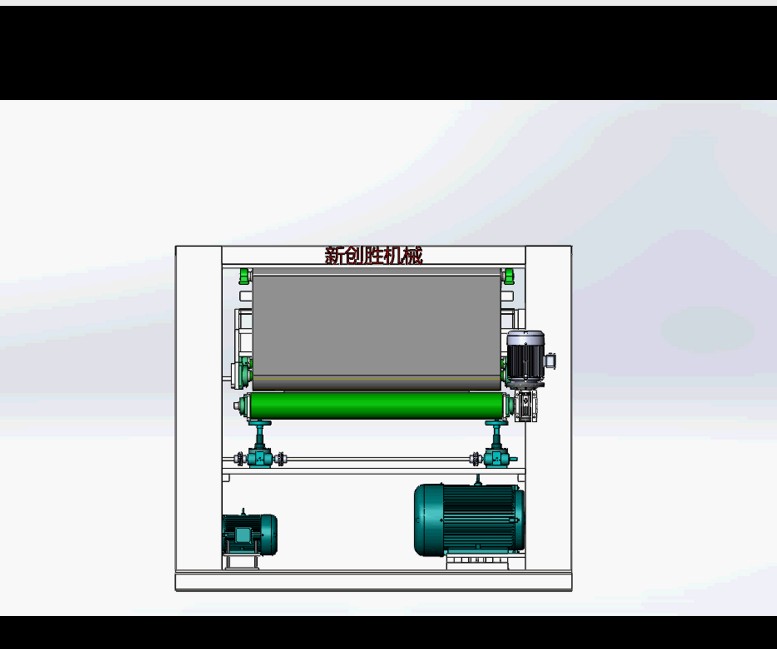

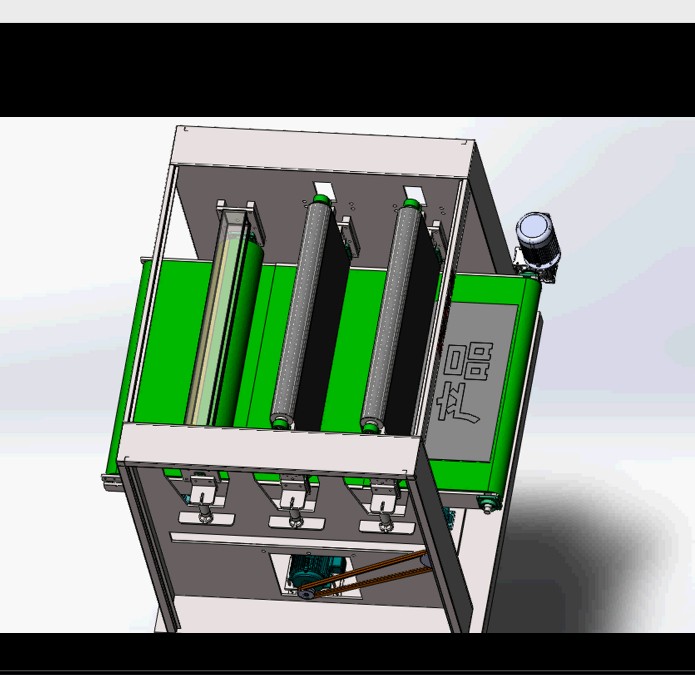

Automatic machine for polishing metal plates (1500mm-1.5m width)

- $500.00 / 1 - 9 pieces

$100.00 / >=10 pieces - 1 piece

- Foshan Fumaite Trading Co., Ltd.

- Guangdong, China

- Ms zhang linyan

| After-sales service provided: | Overseas service center available | brand: | CS |

| Effect after polishing: | mirror reflection | Spindle speed: | 1800 rpm |

| Total power: | 13.25kw | Packaging Details: | Standard export packing - wooden case |

| main motor power: | 11KW-4 class | Processing capacity: | 350v 50hz |

| payment terms: | L/C, T/T | Model: | CS-1500 |

| port: | Guangzhou Port | Input speed: | 1-5m/m (adjustable) |

| Features: | Grinding and polishing of metal surfaces | Specifications of polishing consumables: | Outer diameter 250*thickness*500mm |

| Supply capacity: | 500 pieces per month | place of origin; place of origin: | Guangdong, China |

| Polishing consumables: | Hemp wheel, sisal wheel, cloth wheel, flap, nylon wheel | Shipping Details: | Within 30 working days after receiving the deposit |

| model: | CS-C1500 |

Metal plate polishing machine

It is suitable for single-sided grinding and polishing of metal surfaces in various industries such as square pipes and metal sheets. The polishing machine is especially suitable for metal polishing and rust removal in the furniture manufacturing industry and metal polishing in the display rack manufacturing industry.

| Abrasive Belt: Circumference*Thickness: 150mm*2100mm, 250mm*2100mm; 400=1380, 600=1380, 800=1380, 1000=1600, 1300=1600 | |

