1/4 Frozen French Fries Machine

- $120000.00 / 1 - 2 sets

$115000.00 / >=3 sets - 1 set

- Zhucheng Lijie Food Machinery Co., Ltd.

- Shandong, China

- Mr Dave wang

PRODUCT DETAIL

| Supply capacity: | 10 sets per month | Packaging Details: | wooden box |

| Core component warranty: | 1 year | capacity: | 50-2000kg/hour |

| Showroom location: | England America | Main selling points: | high productivity |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | shape: | potato chips french fries |

| Video shipment inspection: | if | weight: | 500 kg |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Origin: | Shandong China |

| Dimensions (L*W*H): | 25000*1500*1500 | Package preview: | |

| strength: | 30KW | Output product name: | potato chips |

| Mechanical function: | fried | port: | Qingdao |

| Mechanical test report: | if | Applicable industries: | Hotel, Manufacturing Plant, Food & Beverage Factory, Farm, Restaurant, Retail, Food Store, Printing Shop, Construction Works, Food & Beverage Store, Advertising Agency |

| heating method: | Electric/gas heating | Warranty: | 1 year |

| Material: | stainless steel 304 | Final product: | baked potato chips |

| Name: | french fries factory | raw material: | corn, vegetables |

| Voltage: | 380V | type: | french fries factory |

| brand: | Li Jie | Marketing Type: | 2019 Hot Products |

| Health status: | new | Application fields: | Vegetable processing factory, edible oil factory, fruit processing factory, snack food factory, frozen food factory, beverage factory |

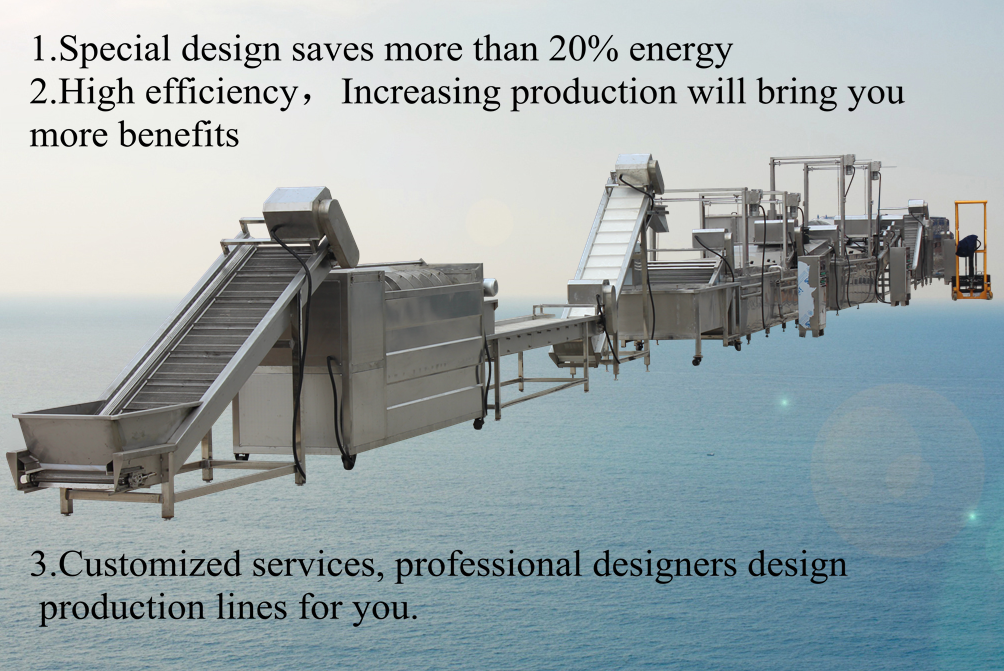

100-3000kg/h Fully automatic French fries frying line

French fries processing flow: Elevator—cleaning and peeling machine—picking line—cutting machine—elevator—rinsing machine—blanching line—drying and dehydrating line—continuous frying machine—vibrating screen ——air drying and deoiling machine——IQF machine——automatic packaging machine——finished product.

We can customize different potato chip production lines

Production capacity, provide different heating methods according to your requirements, and provide complete solutions and turnkey projects.

Production capacity, provide different heating methods according to your requirements, and provide complete solutions and turnkey projects.

The fully automatic potato chip processing plant (potato chip making machine/french fries machine) is an assembly line specially designed for making potato chips, and its production capacity

It is 100kg/h-3t/h. The whole production line includes multiple machines made of all stainless steel, and 3 to 5 people are required to work,

Compared with the semi-automatic line, the work efficiency is greatly improved.

