6000 kg/h stainless steel three stage emulsion pump 7.5 KW continuous mixer for liquid coating agrochemicals seed

- $2800.00 / 1 - 4 sets

$2700.00 / 5 - 9 sets

$2600.00 / >=10 sets - 1 set

- Anhui Bunkin Chemical Machinery Co., Ltd.

- Anhui, China

- Mr Jack Zhang

PRODUCT DETAIL

| Pre-sale Services: | Product/factory live via video call; | Port: | Shanghai( or other seaports); |

| Warranty of core components: | 1 Year; | Brand Name: | Bunkin; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Warranty: | 1 Year; |

| Motor: | Local/imported/explosion proof; | Packaging Detail: | Plywooden case; |

| Inlet pressure: | 0.3MPa; | Machinery Test Report: | Provided; |

| Power: | 4-75kw; | Package Preview: | ; |

| Marketing Type: | New Product 2021; | Showroom Location: | Italy,Viet Nam,Brazil,Pakistan,Russia,Uzbekistan; |

| Outlet pressure: | 0.3Mpa; | Condition: | New; |

| Type: | Emulsifier; | Key Selling Points: | High-accuracy; |

| Weight (KG): | 170; | Supply Ability: | 30 Sets per Quarter; |

| Video outgoing-inspection: | Provided; | Working head: | standard & Custom design; |

| Payment Terms: | Western Union,T/T,MoneyGram,paypal; | Use: | agri seed treatment; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Food Shop,Food & Beverage Shops; | Speed: | 1500/1800/3000/3600 rpm; |

| Inlet - outlet size: | DN 50 - DN 40 / customised; | Material Lift (water): | 10 meter high; |

| Dimension(L*W*H): | 800mm*350mm*390mm; | Place of Origin: | Anhui, China; |

| Optimized: | Control Panel/Speed Adjuster; | Production Capacity (kg/h): | 5000-6000; |

Products Description

Pipeline Three-Stage Emulsification Pump

The pipeline three-stage emulsification pump is a high-speed and high-efficiency emulsifier for continuous production or circulating processing of fine materials.The motor drives the rotor to run at high speed, and the particle size of the liquid-liquid and solid-liquid materials is narrowed through the action of mechanical external force, so that one phase is uniformly distributed into another or multiple phases to achieve refined homogeneity and dispersion emulsification effect, thereby forming a stable emulsion state.The single-stage pipeline high-shear emulsifier can be equipped with a feeding pump, which is suitable for medium and high viscosity materials.The equipment has low noise, stable operation, no dead ends, and the material is forced to pass through the function of dispersion and shearing. It has the function of short-distance & low-lift conveying.

Product Characteristics

1. Continuous dispersion and emulsification effect is good, cleaning CPI design.

2. The speed can reach 3000 rpm, and the speed can be adjusted through the energy-saving and environmentally-friendly frequency converter.

3. Design and manufacture of all stainless steel body, optional sanitary stainless steel motor cover.

4. The rotor and stator are manufactured by CNC machining center with one piece of forging material, with high precision and high linear speed.

5. Adopt double end face mechanical seal design, no leakage, safe and reliable, reducing maintenance cost.

6. The mechanical seal is designed to protect against water shortage, the jacket design allows flexible heating and cooling adjustments, and the machine can run for a long time.

7. Various connection methods such as flange, quick connection, SMS quick installation, etc. can be provided according to actual needs. Can be customized for special pressure and special temperature (high temperature resistance, low temperature resistance) environment.

Technical Parameters

Model | Power | Rotating Speed | Processing capacity | Lift | Inlet | Outlet | Dimensions (mm) | Weight (Kg) | ||||||||

BZ3-4 | 4Kw | 3000rpm | 2.5m3/h | 10m | DN40 | DN32 | 1000*300*350 | 125 | ||||||||

BZ3-7.5 | 7.5Kw | 3000rpm | 6m3/h | 10m | DN50 | DN40 | 1100*350*390 | 170 | ||||||||

BZ3-11 | 11Kw | 3000rpm | 11m3/h | 10m | DN65 | DN50 | 1200*400*390 | 225 | ||||||||

BZ3-15 | 15Kw | 3000rpm | 16m3/h | 10m | DN65 | DN50 | 1200*400*460 | 260 | ||||||||

BZ3-18.5 | 18.5Kw | 3000rpm | 20m3/h | 10m | DN80 | DN65 | 1200*400*460 | 295 | ||||||||

BZ3-22 | 22Kw | 3000rpm | 25m3/h | 10m | DN80 | DN65 | 1350*400*510 | 320 | ||||||||

