20 Ton Pneumatic Workshop Press

- $162.00 /piece

- 1 piece

- Xianxian Zhongtuo Hardware Tools Co., Ltd.

- Hebei, China

- Mr quanchao zhou

| Energy source: | pneumatic | Showroom location: | not any |

| CNC or not: | normal | weight: | 50 kg |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Supply capacity: | 1000 sets per month |

| brand: | Zhongtuo | Weight (ton): | 0.052 tons |

| port: | Tianjin | Type of machine: | 20 Ton Pneumatic Workshop Press, Double Column Hydraulic Press |

| Health status: | new, new | Packaging Details: | carton |

| Core components: | pressure vessel | Motor power (kW): | 10 kW |

| system: | normal | Nominal force (kN): | 1 kN |

| Material: | Stainless steel | Warranty: | 6 months |

| Main selling points: | multifunctional | Voltage: | 220 volts |

| Core component warranty: | 6 months | Resilience (kN): | 1 kN |

| Marketing Type: | normal product | Local service location: | not any |

| Mechanical test report: | if | product name: | Hydraulic workshop presses |

| Key words: | workshop news | Origin: | Hebei china |

| capacity: | 20 tons/10 tons | Applicable industries: | Mechanical Repair Shop, Construction Work |

| Video shipment inspection: | if | After warranty service: | spare parts |

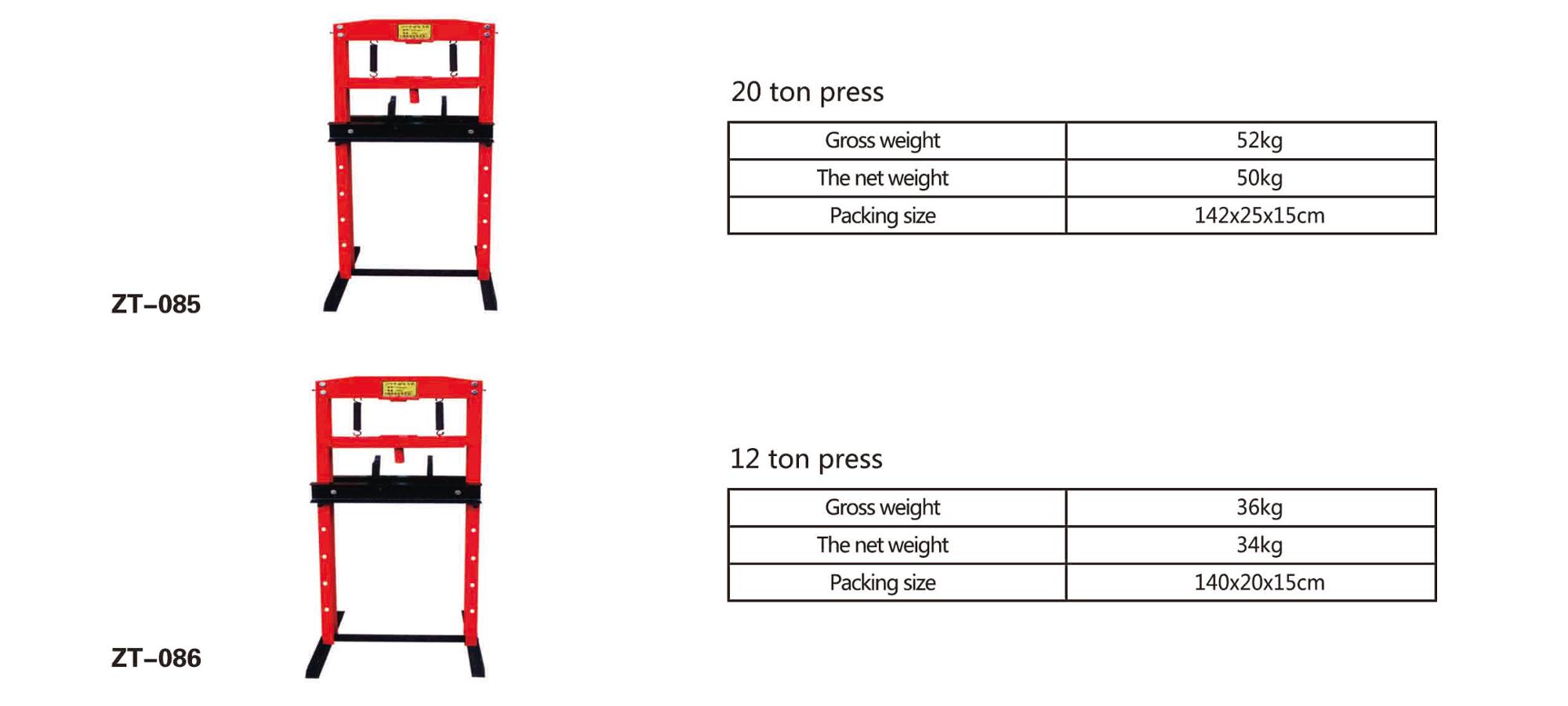

12 Ton Hydraulic Workshop Press

Specification

|

model |

20 tons |

| gross weight | 52 kg | |

| net weight | 50 kg | |

| Package Size | 142*25*15cm |

All models and specifications

