Best Selling Repairable DK7735 Wire Cutting Machine Automatic Wire Cutting EDM Machine

- $5500.00 / 1 - 4 sets

$5100.00 / >=5 sets - 1 set

- Taizhou Tongfang Cnc Machine Tool Co., Ltd.

- Jiangsu, China

- Mr siyuan chen

PRODUCT DETAIL

| Type of machine: | Wire EDM | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Weight (kg): | 1200 | Health status: | new |

| Maximum cutting speed: | ≥120mm²/min | Main selling point: | easy to operate |

| Core components: | Screw, guide rail, stepper motor, electronic control system | Workbench stroke: | 350*450mm |

| Video external inspection: | if | Core Components Warranty: | 1 year |

| Wire diameter: | 0.10-0.2mm | Packaging Details: | standard packaging |

| working desk size: | 360*630mm | Packaging Preview: | |

| year: | 2021 | Supply capacity: | Price of 300 CNC high-speed DK7745J wire EDM machines per month |

| product name: | Wire EDM | maximum. load: | 300kg |

| Optimum machined surface roughness: | R≤2.5μm | Mechanical test report: | if |

| port: | Shanghai/Ningbo | Precision: | 0.015mm |

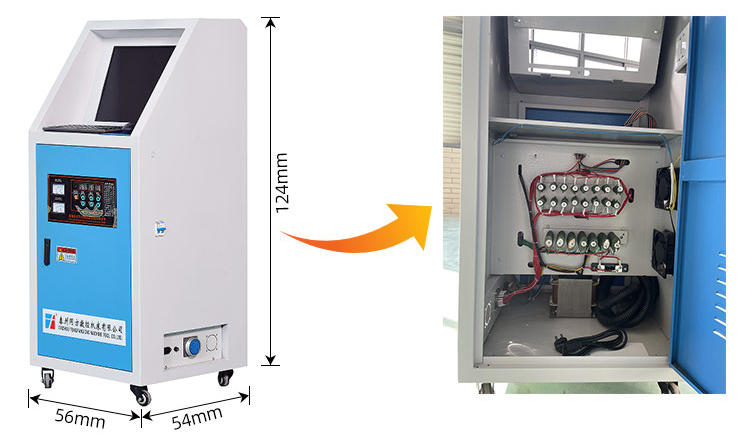

| place of origin; place of origin: | Jiangsu, China | Dimensions (L*W*H): | 1240*1170*1400mm |

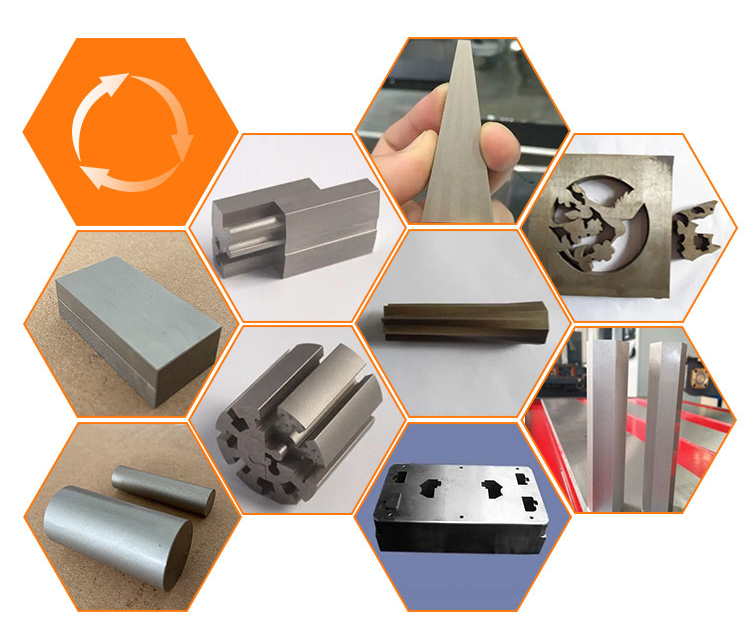

| brand: | Tongfang | Applicable industries: | Machining, parts processing, mold processing |

