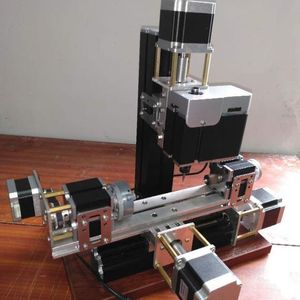

All-metal Miniature 4-axes CNC Milling Machine for Modelmaking Hobbyist

- $1200.00 /piece

- 1 piece

- Xi'an Zhengrui Education Equipment Co., Ltd.

- Shaanxi, China

- Mr Andy An

| Table Travel (X) (mm): | 30 mm; | Place of Origin: | Shaanxi, China; |

| No. of Spindles: | Single; | Range of Spindle Speed(r.p.m): | 5000 - 12000; |

| Key Selling Points: | Energy saving; | Applicable Industries: | Home Use,Retail,Advertising Company,Teaching&Modelmaking; |

| Spindle Taper: | ISO40; | Repeatability (X/Y/Z) (mm): | 0.01; |

| Table Travel (mm): | 1-50mm; | Port: | Shenzhen/Guangzhou/Shanghai; |

| Dimension(L*W*H): | 320*280*360mm; | Year: | 2019; |

| Showroom Location: | India,Russia,Kazakhstan,Uzbekistan; | Voltage: | 110-240V; |

| CNC Control System: | FANUC; | Max. Table Load(kg): | 5 kg; |

| Positioning Accuracy (mm): | 0.01; | Weight (KG): | 60; |

| After-sales Service Provided: | Free spare parts,Online support,Video technical support; | Certification: | CE/ISO/CCC; |

| Machining Capacity: | Heavy Duty; | Positive clamping size of 3-jaw chunk: | 15mm; |

| CNC or Not: | CNC; | Condition: | New; |

| Table Travel (Z) (mm): | 10 mm; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Reverse clamping size of 3-jaw chunk: | 30mm; | Feature: | Miniature/Modularity/Inteligent; |

| Brand Name: | ZR; | Warranty: | 1 Year; |

| Type: | VERTICAL; | Number of Axes: | 4; |

| Table Travel (Y) (mm): | 40 mm; | Power (kW): | 0.06; |

| Local Service Location: | India,Russia,Kazakhstan,Uzbekistan; | Model Number: | ZRZX3060X; |

| Packaging Detail: | Corrugated paper box+ EPE foam inner packing; | Supply Ability: | 500 Pieces per Month; |

| Payment Terms: | L/C,T/T,Western Union,Paypal; |

All-metal Miniature 4-axes CNC Milling Machine for Modelmaking Hobbyist

Technical Parameter:

1,Motor speed: 12,000 rpm.

2,The input voltage / current / power: 12 VDC / 5A/60W

3,The slider travels: X axis 120mm, Y axis 30mm, Z axis 30 mm, A axis 360°

4,Chunks: 1-6 mm

5,The clamping size of 3-jaw chunk: positive 15mm, reverse 30mm

6,Processed material: solid wood, engineering plastic, wax, non-ferrous and soft metal.

Product Characteristic:

Main parts are configured with metal structure and no plastic components in the whole machine body, such as motor box, headstock, slider, machine bed, gear, side cover, connection block, tailstock, countershaft, drive belt cover etc.

Control system: Intelligent offline CNC system, apply the latest hardware & software design to work more stable and safe. Handheld operation panel is available.

Programmable format: Standard G code/PLT file:

It is compatible with the most popular CAD/CAM software, such as Type3, Artcam, UG, Pro/E, MasterCAM, Cimatron and Maintop. All of them could generate G code and cutting path, which could be simulated to the whole procedure of CNC experiment and CNC machine tool operation trainings.

High-precision stepping drive system and high-precision screw transmission

The system supports the control mode of 2/3-axes Simultaneous Motion

Multi-I/O points control mode: standard I/O signal nodes have 8 input and 4 output signals respectively

Feature with breakpoint memory and appointed file content processing. 8 different breakpoint machining information can be saved.

The multi-coordinate systems have memory function, total 9 working coordinate systems available. The user could shift among them and save the machining origin information in each coordinate system.

The running frequency/speed of spindle could be adjusted when machining. As request, it is set to 1 to 8 adjustable position that be activated by pressing button without pausing.

The running &machining speed could be adjusted by pressing the button of speed multiplier. The value of speed multiplier is increased or decreased by 0.1 each time and range from 0.01 to 1

Under the mode of manual operation mode, system provides 3 type motions of continuous, step (jog) and distance, making manual operation more simple and convenient.

Built-in 512M memory, equipped with USB communication port, super-fast file transfer efficiency, can directly read files by U disk and card reader.

The unique hand-held appearance could be operated by one hand. Featuring with LCD panel and 24-key buttons, the operation is more intuitive &flexible, no longer dependent on the computer, fully offline operation.

Self-detection function: the system comes with I/O port signal detection function which is convenient for remote maintenance.

Multi-language display: Simplified Chinese, Traditional Chinese, English, Russian, French, etc. It could be customized according to actual demand.

The system supports fully automatic dynamic upgrade, which is convenient for remote operation and maintenance.

FTP network transfer file function: when U disk is damaged, you can quickly transfer files to the system through the network cable.

Outside vacuum plastic bag+Corrugated paper box,inner EPE foam packing

DHL/Fedex/TNT/UPS and special cargo service are all available, the lowest rate will be quoted for long term cooperation

After receiving the payment, we will arrange the delivery within 3-5 wokring days accordingly

Question1: What's the usage of ZR miniature machine tools?

The miniature machine tools have the same features as big industrial machines, the only differences are their size and the 12V drive. You can use it for DIY model making and some little crafts, which is also able to process hard wood, soft metal, alloy etc...

Based on its modularity and the child friendly use, that's ideal& creative product to inspire children hand-on skill &innovative ability.

Question 2: Is it easy to assemble and operate the miniature machine tools?

What we provided is the installed complete machine tools, meanwhile, there is full set of English manual & guide videos to show you how to use it smoothly. If you still have any query, please contact us by e-mail / whatsapp/ mobile phone for online service.

Question 3 : How about the after sales service?

Firstly, quality guaranteed by the authoritative certificate of CE, RoHS, FCC , ISO9001:2008

Second, free spare parts and one year warranty

Third, regional agent service system & 24*7hrs on-line technical support available