The press is a general-purpose press with a delicate structure. Presses can be widely used in cutting, punching, blanking, bending, riveting and forming processes. The presses produced by our factory are produced and processed for enterprises that have this demand, and the presses can be purchased according to your needs.

product description:

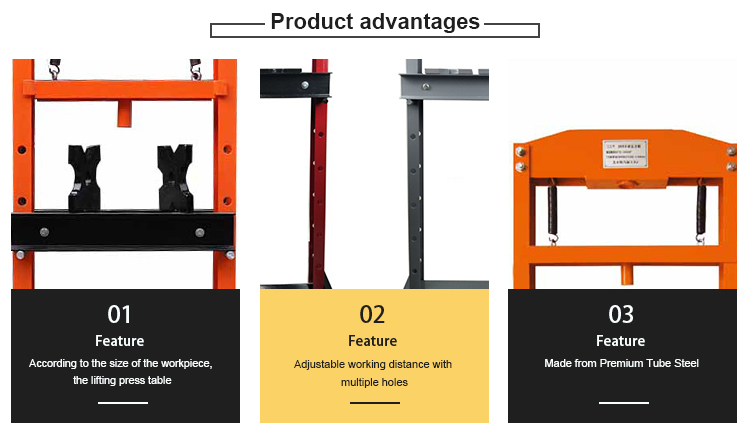

1) Manual press is a small series of presses. It has a door frame, simple structure, easy disassembly and assembly, and adjustable working distance. It is suitable for various pressure work such as integral shaft and pressure accessories.

2) Main structure: door frame, jack

3) Use features: According to the size of the two pieces, the press table can be lifted up and down, 20T, with seven small holes, and there is a jack for adjusting the working distance.

4) Assembly before use: For the convenience of packaging and transportation, the whole machine is completely unpacked. Assemble according to the picture before use, the site should be flat, first assemble into a frame, pay attention to vertical and parallel, the fasteners should be tightened, and then install the jack to use.

Other Products

-

2T 5T Hydraulic Steel Car Ramp Jack Lift$35.00 - $48.00 / piece

2T 5T Hydraulic Steel Car Ramp Jack Lift$35.00 - $48.00 / piece -

6 Ton Hydraulic Workshop Press$50.00 / piece

6 Ton Hydraulic Workshop Press$50.00 / piece -

Easy-to-operate manual spring compressor$56.00 / set

Easy-to-operate manual spring compressor$56.00 / set -

100A 200A Copper Plated Car Battery Clip$0.20 / piece

100A 200A Copper Plated Car Battery Clip$0.20 / piece