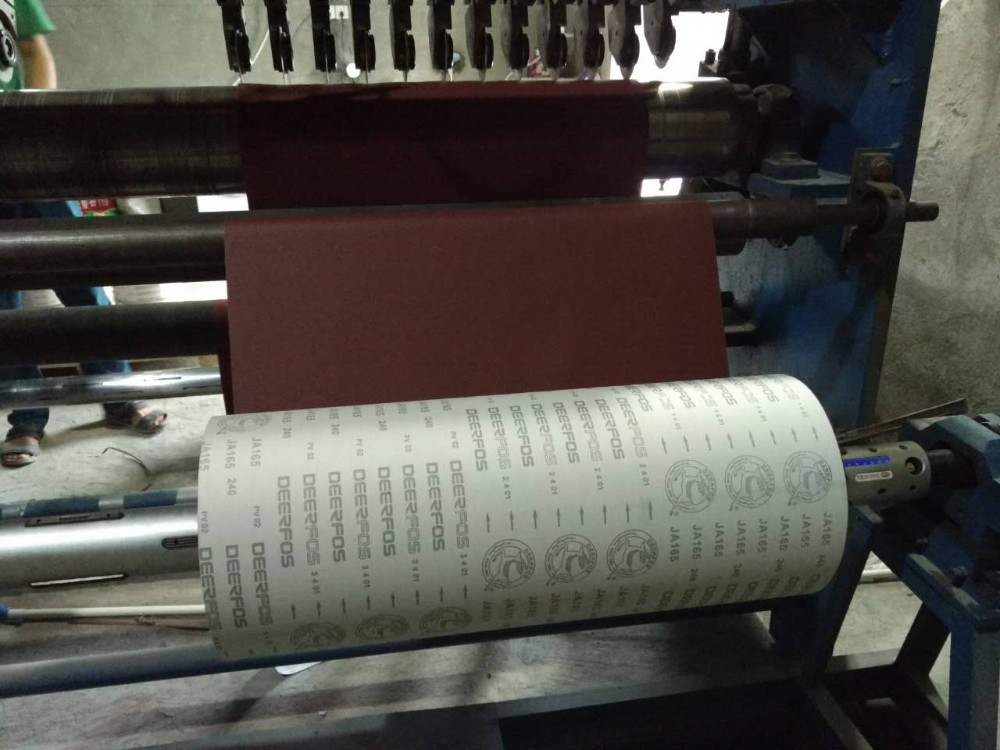

Supplies use

How to use consumables to get the desired finish with this automatic stainless steel watch polisher?

First, we can give you options at every point of the polishing process with a 3-level polishing range and a range from 2B finishing to 100% 8K mirror finishing. Additionally, you should know how to use the correct consumables and polishing process to achieve a profitable cost and get the correct finish as needed.

Use the louver to remove scratches and sand holes on the surface of the workpiece

Obtaining a matt finish on sheet metal surfaces with sisal/hemp wheels

Mirror finishing with hard/soft cloth wheels

Usually sisal/hemp wheels with purple polish; hard cloth wheels with green polish; soft cloth wheels with white polish

Our most professional packaging

Air Cargo and Express

and international shipping

Foshan Fumet Industrial Brush Products Co., Ltd. was established in 1992, and the company covers an area of 5,000 square meters. Guided by science and technology, the company specializes in product design, development, production, testing, sales and service. Committed to providing industrial brush series products and overall solutions for surface treatment of parts in industries such as automobiles, air conditioners, shipbuilding, and electronics.

Our company has two trademarks YL and WEILITE, YL's label is more popular in Guangdong and China. After years of continuous development and growth, our company's products are not only sold well in China, but also exported to more than 10 countries such as Europe, America, and Southeast Asia. At the same time, we have won unanimous praise from customers for our high-quality product quality and excellent quality. reputation.

We always adhere to people-oriented, strive to be the first to create excellence, we always believe that quality creates a brand, and integrity creates a brand. Strive to become a first-class domestic and world-class industrial brush production and system service platform brand.

customer

pre-sale service

1> Provide free consultation on equipment

2> Provide standard equipment and flow chart

3> According to the special requirements of customers, we provide reasonable solutions and free design to help select equipment.

4> Welcome to visit our factory

Sale service

1> Check the machine before leaving the factory.

2> Overseas installation and commissioning of equipment.

3> Train front-line operators.

After-sales service

1> 24 hours online service

2> Provide the video of installing and debugging the equipment

3> Provide technical exchanges

Q1. What is your packing condition?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have a legally registered patent,

After getting your letter of authorization, we can pack the goods in your branded boxes.

Q2. What are your payment terms?

A: T/T 30% as deposit, 70% before delivery. We will show you the photos of the products and packages

before you pay the balance.

Q3. What are your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the situation

About the item and quantity of your order.

Q5. Can you produce according to samples?

A: Yes, we can produce with your samples or technical drawings. We can manufacture molds and fixtures.

Q6. What is your sample policy?

A: We can provide samples if we have ready parts in stock, but customers have to pay the sample cost and

Courier fees.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

Answer: 1. We keep good quality and competitive price to ensure our customers benefit;

2. We treat every customer as a friend, do business sincerely, make friends,

no matter where they come from.