It is 100kg/h-3t/h. The whole production line includes multiple machines made of all stainless steel, and 3 to 5 people are required to work,

Compared with the semi-automatic line, the work efficiency is greatly improved.

Specification

No. | equipment | strength | weight | size |

1 | Potato cleaning and peeling machine | 4.37kw/380v/50Hz | 630 kg | 3400*900*1400mm |

2 | potato slicer | 1.1kw/380v/50Hz | 120 kg | 950*800*950mm |

3 | cleaning | 2.2kw/380v/50hz | 500 kg | 2600*1000*1300mm |

4 | rinse machine | 6.6kw/380v/50Hz | 800 kg | 4000*1200*1300mm |

5 | Blanching machine | 120kw/380v/50Hz | 1400 kg | 5000*1200*1300mm |

6 | Air drying dehydrator | 0.75kw/380V/50HZ | 500 kg | 6000*1000*1150mm |

7 | Vibrating dehydrator | 0.5kw/380v/50Hz | 230 kg | 1800*1000*1300mm |

8 | Electric fryer | 180kw/380v/50Hz | 1500 kg | 5000*1100*2200mm |

9 | Vibration deoiler | 0.5kw/380v/50Hz | 230 kg | 1800*1000*1300mm |

10 | Air Drying Deoiler | 100kw/380/50hz | 5000 kg | 8500*3300*3000mm |

11 | Potato Chip Packaging Machine | 6kw/380v/50hz | 1200 kg | 3000*3000*2600mm |

detailed drawing

Feeding pre-washing hoist

(2) Features: SUS 304, easy to maintain, easy to clean, no rust.

(3) Technical parameters:

Size: 2500*600*1500mm

Power: 0.75KW/380v/50Hz mesh

Belt width: 600mm Frame: 50*50*2mm rectangular stainless steel square tube

Belt width: 600mm Frame: 50*50*2mm rectangular stainless steel square tube

Cleaning and Peeling Machine

(1) Use: Potatoes are washed and peeled continuously.

(2) Features: Two peeling machines are arranged one high and one low, and the screw discharger realizes continuous production.

Imported nylon brush roller, durable, stainless steel frame structure.

(3) Technical parameters:

Dimensions: 2300*760*1650mm, brush roller length: 2000 mm

Power: 3.75kw /220v/3 phase.

Brush rollers: 9 nylon brush rollers.

(4) Material disposal

Spiral teeth: made by bending stainless steel plate

Other materials: 304 stainless steel plate, welded and sheared.

Cutting Machine

(2) Features: American technology, the blade is strong and durable, and runs smoothly. Large capacity, good cutting effect.

(3) Technical parameters:

Dimensions: 1100*660*900mm

Power: 1.5kw /380v/ 50Hz

Cutting thickness: 2mm

Capacity: 2000kg/h

(4) Material disposal

Frame material: 304SUS

Blanching machine

(1) Use: blanch in 85-92°C water for 5-6 minutes

(2) Features: steam heating, precise control of blanching temperature, overall lifting function, easy cleaning and maintenance.

(2) Features: steam heating, precise control of blanching temperature, overall lifting function, easy cleaning and maintenance.

(3) Technical parameters:

Dimensions: 10000*1200*1850mm

Transmission power: 0.75kw /380v/ 50Hz

Conveyor belt width: 1000 mm,

Water pump power: 3kw Lifting power of the upper cover: 1.1kw

Heating method: steam or natural gas or electricity can be customized, LNG gas heating

(4) Material disposal

Dimensions: 10000*1200*1850mm

Transmission power: 0.75kw /380v/ 50Hz

Conveyor belt width: 1000 mm,

Water pump power: 3kw Lifting power of the upper cover: 1.1kw

Heating method: steam or natural gas or electricity can be customized, LNG gas heating

(4) Material disposal

Drive motor: variable frequency speed regulation

Conveyor belt: stainless steel chain mesh belt

Frame: 50*50*2mm rectangular stainless steel square tube

Conveyor belt: stainless steel chain mesh belt

Frame: 50*50*2mm rectangular stainless steel square tube

Air drying dehydrator

(1) Purpose: To remove excess moisture on the surface of potato chips, and also to cool down potato chips quickly.

(2) Features: Strong air blowing, quickly drying the moisture of potato chips, easy to fry.

(3) Technical parameters:

Dimensions: 6000*1200*1150mm.

