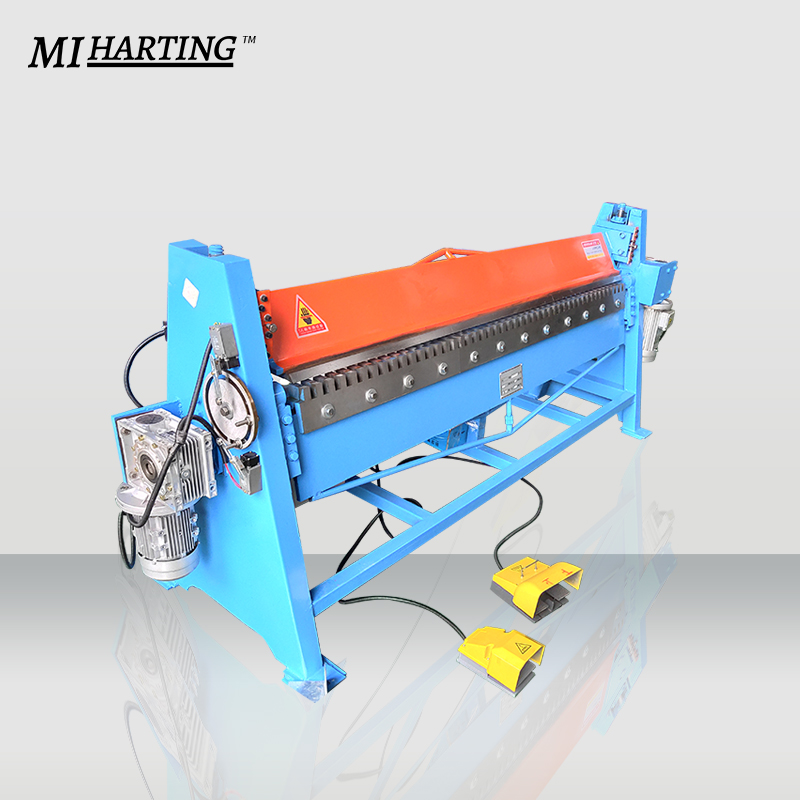

2.5*3000 stainless steel sheet metal electric hydraulic bending machine

- $3600.00 / 1 - 9 sets

$2000.00 / >=10 sets - 1 set

- Anhui Harting Machinery Technology Co., Ltd.

- Anhui, China

- Ms Kitty Gui

PRODUCT DETAIL

| Applicable industries: | Apparel Stores, Retail Stores, Food and Beverage Stores, Printing Stores, Machinery Repair Shops, Manufacturing Plants, Farms, Advertising Agencies, Restaurants, Construction Works, Building Materials Stores | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Core component warranty: | 1 year | Warranty: | 1 year |

| usage: | sheet metal folding | After warranty service: | Video technical support, no service, online support, spare parts, on-site maintenance and repair services |