| Maximum cutting thickness: | 400mm | Marketing Type: | New Products 2022 |

| Showroom location: | not any | Machining Taper: | 6°/80mm |

| Warranty: | 1 year | CNC or not: | CNC |

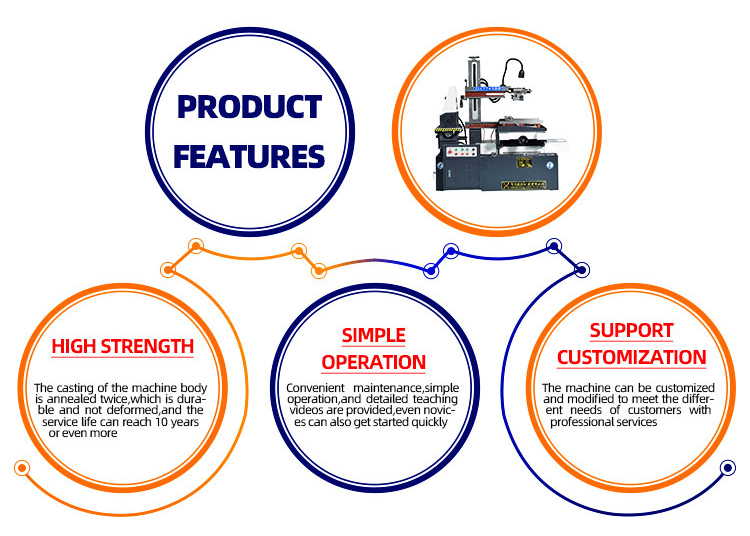

Taizhou Tongfang CNC has been focusing on the research and development of CNC wire cutting products for more than 20 years. The company produces a full range of DK77 CNC wire cutting machine tools, which use high-precision steel-inlaid V-type guide rails (linear guide rails are optional) and P3-level high-precision ball screws. The technology and quality are in the industry-leading position among similar products, with complete models, long service life and high precision. Machine specifications can be customized according to customer needs, non-standard models DK7740(45)J, DK7750(55)J, DK7763J, DK7780J, DK77100J, DK77120J and even larger models. The company also produces ±30°, ±45° swing large taper machine tools and CNC high-precision medium-speed wire cutting machine tools (accuracy ≤ ± 0.0025mm, roughness ≤ 0.8μm). The following are the main parameters of DK77 series machines:

1. Standard maximum cutting taper: ±6°/80mm; (optional ±15°, ±30°, ±45°)

2. Accuracy ≤0.015mm, in line with GB7926-2005 standard; (if equipped with linear guide rail, the accuracy can reach 0.01mm)

3. The best surface roughness is less than or equal to Ra2.5μm (single knife), Ra1.5μm (multiple knife);

4. Molybdenum wire diameter: 0.1-0.2mm;

5. Max. Cutting speed≥120mm²/min;

6. Voltage: three-phase 380V (single-phase 220V, three-phase 220V or other voltages can be customized), power: 3KW;

7. Working fluid: water-based emulsion (recommended DX-1 DX-4 Nanguang-1)

1. Standard maximum cutting taper: ±6°/80mm; (optional ±15°, ±30°, ±45°)

2. Accuracy ≤0.015mm, in line with GB7926-2005 standard; (if equipped with linear guide rail, the accuracy can reach 0.01mm)

3. The best surface roughness is less than or equal to Ra2.5μm (single knife), Ra1.5μm (multiple knife);

4. Molybdenum wire diameter: 0.1-0.2mm;

5. Max. Cutting speed≥120mm²/min;

6. Voltage: three-phase 380V (single-phase 220V, three-phase 220V or other voltages can be customized), power: 3KW;

7. Working fluid: water-based emulsion (recommended DX-1 DX-4 Nanguang-1)

Model | Table stroke (mm) | Table size (mm) | maximum. Cutting thickness(mm) | maximum. load (kg) | Dimensions (mm) | Weight (kg) |