Total power: 4.5kw/380v/50Hz, drive: 0.75kw, fan: 12 conveyor belt width: 1000mm,

Drive motor: variable frequency speed regulation

Conveyor belt: stainless steel mesh belt

Frame: 50*50*2mm rectangular stainless steel square tube

(2) Features: Strong air blowing, quickly drying the moisture of potato chips, easy to fry.

(3) Technical parameters:

Dimensions: 6000*1200*1150mm.

Total power: 4.5kw/380v/50Hz, drive: 0.75kw, fan: 12 conveyor belt width: 1000mm,

Drive motor: variable frequency speed regulation

Conveyor belt: stainless steel mesh belt

Frame: 50*50*2mm rectangular stainless steel square tube

Continuous Fryer

(1) Application: It can be used for continuous frying of potato chips.

(2) Features: external heater, with oil storage tank, with coarse filter, with fume hood, adjustable temperature from 0-240°C, variable frying time, frequency conversion speed regulation. With external burner and heat exchanger, it is safer, more energy-efficient and has a longer service life.(3) Technical parameters:

Dimensions: 11000*1200*2100mm

Transmission power: 1.5kw/380v/50Hz

Oil pump: 2kw*2S set.

Lifting power: 2.2kw

Gas heating power: 800000kcal,

Conveyor belt width: 1000mm,

Fuel consumption: 70 cubic meters per hour of natural gas or 60 kg of liquefied petroleum gas.

Drive motor: variable frequency speed regulation

Frame: 50*50*2mm rectangular stainless steel square tube.

Fluidized freon single quick freezer

(1) Function: Quick-freezing French fries in a short time to keep the taste of fried French fries.

(2) Features: good freezing effect and large capacity.

(3) Technical parameters:

I1. Size: 15000*4000*2600mm

2. Freezing time: 10-80min (frequency conversion speed regulation)

3. Feed temperature: less than +15°C

4. Discharge center temperature: less than -18°C

5. The temperature in the freezer is lower than -30°C.

6. Conveyor belt width: 1200mm

7. Conveyor belt deceleration motor: 1.5kw (frequency conversion speed regulation), refrigerant R22 or R717

8. Compressor: Germany Bitzer brand, 2 sets. 125HP/set. (Working conditions +35℃/-42℃)

9. Installed power: 180kw (380V, 50HZ)

(2) Features: good freezing effect and large capacity.

(3) Technical parameters:

I1. Size: 15000*4000*2600mm

2. Freezing time: 10-80min (frequency conversion speed regulation)

3. Feed temperature: less than +15°C

4. Discharge center temperature: less than -18°C

5. The temperature in the freezer is lower than -30°C.

6. Conveyor belt width: 1200mm

7. Conveyor belt deceleration motor: 1.5kw (frequency conversion speed regulation), refrigerant R22 or R717

8. Compressor: Germany Bitzer brand, 2 sets. 125HP/set. (Working conditions +35℃/-42℃)

9. Installed power: 180kw (380V, 50HZ)

Automatic weighing and packaging machine type 420~820

(1) Purpose: automatic feeding, metering, bag filling, automatic sealing, date printing, nitrogen filling, with secondary packaging main

unit.

(2) Features: high precision, high efficiency, stable operation, stainless steel frame structure, easy maintenance and cleaning.

(3) Technical parameters:

Power: 3kw/220v/50hz

Size: 3658*2610*3650mm

Capacity: 30-40 bags/min, depending on the weight of each bag, 500g~5000g

unit.

(2) Features: high precision, high efficiency, stable operation, stainless steel frame structure, easy maintenance and cleaning.

(3) Technical parameters:

Power: 3kw/220v/50hz

Size: 3658*2610*3650mm

Capacity: 30-40 bags/min, depending on the weight of each bag, 500g~5000g

VIEW MORE

YOU MAY LIKE

Other Products

-

Automatic French Fries Production Line 100-500 kg/h French Fries Making Machine Potato Peeling Machine$14800.00 - $15600.00 / set

Automatic French Fries Production Line 100-500 kg/h French Fries Making Machine Potato Peeling Machine$14800.00 - $15600.00 / set -

Quality Assurance Fair Price LJFM-14 Potato Sweet Potato Knife Peeler$1500.00 / set

Quality Assurance Fair Price LJFM-14 Potato Sweet Potato Knife Peeler$1500.00 / set -

Professional big sale automatic french fries production line$5850.00 / set

Professional big sale automatic french fries production line$5850.00 / set