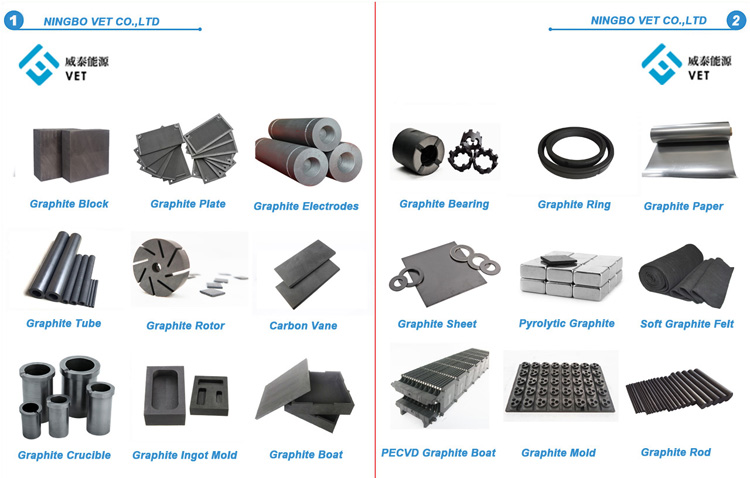

5oz Gold Rectangular Rod Casting Refining High Density Graphite Ingot Graphite Mold

- $3.00 /piece

- 1 piece

- Ningbo Miami Advanced Material Technology Co., Ltd.

- Zhejiang, China

- Ms Xianer Yeh

| payment terms: | L/C, Western Union, T/T, MoneyGram | Bending strength: | 30~45MPa |

| Gain size: | <=325 mesh | Bulk density (g/cm3): | 1.85 g/cm3 |

| Resistance (μΩ.m): | 8-10 ohms | product name: | graphite mold |

| brand: | veterinary | model: | Mold 1004 |

| technology: | Sintering mold | Material: | High purity graphite |

| Origin: | Zhejiang, China | Size and shape: | custom made |

| Ash content: | 0.1% max | Packaging Details: | Wooden box or according to customer's requirement |

| port: | Ningbo/Shanghai/Shenzhen | Porosity(%): | 12% max |

| aspect: | custom made | application: | Melting and Sintering Metals |

| Supply capacity: | 10000 pieces per month | Compressive strength: | 65 MPa |

| Certificate: | ISO9001:2015 | sample: | if |

5oz Gold Rectangular Rod Casting Refining High Density Graphite Ingot Mold

size:

Outer dimension 25.4*127*203.2mm

Inside: 5.7 depth*bottom 25.4*50.8mm

Shape: as shown in the picture

Capacity: 5 oz gold

Material

|

Bulk density |

1.80 g.cubic centimeter |

|

resist |

11-13 meters |

|

Shore hardness |

55 |

|

CET-4 |

4.8×10*6/C |

|

Compressive strength |

90MPa |

|

Bending strength |

40MPa |

application

Gold, silver, copper, precious metal casting

Helpful tips for working with ingot molds:

1: Heat the graphite mold to 250c-500c to avoid any damage in the process and get higher quality results.

Heating temperatures may vary for different materials.

2: Put the scrap into the graphite crucible and heat the graphite crucible until the metal reaches a liquefied state.

Pour molten metal into preheated molds.

3: Graphite molds can last for multiple pours, depending on the temperature and the type of metal you are encapsulating.

4: If you experience demoulding problems, you can freeze the mold to demould the ingot.

Note: These instructions can be used for all sizes of graphite ingot molds.

These molds can be used to cast gold, silver, copper, platinum, aluminum, arsenic, iron, tin...

WARNING: The mold and metal will be very hot. Please handle with care.