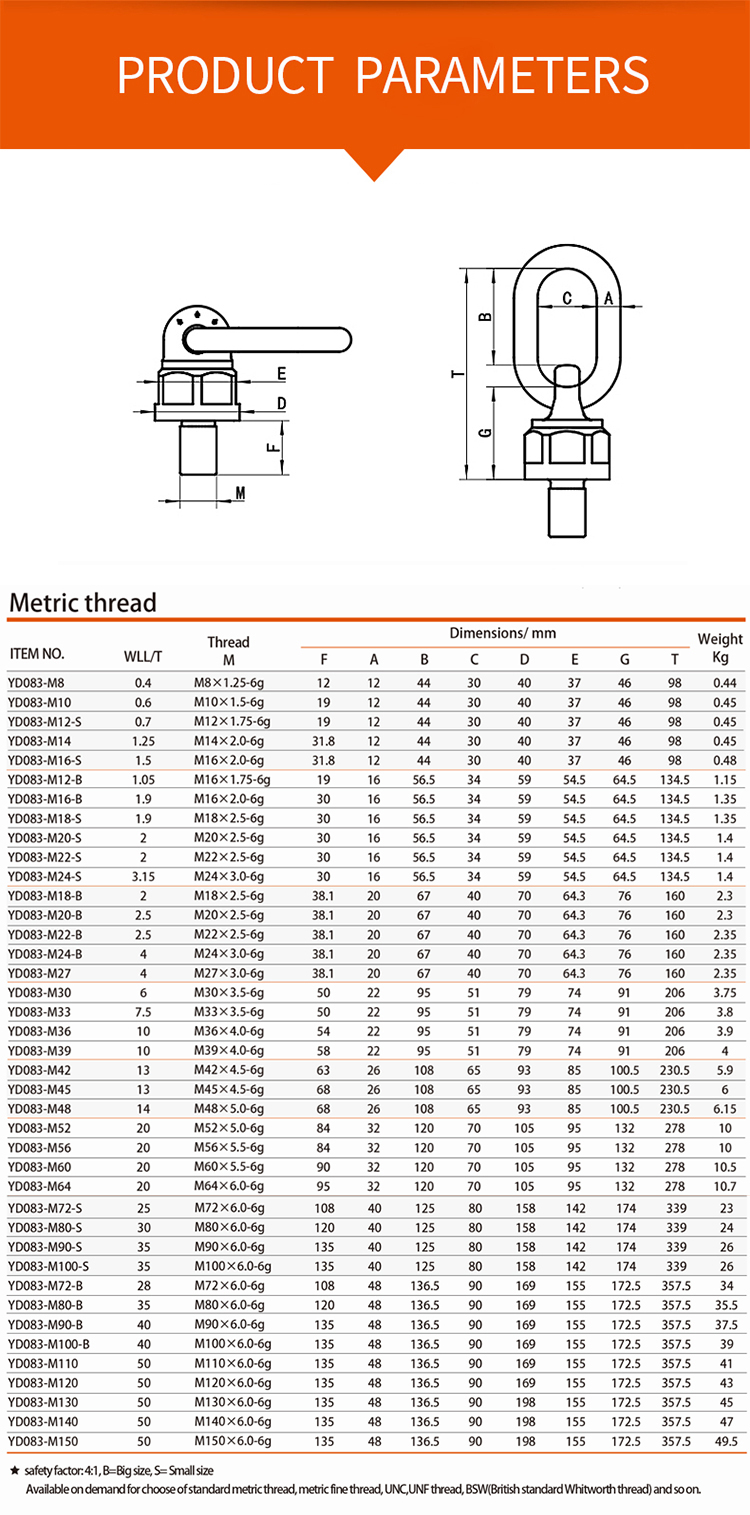

Metric thread: standard from M 8 to M 150; suitable for loads from 0,3 t to 40 t

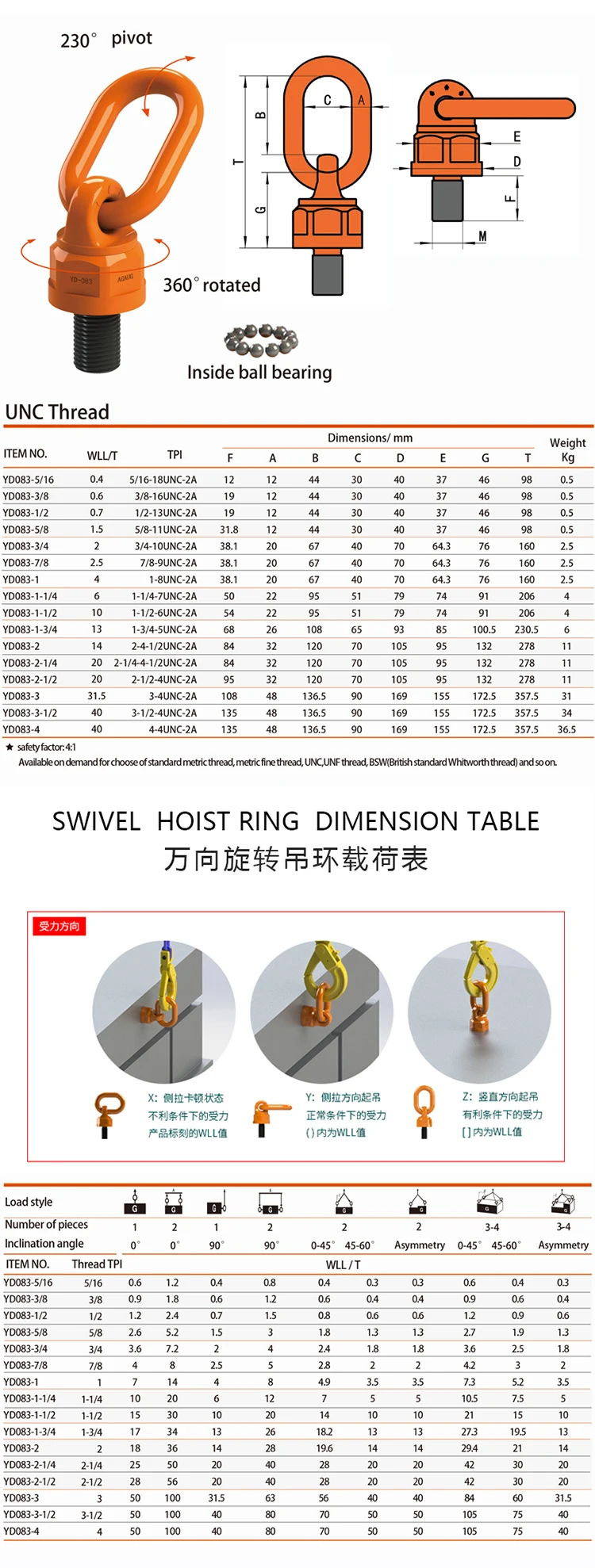

UNC Threads: Standard from UNC 5/16'' to UNC 4''; for loads from 661 lbs to 88,184 lbs

Safety factor: 4:1

Rotating under load, can be used for any type of lifting operation, two types of tightening

Standard: EN1677-1:2000

Applications: Uncertain power, wind power, tooling and mould making and traditional lifting industries.

Purpose: Vertically hoisting the largest WLL

Assemble multiple swivel rings, the angle of the wire rope is less than 120°

Assembled with multiple swivel rings, WLL slightly lower or more

Assembled with multiple swivel rings, side pulls have the same WLL as vertical pulls.

Metric thread: standard from M 8 to M 150; suitable for loads from 0,3 t to 40 t

UNC Threads: Standard from UNC 5/16'' to UNC 4''; for loads from 661 lbs to 88,184 lbs

Safety factor: 4:1

Rotating under load, can be used for any type of lifting operation, two types of tightening

Product Description

100% Magnaflux crack detection. Rated to 100% at 90° angle. Lifting rings Lifting rings are designed in forged alloy steel, which has been quenched and tempered. 360° rotation with 180° pivot function. Bolts are hexagon socket head cap screws with a metric thread gauge of grade 10.9 alloy.

Our advantage

