Elastic Band Making Machine / Rubber Ring Producing Line with Technical Support

- $7000.00 /set

- 1 set

- Qingdao Shun Cheong Rubber Machinery Manufacturing Co., Ltd.

- Shandong, China

- Mr Jake Chen

| Payment Terms: | L/C,T/T; | Capacity: | 1800 kg/h; |

| HS code: | 84778000; | Supply Ability: | 20 Sets per Month; |

| Diameter of Screw: | 200 mm; | Applicable Industries: | Manufacturing Plant,Machinery Repair Shops,Retail; |

| Port: | Qingdao; | Warranty of core components: | 2 years; |

| Year: | Customized; | Screw L/D Ratio: | 1 : 4.4; |

| Service: | Customized; | Output (kg/h): | 1800 kg/h; |

| Showroom Location: | Egypt,Viet Nam,Brazil,Russia; | L:D: | 4.4 : 1; |

| Weight (KG): | 3800 KG; | Key Selling Points: | Long Service Life; |

| Power (kW): | 90; | Warranty: | 12 months; |

| Packaging Detail: | wooden packaging can be customized. key parts will be wrapped by shockproof packaging materials, and then packed in wooden cases.; | Place of Origin: | Shandong, China; |

| Brand Name: | SFC; | Video outgoing-inspection: | Provided; |

| Voltage: | 380V or as your requirement; | Type: | Rubber Product Making Machine; |

| Screw diameter (mm): | 200 mm; | Package Preview: | ; |

| Dimension(L*W*H): | different size; | Screw Speed (rpm): | 3 - 64 rpm; |

| Core Components: | Engine,Gearbox,Motor; | Marketing Type: | Hot Product 2019; |

| Machinery Test Report: | Provided; | After Warranty Service: | Field maintenance and repair service; |

| Condition: | New; |

Complete Rubber Band Production Line with Technical Support

Qingdao Shun Cheong Rubber Machinery Manufacturing Co.,Ltd. is located in the west coast of Qingdao city, it is a specialist manufacturer of rubber machinery. Our company commits to the developing and research for rubber machinery, active introduction of foreign designing and manufacturing technology.

The company carries out ISO9001:2008 Quality Management System, with advanced manufacturing equipment, rich technology and complete sales service system. The general manager Mr. Kenny Liu (Whatsapp : 0086-18253286958) warmly welcomes business friends from all walks of life to build business relationship to create bright achievement future.

Rubber Band Extrusion Production Line:

|

No. |

Item |

Quantity (Set) |

|

01 |

Rubber Bale Cutter |

1 |

|

02 |

Rubber Kneader Machine |

1 |

|

03 |

Rubber Mixing Mill |

1 |

|

04 |

Hot Feeding Rubber Extruding Machine |

1 |

|

05 |

Vulcanizing Tank |

1 |

|

06 |

Rubber Band Cutting Machine |

1 |

Application:

Hot feeding rubber extruder machine can be used for the shaping extrusion of various kinds of rubber products, rubber products, rubber wrap up for the out layer of the wire and electric cable and to do the rubber filter extrusion as well.

|

Parameter/Type |

XJ-65 |

XJ-120 |

XJ-150 |

XJ-200 |

|

Screw Diameter (mm) |

65 |

120 |

150 |

200 |

|

Length-diameter Ratio of Screw(L/D) |

4 |

4.6 |

4.43 |

4.35 |

|

Rotary Speed of Screw r/min |

5.2~52 |

5.6~55.6 |

20~26 |

22.4~67.2 |

|

Production Capacity (kg/h) |

50~80 |

100~450 |

700-1200 |

1500-2200 |

|

Stream Pressure (Mpa) |

0.2-0.3 |

0.2~0.4 |

0.6 |

0.6-0.8 |

|

Cooling Water Pressure (Mpa) |

0.2-0.3 |

0.2~0.4 |

0.2-0.3 |

0.2-0.3 |

|

Size (L×W×H)(mm) |

1750×550×1100 |

2427×750×1330 |

3411×814×1470 |

4564×1800×1750 |

Our main products includes:

Mixing Equipment: Rubber Kneader, Two Roll Mill, Rubber Sheeting Mill, Rubber Refining Mill, Rubber Crusher.

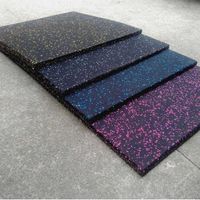

Curing Equipment: Pillar / Frame Type Plate Vulcanizing Press, Duplex Curing Press, Rubber Tiles Vulcanizing Press, Jaw Vulcanizing Press Machine, Large Plate Vulcanizing Machine, Automatic Plate Vulcanizing Molding Machine, etc.

Extruding Equipment: Hot Feed Extruder, Rubber Strainer, EPDM Rubber Extrusion& Vulcanizing Line.

Calender Equipment: Two Roll Calender, Three Roll Calender, Four Roll Calender, Inner Liner & Rubber Calender Line.

Waste Tires Recycling Equipment: Semi-automatic Waste Tires Recycling Line, Full- automatic Waste Tires Recycling Line, New Type Waste Tires Recycling Line. Fine Rubber Powder Pulverizer.

Other Equipment: Reclaimed Rubber Production Line, Batch-Off Cooler, Conveyor Belt Splicing Press, and so on.

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production manufacturers.

If you come to our factory, we can show the user around us.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao liuting airport. We will pick up you at the airport.

Other Products

-

Tire cutting machine for recycling used tires$4300.00 / unit

Tire cutting machine for recycling used tires$4300.00 / unit -

Waste tire recycling vulcanized rubber tile press$2800.00 - $3000.00 / set

Waste tire recycling vulcanized rubber tile press$2800.00 - $3000.00 / set -

Competitive price of vertical hydraulic single knife rubber baler$1700.00 - $2000.00 / set

Competitive price of vertical hydraulic single knife rubber baler$1700.00 - $2000.00 / set