300g plastic material vacuum loader industrial plastic pellet automatic hopper loader for injection molding machine

- $200.00 / 1 - 4 pieces

$190.00 / 5 - 9 pieces

$180.00 / >=10 pieces - 1 piece

- Guangdong Xiaojuren Machinery Co., Ltd.

- Guangdong, China

- Ms Ellie He

PRODUCT DETAIL

| Showroom location: | Turkey, UK, Vietnam, Philippines, Brazil, Indonesia, Pakistan, India, Russia, Thailand, Japan, Malaysia | brand: | Hengju |

| brand: | Hengju | Key words: | Vacuum feeding machine |

| Static air pressure: | 1300mm/water column | Warranty: | 1 year |

| Conveying capacity: | 200(liter/hour) | Health status: | new |

| Applicable industries: | Manufacturing plant, plastic extrusion molding, plastic blow molding, plastic injection molding, plastic industry | Video outbound inspection: | if |

| product name: | automatic loader | weight: | 14kg |

| Model: | 300g | Package preview: | |

| Weight (kg): | 14kg | Packaging details: | Customization |

| Material: | Stainless steel | Core component warranty: | 1 year |

| Core components: | Engine, bearing | Voltage: | 380V |

| capacity: | 7.5kg | Mechanical test report: | if |

| Name: | automatic loader | port: | Guangzhou |

| Dimensions (length*width*height): | 38*38*60 | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Supply capacity: | 100 pieces per week | Place of origin: | Guangdong, China |

| Capacity (kg/hour): | 1000kg/hour | application: | Plastic industry |

Model | HAL-300G |

Motor type | carbon brush |

Motor specifications | 1.2-1.5KW 1φ |

Conveying volume (L/h) | 200 |

Static air pressure (mm/h2o) | 1300 |

Liquid storage volume (L) | 7.5 |

Material diameter (mm) | φ38 |

Hoses specifications (mm) | φ38mm x 3.5m 1 piece |

Machine size (mm) | 206*330*454 |

Packing size (mm) | 380×380×600 |

Approximate net weight (kg) | 14 |

300G hopper loader

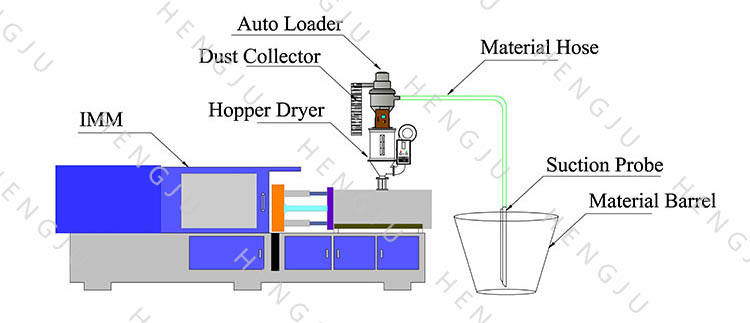

The 300G hopper loader is mainly used in the plastic processing industry to absorb plastic raw materials and then transport them to injection molding and other processing equipment.Molding machines, extruders and blow molding machines for production. Controlled by a line control controller, the loading work is automatically completed.

feature:

1. Small in size and light in weight, it can be directly installed on a hopper dryer or other container for automatic loading.

2. Using high-speed rectifier motor, compact size,Strong suction power.

3. Microcomputer control. Overload and material shortage alarms.

4.EquipmentFilter and dust bag, can filter and remove dust in raw materials.

5. It is controlled by a wire controller and can be placed at a high place. The control can be set under the machine, which is convenient and fast.

2. Using high-speed rectifier motor, compact size,Strong suction power.

3. Microcomputer control. Overload and material shortage alarms.

4.EquipmentFilter and dust bag, can filter and remove dust in raw materials.

5. It is controlled by a wire controller and can be placed at a high place. The control can be set under the machine, which is convenient and fast.

Working principles:

The air is sucked in from the suction port of the main body of the feeder through a suction fan, generating negative pressure, causing the air in the suction pipe to flow, driving the plastic raw materials into the suction pipe, and then filtering and removing dust through the filter, and finally transported to the target equipment. Such as injection molding machines, extruders, blow molding machines, etc.

Company Profile:

Since its establishment, Hengju has been focusing on the research and development of dehumidification and drying, ingredient mixing, and central conveying systems to make products closer to customer needs and customize complete automation solutions for customers.

Hengju Machinery can provide you with complete factory automation solutions and central chiller design. We have 15 years of industry experience and a self-built factory of 8,000 square meters, providing services to hundreds of companies, tailor-made solutions, free design renderings, and 24-hour online communication services.

Hengju Machinery can provide you with complete factory automation solutions and central chiller design. We have 15 years of industry experience and a self-built factory of 8,000 square meters, providing services to hundreds of companies, tailor-made solutions, free design renderings, and 24-hour online communication services.

With strong professional technology and stable quality, it has won high praise from customers at home and abroad. The industry covers auto parts, chemicals, granulation, new energy, new materials, etc. In biodegradable plastics such as PLA, PBAT and

Pipe/sheet/cable extrusion and other fields!

VIEW MORE

YOU MAY LIKE