Advantages of lifting rings1 The raw material is optimized to select high-quality alloy steel 42CrMo. Optimization of raw materials can significantly improve WLL 2 The improved WLL lifting ring is inherently stronger for linear use. 3 Safety factor and marking We offer certified lifting rings with WLL, thread size marking and a 4:1 safety factor as defined by the EN 1677-1 standard. 4 Anti-corrosion coating The anti-corrosion coating means that the unpainted part of the swivel lifter is resistant to salt spray 5 The more effective lifter is 100% compliant than traditional DIN 580 lifter bolts In keeping with its mission statement, it pays special attention to its lifter's appearance orange.

Manufacturing Technology

WLL series (M8-M150, 0.3-50T) can provide standard metric thread, metric fine thread, UNC, UNF thread, BSW (British Standard Whitworth thread), etc. on request.

Product packaging

exhibition

VIEW MORE

YOU MAY LIKE

Other Products

-

Rigging Bolts on Lifting Eyes Rotating Swinging Eyebolts 20 Ton M48 Side Rotating Load Rings Over Lifting Rings

Rigging Bolts on Lifting Eyes Rotating Swinging Eyebolts 20 Ton M48 Side Rotating Load Rings Over Lifting Rings -

ISO standard eye bolts, factory eye bolts, swivel eye bolts$18.00 - $20.00 / piece

ISO standard eye bolts, factory eye bolts, swivel eye bolts$18.00 - $20.00 / piece -

Type SHACKLES Individual Traceability Number G80 Bolts on lifting points 20T$18.00 / piece

Type SHACKLES Individual Traceability Number G80 Bolts on lifting points 20T$18.00 / piece -

Swivel lifting eye M12 for lifting material orange$4.00 / piece

Swivel lifting eye M12 for lifting material orange$4.00 / piece -

G80 Heavy Duty Eyebolts M36 8T with CE Certificate$4.00 / piece

G80 Heavy Duty Eyebolts M36 8T with CE Certificate$4.00 / piece