Factory Price Potato Chips Production Line Fresh Potato Chips Making Machine Potato Falkes Processing Plant

- $25000.00 / 1 - 1 sets

$20000.00 / >=2 sets - 1 set

- Henan Dabashan Automation Technology Co., Ltd.

- Henan, China

- Mr David Shao

PRODUCT DETAIL

| Core component warranty: | 1 year | Model Name: | DBS-APC200 |

| payment terms: | L/C, T/T | application: | restaurant food processing industry |

| Application fields: | Vegetable processing factory, snack food factory | Function: | fried food |

| product name: | Fry Pan | Marketing Type: | New Products 2020 |

| Package preview: | weight: | 1000 kg | |

| Applicable industries: | Food and Beverage Factory, Food Store | port: | Qingdao |

| Material: | stainless steel 304 | Mechanical function: | potato chip machine |

| Warranty: | 1 year | Video shipment inspection: | if |

| Origin: | Henan, China, Henan, China | Output product name: | Chips/French Fries |

| raw material: | fruit and vegetable | Packaging Details: | The normal packing is wooden case (size: L*W*H). |

| Dimensions (L*W*H): | 8500*1100*1200mm | Supply capacity: | 20 sets per week |

| After-sales service: | Video Technical Support | Main selling points: | low price good quality |

| Voltage: | 380V,380V | Health status: | new |

| Mechanical test report: | if | strength: | 50 kW |

| Showroom location: | not any | brand: | Daba Mountain |

| other service: | customized | Core components: | PLC, engine, motor |

| Heating type: | electrical |

Product Description

Fully automatic French fries/chips production line

This automatic potato chips production line is a perfect production line for automatic production of high-quality potato chips from cleaning, peeling, slicing, rinsing, blanching, dehydration, frying, deoiling, seasoning, packaging and other links.We can customize production lines with different capacities according to your requirements.Our potato chip machines will enable you to develop a wide variety of potato chips and produce them with consistent quality assurance.

production capacity

We can customize production lines with different capacities such as 100kg/h, 200kg/h, 300kg/h, etc.

Production Process

Potatoes→loading by elevator→cleaning and peeling→selecting→loading by elevator→slicing→rinsing→blanching→dehydration (vibration blowing)→frying→deoiling (vibration blowing)→seasoning→automatic weighing and packaging

Product Details

Elevating Conveyor

For lifting and conveying fresh potatoes to the next washing and peeling machine

Potato cleaning and peeling machine

SUS 304 stainless steel, high-quality nylon rollers, high efficiency and low cost

sorting conveyor

For manual handling of uncleaned spots and selection of defective potatoes

potato cutter

Cut the potatoes into slices, the thickness and size can be adjusted

bubble washing machine

Potato starch is washed off by high pressure water flow and water bubbles

Blanching machine

Blanching with hot water at 60-95 degrees to remove starch and protect color

Vibration Dehydration/Deoiler

The machine can fully remove the moisture on the surface of potato chips under vibration

air dryer

Pre-cooling by high-pressure wind to remove excess moisture in a short time

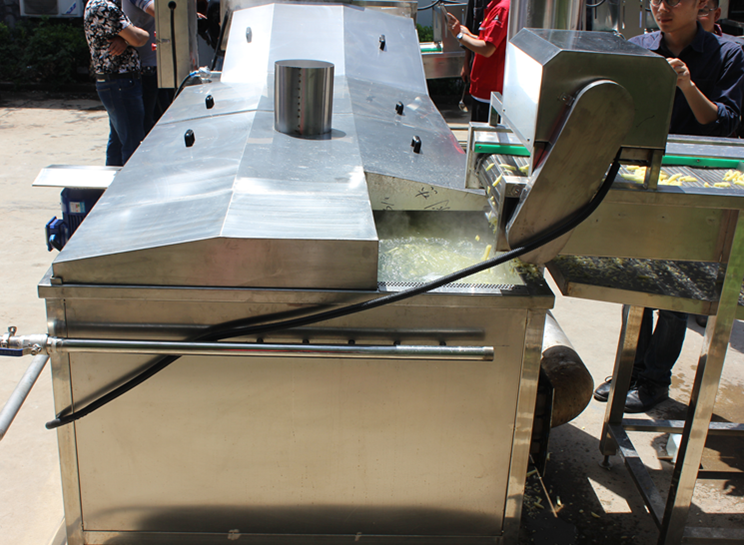

Continuous Fryer

Suitable for frying different kinds of snacks, the heating method can be customized

seasoning machine

Seasoned French Fries with Different Flavors

product specification

equipment | strength | aspect |

Elevator feeder | 0.75KW | 2600*1000*1600mm |

potato peeler | 3.37KW | 2800*1000*1400mm |

Select Conveyor | 1.50KW | 3000*800*950mm |

Elevator feeder | 0.75KW | 2000*1000*1800mm |

potato slicer | 1.50KW | 800*810*750mm |

rinse machine | 4.5KW | 4000*1200*1300mm |

Blanching machine (gas heating) | 3.70KW | 4000*1200*2200mm |

Vibrating dehydrator | 0.36KW | 1800*1000*1100mm |

Air blowing dehydrator | 6.00KW | 4000*1200*1400mm |

Elevator feeder | 0.75KW | 2000*1000*1300mm |

Fryer (External Gas Heated) | 5.94KW | 6000*1200*2200mm |

oil storage tank | 1.50KW | 1200*1200*1800mm |

fuel tank | 6.00KW | 1380*600*1580mm |

oil filter | 1.50KW | 700*700*1000mm |

Air blown degreaser | 6.00KW | 4000*1200*1400mm |

Elevator feeder | 0.75KW | 2000*800*2200mm |

seasoning machine | 1.50KW | 1500*900*1500mm |

Elevator feeder | 0.55KW | 1500*800*1000mm |

Packing Machine | 6.00KW | 4500*3000*3750mm |

Packaging and Shipping

We provide perfect packaging so that the product reaches its destination safely

some customers

VIEW MORE

YOU MAY LIKE