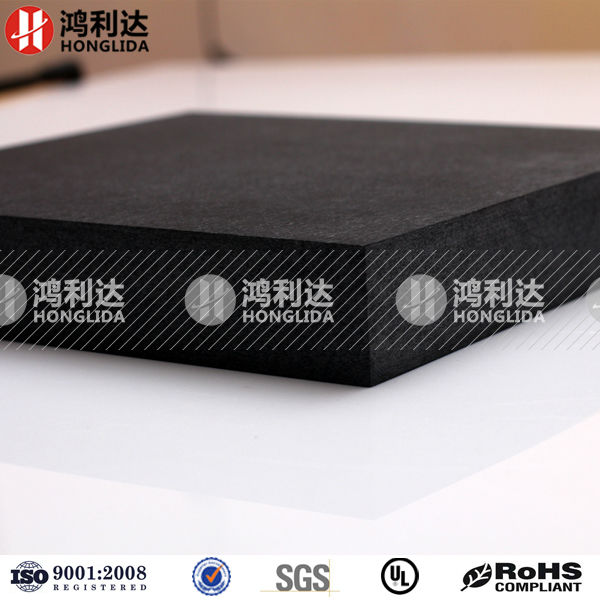

Black fiberglass anti-static board epoxy resin composite board is used for test fixture

- $10.00 / >=600 kilograms

- 600 kilograms

- Jiujiang Honglida Composite Material Manufacture Co., Ltd.

- Jiangxi, China

- Mr Leon Zhu

| Rated voltage: | 200V | type: | insulation sheet |

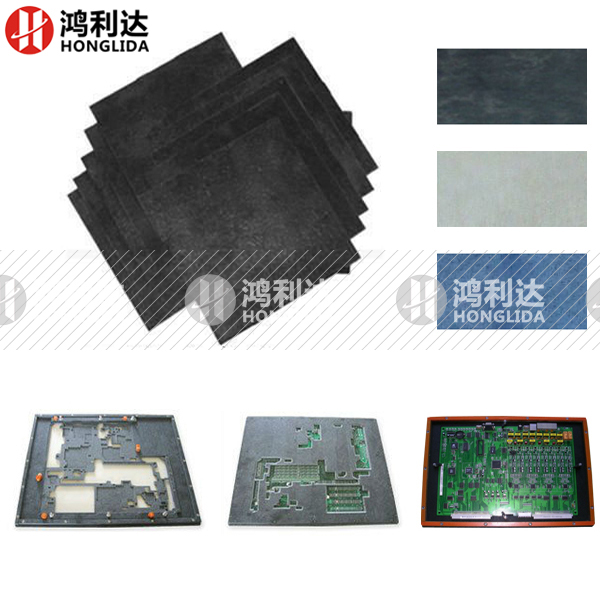

| Certification: | RoHS, SGS, ISO9001:2008 | thickness: | 3-150mm |

| Material: | epoxy resin, fiberglass mat | Operating temperature: | 300℃ |

| sample: | provide sample | Selection of color: | black, blue, gray |

| tensile strength: | 400MPa | Typical dimensions: | 1220x2440mm, 1020x1220mm, 1160x1260mm |

| model: | HLD-H001 | Origin: | Jiangxi, China |

| brand: | HDL | Maximum welding: | 330°C |

| payment terms: | L/C, T/T | application: | Wave soldering tray/reflow soldering fixture/test fixture, high temperature |

| density: | 1.95 g/cm3 | product name: | Black fiberglass anti-static board |

| Packaging Details: | Black Fiberglass ESD Board Epoxy Composite Boards for Test Fixtures are packaged in wooden pallets with plastic film wrap and paper protective corners. Custom cut sizes are acceptable. | Supply capacity: | 50 metric tons of black fiberglass ESD sheets per week |

| port: | Ningbo, Shanghai, Jiujiang |

Black fiberglass anti-static board epoxy resin composite board is used for test fixture

Black Fiberglass Anti-static Sheet Epoxy Resin Composite Panel Test Fixture is a fiber reinforced plastic composite material composed of fiberglass mat and high mechanical resin material. It is widely used in the PCB (Printed Circuit Board) manufacturing industry for wave soldering trays, reflow soldering fixtures, and test fixtures. It has extremely high mechanical strength, high temperature resistance, ESD antistatic performance and good chemical resistance. There are flakes, common thickness: 4mm, 5mm, 6mm, 8mm, 10mm, 12mm (other thicknesses are optional), the most common size is 1220x2440mm, 1020x1220mm, 1160x1260mm. Natural colors are black, blue and gray.

number | Test items | unit | Require | Test Results | Test Methods |

1 | Bending Strength (Normal) | MPa | — | 393 | GB/T9341-2008 |

2 | Flexural Modulus of Elasticity (Normal) | MPa | — | 2.20x104 | |

3 | Surface resistivity | ohm | — | 2.0x107 | GB/T1410-2006 |

4 | Charpy impact strength (unnotched) | kJ/square meter | — | 95.2 | GB/T1043.1-2008 |

5 | Transient Temperature (350°C, 20s) - Appearance | — | — | Keep the change, please | vision test |

6 | Working Temperature(280°C, 3000min) - Appearance | — | — | No change, a bit lighter in color | |

7 | transverse shear strength | MPa | — | 60.9 | GB/T 5130-1997 |

8 | density | g/cubic centimeter | — | 1.95 | GB/T 1033.1-2008 Method A |

9 | moisture | % | — | 0.08 | GB/T 1034-2008 Method 1 |

10 | Linear expansion (30°C—200°C) | 10-6/kg | — | 6.996 | National Standard/T 1036-2008 |

11 | Thermal conductivity (40°C) | Width/(m·K) | — | 0.614 | GB/T10295-2008 |