Automatic mattress laminating machine

- $34780.00 / >=5 sets

- 5 sets

- Jiangsu Kuntai Machinery Co., Ltd.

- Jiangsu, China

- Ms Annie Lv

PRODUCT DETAIL

| Video external inspection: | if | Mechanical test report: | if |

| Health status: | new | port: | Shanghai |

| Core components: | motor | Applicable industries: | manufacturing plant |

| Roller width: | 2000mm, 2200mm, can be customized | Dimensions (L*W*H): | customizable |

| weight: | 8000 | Marketing Type: | normal product |

| Showroom location: | not any | Packaging Details: | Automatic Mattress Laminating Machine Standard Export Container |

| Voltage: | customizable | Certification: | CE certificate |

| After-sales service provided: | Engineers can repair machinery overseas | Production capacity: | automatic |

| strength: | customizable | brand: | Kuntai |

| color: | RAL9002, RAL5005, can be customized | Warranty: | 1 year |

| payment terms: | L/C,D/P,D/A,T/T | Supply capacity: | 60 sets of automatic mattress laminator per month |

| Core Components Warranty: | 1 year | Packaging Preview: | |

| place of origin; place of origin: | Jiangsu, China |

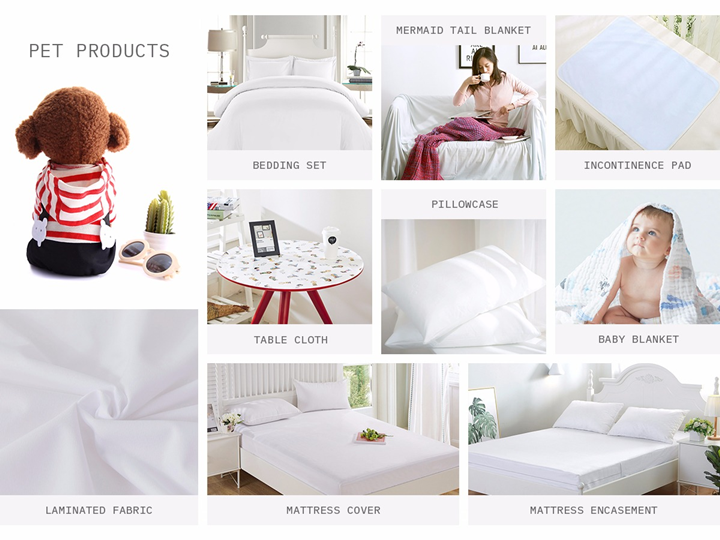

cloth laminating machine

Mattress Laminating Machine

Hygienic material laminating machine

usage:It is used for the lamination and lamination of various materials such as textiles, non-woven fabrics, waterproof and breathable membranes, and is especially suitable for lamination of terry cloth, sanitary materials, and waterproof and breathable membranes.

feature:

- Suitable for solvent-based glue or PU glue.

- With this laminating machine, the material is firmly bonded, and the product is soft, comfortable, washable and breathable.

- Optional:The laminating machine is controlled by a programmable logic controller system, with a touch screen and modular design structure, and is easy to operate.

- International famous brand motors, frequency converters, electrical components, thermostats and other components can be installed, and the machine performance is stable.

- The tension-free unwinder makes the laminate smooth and flat, ensuring a good bond.

- The fabric and film opener also allows for a smooth, level feed of material.

- Optional:For four-way stretchable fabrics, a special fabric conveying system can be installed on the laminating machine.

- Optional:The parallel centering device ensures that the material is fed in sequence.

- The specially designed gluing system controls the amount of glue and ensures the accuracy.

- Automatic edge trimmer and edge waste remover facilitate automatic operation and save labor.

- Cooling unit enhances good lamination bond.

- The final laminate can be rewound into small or large rolls.

- Low maintenance cost and low operating noise.

- Advanced technology, safe quality control and satisfactory after-sales service make our laminating machine the first choice for domestic and foreign customers.

Technical data:

Width: 1200-3600mm

Speed: up to 50m/min

Adhesives: PU adhesives and solvent-based glues

Coating thickness: 3-500g/m2 (according to the number of glue rollers)

application:

Packaging and Shipping

Laminating machine

Inner packaging: protective film, etc.

Outer packing: standard export container

- Machines packed with protective film and loaded into export containers;

- English version of the operation manual and technical information;

- One-year wearing parts;

- Toolkit

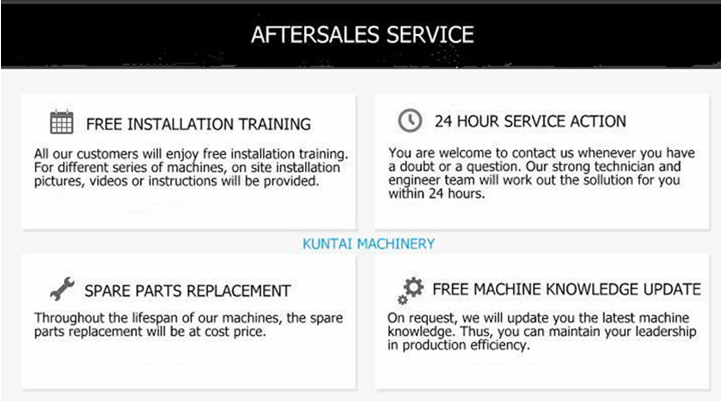

our service

On-site installation and operation training for engineers

VIEW MORE

YOU MAY LIKE

Other Products

-

Fabric, Foam, Velvet Automatic Fabric Coating Machine Made in China$69000.00 - $69800.00 / set

Fabric, Foam, Velvet Automatic Fabric Coating Machine Made in China$69000.00 - $69800.00 / set -

Hot Melt Adhesive Laminating Machine/Cloth Laminating Machine$64000.00 - $72500.00 / set

Hot Melt Adhesive Laminating Machine/Cloth Laminating Machine$64000.00 - $72500.00 / set