DK7720 | 200*250 | 300*400 | 200 | 80 | 1000*900*1000 | 800 |

DK7725 | 200*320 | 320*510 | 300 | 120 | 1120*950*1240 | 1000 |

DK7735 | 350*450 | 360*630 | 400 | 300 | 1240*1170*1400 | 1200 |

DK7745 | 450*550 | 460*690 | 400 | 450 | 1600*1200*1400 | 1400 |

DK7755(50) | 550*630 | 550*900 | 600 | 700 | 1720*1680*1700 | 2000 |

DK7763 | 630*800 | 650*1040 | 600 | 1000 | 2100*1940*1780 | 2500 |

DK7745J | 450*630 | 460*840 | 400 | 500 | 1700*1600*1600 | 1800 |

DK7755J | 550*800 | 550*1040 | 600 | 750 | 2000*1900*1700 | 2300 |

DK7763J | 630*1000 | 650*1240 | 600 | 1100 | 2300*2200*1800 | 3000 |

DK7780 | 800*1000 | 890*1220 | 600 | 1200 | 3000*2400*1800 | 3500 |

DK7780J | 800*1200 | 890*1560 | 600 | 1500 | 3000*2400*1800 | 4500 |

DK77100 | 1000*1200 | 1060*1590 | 600 | 2000 | 3500*2800*2500 | 5500 |

DK77120J | 1200*1600 | 1230*1880 | 600 | 3200 | 3800*3000*2500 | 8000 |

Fully enclosed intelligent controller (one-way, one-cut)

* Standard system: X8 (support multi-language switching)

* Optional system: AutoCut, HL, HF

* Standard system: X8 (support multi-language switching)

* Optional system: AutoCut, HL, HF

* Parameter adjustment reference table, convenient for operators to set processing parameters

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Reverse processing of short-circuit automatic retraction program with touch dust-proof button

* Mirror cut, also available for any angle and circular rotation

* Can store 4999 wire cutting control instructions at a time

* Automatic shutdown after processing

* With digital display function power-off protection

* Totally enclosed, anti-fouling, dust-proof

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Reverse processing of short-circuit automatic retraction program with touch dust-proof button

* Mirror cut, also available for any angle and circular rotation

* Can store 4999 wire cutting control instructions at a time

* Automatic shutdown after processing

* With digital display function power-off protection

* Totally enclosed, anti-fouling, dust-proof

optional controller

* Standard system: AutoCut with AutoCAD

* Optional system: X8,HF

Vertical high-speed intelligent controller (one-way, one-cut)

* Standard system: AutoCut with AutoCAD

* Optional system: X8,HF

* Parameter adjustment reference table, convenient for operators to set processing parameters

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Adopt touch dustproof button

* Integration of programming and control; synchronous programming of processing, real-time tracking and display of processing trajectory; 3D modeling

* CAD/CAM data exchange operations for up and down special-shaped, equal radius, right-angle transition taper processing

* International standard ISO code control

* Totally enclosed, dust-proof, anti-fouling

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Adopt touch dustproof button

* Integration of programming and control; synchronous programming of processing, real-time tracking and display of processing trajectory; 3D modeling

* CAD/CAM data exchange operations for up and down special-shaped, equal radius, right-angle transition taper processing

* International standard ISO code control

* Totally enclosed, dust-proof, anti-fouling

Fully intelligent multi-pass (multi-cut) controller

* Standard system: AutoCut with AutoCAD

* Support two processing modes: normal fast wire feeding mode and medium wire feeding multi-cut processing mode

* Standard system: AutoCut with AutoCAD

* Support two processing modes: normal fast wire feeding mode and medium wire feeding multi-cut processing mode

* With cutting speed adaptive control

* The cutting process is displayed in real time, and the processing preview is convenient

* Real-time monitoring of the machining status of X, Y, U, V four axes of the machine tool

* Has a user-maintainable process library that makes multiple runs simple and reliable

* The cutting process is displayed in real time, and the processing preview is convenient

* Real-time monitoring of the machining status of X, Y, U, V four axes of the machine tool

* Has a user-maintainable process library that makes multiple runs simple and reliable

VIEW MORE

YOU MAY LIKE