| Folding material: | sheet metal | Material: | sheet metal |

| Applicable thickness: | 0.3-1.5mm | application: | manual folding machine |

| Name: | sheet metal bending | Weight (kg): | 8500 |

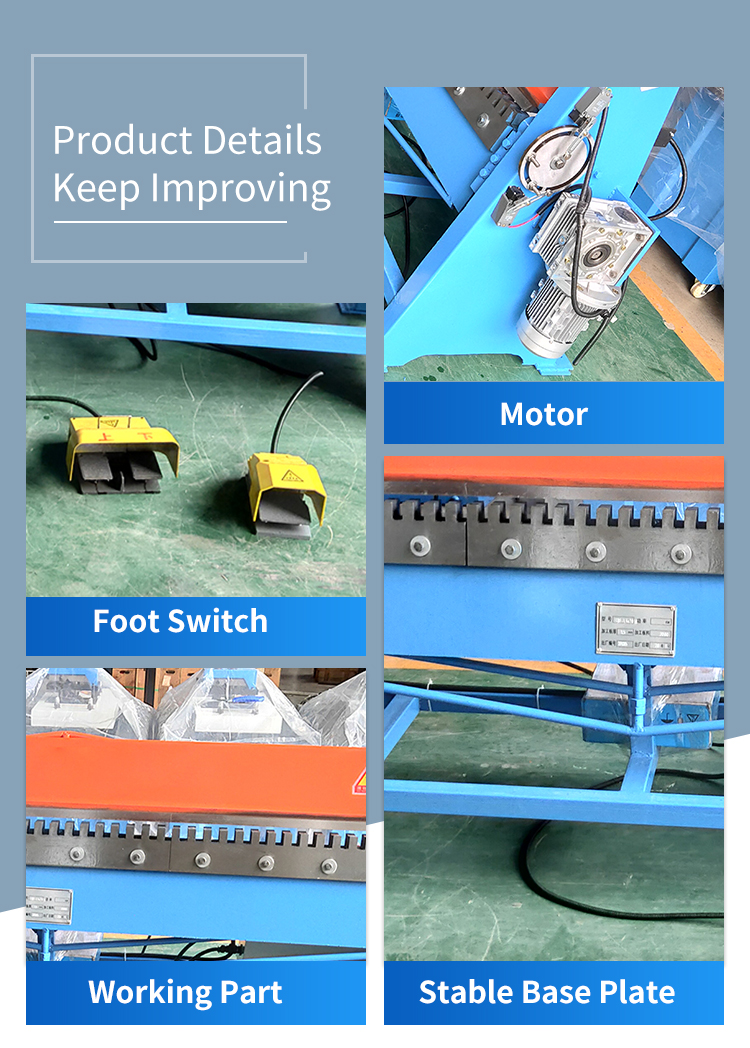

| Marketing Type: | New Products 2020 | Core components: | pressure vessel, gear |

| Packaging Details: | Waterproof Plastic Film Tray Plastic Film Plywood Box Plastic Film 2.5*3000 Stainless Steel Metal Sheet Electric Hydraulic Bending Machine | Dimensions (L*W*H): | 3180*800*1320mm |

| Certification: | ce | After-sales service provided: | Online support, on-site maintenance and repair services, free spare parts, video technical support |

| product name: | Sheet Metal Bending Machine | Showroom location: | not any |

| Video shipment inspection: | if | Supply capacity: | 8 sets per month |

| Material/Metal Processing: | Aluminum alloy, ALLOY, stainless steel, carbon steel, aluminum | Bending Thickness(mm): | 0.5 - 4mm |

| Origin: | Anhui, China | Main selling points: | high security level |

| Local service location: | not any | Mechanical test report: | if |

| port: | Shanghai | brand: | Mihatin |

| Operation: | easy car | automation: | automatic |

| Key words: | Sheet Metal Bending Machine | Health status: | new |

| Bending length: | 3000mm | Bending Length(mm): | 3000mm |

Product Description

2.5*3000 stainless steel sheet metal electric hydraulic bending machine

A bending machine is a machine tool used to bend sheet and sheet material, most commonly sheet metal. It forms a predetermined bend by

The workpiece is clamped between matching punches and dies.

The workpiece is clamped between matching punches and dies.

Stroke length, distance between frame uprights or side shells, back gauge distance and working height.

1. Heavy duty steel frame provides precise flex

2. Extended fingers allow bending of pans or boxes to a depth of 200mm

3. There are scales on both sides of the machine, which saves the guess work of bending angle

4. Ground segmented fingers can be repositioned for multiple applications

5. Safety roof beam support stop lever located on the right side of the machine

6. Fast beam adjustment for different material thicknesses

7. Including rear manual gauge

2. Extended fingers allow bending of pans or boxes to a depth of 200mm

3. There are scales on both sides of the machine, which saves the guess work of bending angle

4. Ground segmented fingers can be repositioned for multiple applications

5. Safety roof beam support stop lever located on the right side of the machine

6. Fast beam adjustment for different material thicknesses

7. Including rear manual gauge

Model | Minimum chamfer angle(°) | Plate thickness (mm) | Maximum board width(mm) | Weight (kg) | length (mm) | Width (mm) | Well) | ||

WS-1.5*1300 | 60 | 0.3-1.5 | 1300 | 360 | 1980*800*1320 | ||||

WS-1.5*1500 | 60 | 0.3-1.5 | 1500 | 380 | 2180*800*1320 | ||||

WS-1.5*2000 | 60 | 0.3-1.5 | 2000 | 440 | 2680*800*1320 | ||||

WS-1.5*2500 | 60 | 0.3-1.5 | 2500 | 560 | 3180*800*1320 | ||||

WS-1.2*3000 | 60 | 0.3-1.2 | 3000 | 680 | 3860*800*1590 | ||||

TDF-1.5*1500 | 60 | 0.3-1.5 | 1500 | 450 | 2180*800*1320 | ||||

TDF-1.5*2000 | 60 | 0.3-1.5 | 2000 | 550 | 2680*800*1320 | ||||

TDF-1.5*2500 | 60 | 0.3-1.5 | 2500 | 660 | 3180*800*1320 | ||||

Specification

VIEW MORE

YOU MAY LIKE