BZ3-30 | 30Kw | 3000rpm | 32m3/h | 10m | DN100 | DN80 | 1500*450*550 | 380 | ||||||||

BZ3-37 | 37Kw | 3000rpm | 40m3/h | 10m | DN100 | DN80 | 1860*500*650 | 470 | ||||||||

BZ3-45 | 45Kw | 3000rpm | 50m3/h | 10m | DN125 | DN100 | 1970*600*770 | 560 | ||||||||

BZ3-75 | 75 | 3000rpm | 60m3/h | 10m | DN125 | DN100 | 2250*700*920 | 750 | ||||||||

* Special liquid contact materials and power supply, voltage can be customized | ||||||||||||||||

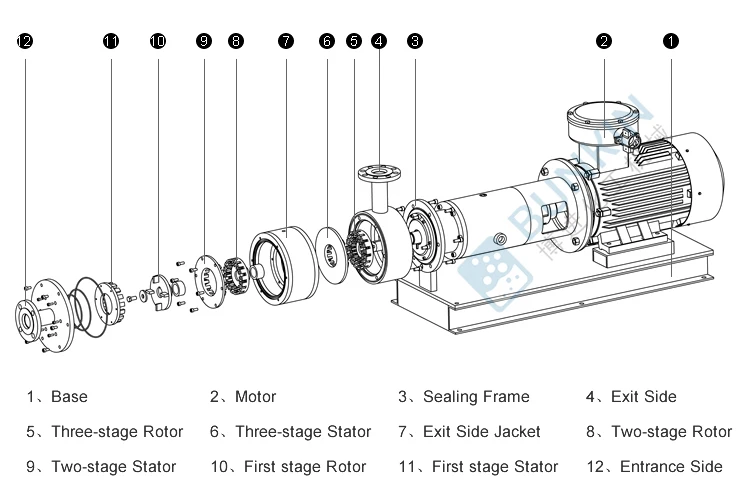

Components & Features

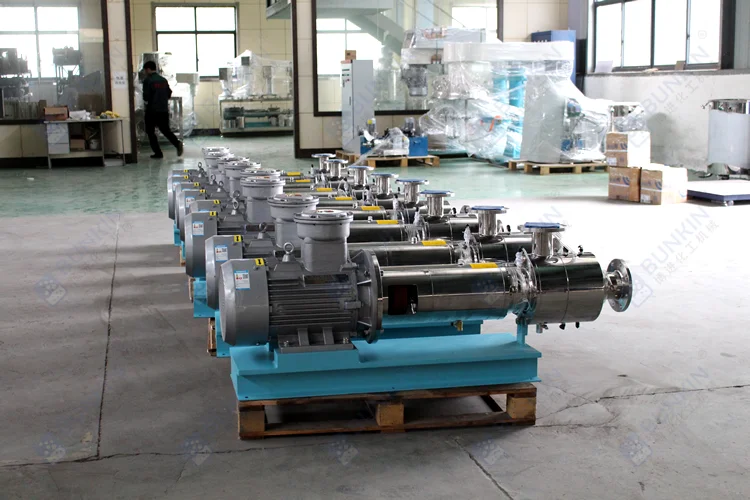

Products Display

Packaging & Shipping

FAQ

1.What kind of machines can you supply to customer?

We manufacture various kinds of wet milling chemical machines like basket mill, high shear mixer, horizontal bead mill, inline high shear emulsifying pump, three roll mill, multi-function kettles, etc. It is widely used for paints and coating,printing inks, adhesives, cosmetics, fertilizers, liquid detergent, flavors & fragrances and liquid agrochemical products.

2.What's the material of your machine?

The standard material of our machine is SUS304, according to the medium and requirements of customer material can be customized by SUS316 or rubber coating.

3.Why your machine similar with other supplier?

We are manufacturer and had been in this industry for more than 10 years. We design machines with advanced technology and built it as per customer requirement. We believe in service, performance and quality rather than appearance.

4. How to choose the model?

In order to select a machine according to you desire, kindly advise the mixing media, dimension of tank, type and other special technical data, then we will design and choose the suitable model for you.

5.What services do you offer?

We provide OEM service and also offer the specific product you need.

Contact Us

Over 20 Years, Bunkin mainly focused on chemical equipment's and machinery to provide fluids homogenizing, emulsifying, dispersing, homogenization, grinding, mixing, filling and related equipment's

We provide solutions, one step shop. Our services are design, manufacturing, sales, installation and after-sales services.

Email: [email protected] Website : http://bunkinchina.com

VIEW MORE

YOU MAY LIKE