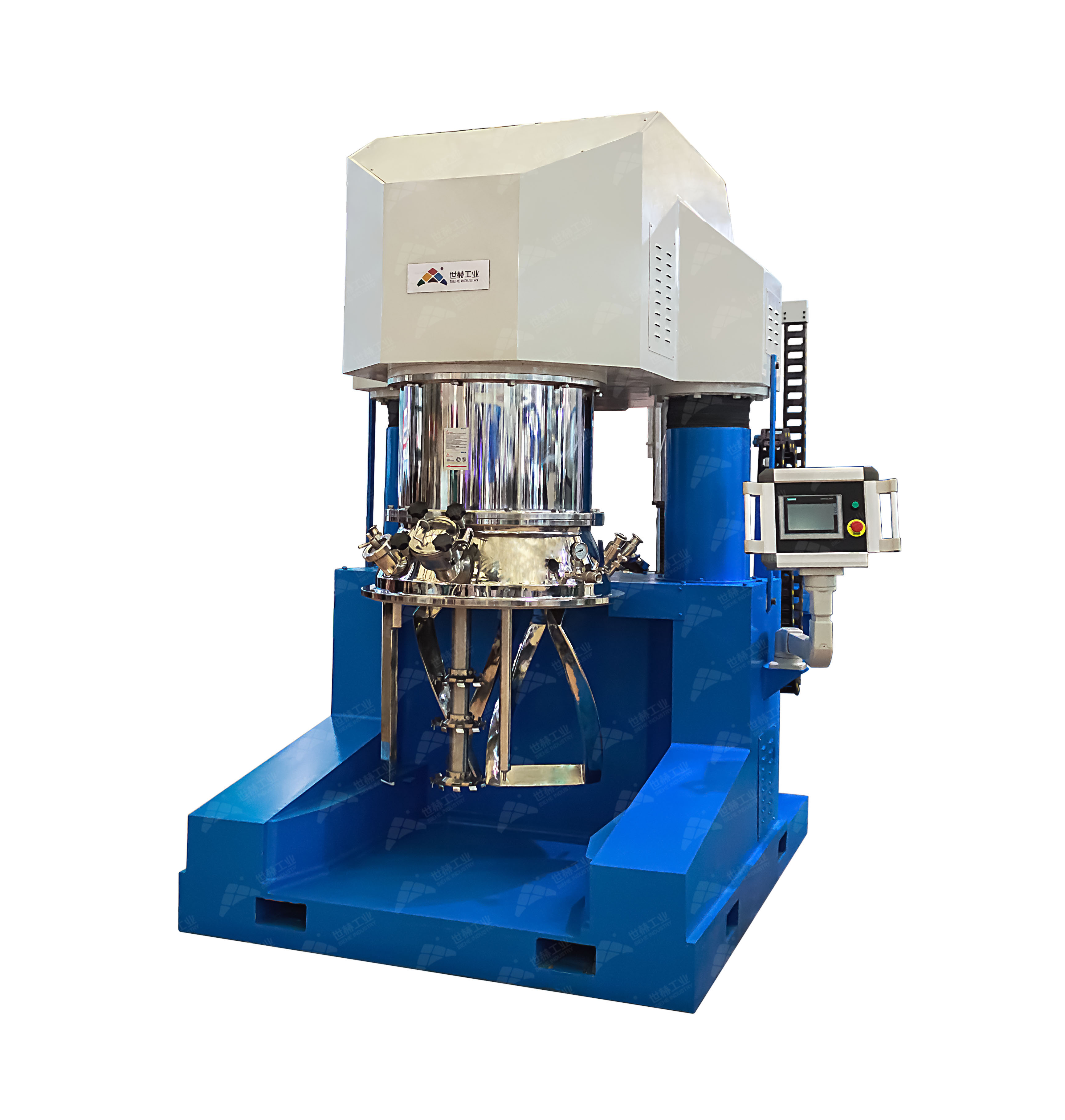

Chemical liquid alkyd resin reactor tank complete production line

- $10000.00 /set

- 1 set

- Shanghai Siehe Import & Export Co., Ltd.

- Shanghai, China

- Ms Susan Yang

| After-sales Service Provided: | Field installation, commissioning and training,Video technical support,Online support; | Vacuum: | Optional; |

| Package Preview: | ; | Supply Ability: | 10 Sets per Quarter; |

| Material: | SS304/SS316L; | Condition: | New; |

| Payment Terms: | L/C,D/P,T/T; | Warranty: | 1 Year; |

| Voltage: | 220-480V; | Type: | Reaction Kettle; |

| Power: | Customized; | Certification: | ISO, TUV; |

| Automatic Grade: | Automatic; | Brand Name: | SIEHE resin line; |

| Dimension(L*W*H): | Depends on capacity; | Feeding: | Manual / mechanical; |

| Port: | Shanghai port; | Packaging Detail: | LCL: wooden case packaged with steel frame; FCL: well fixed and naked in the container; By sea/railway/air; |

| Heating/cooling: | Oil/water/ steam; | Applicable Industries: | Manufacturing Plant; |

| Weight: | Depends; | Place of Origin: | Shanghai, China; |

| Discharging: | Pump; |

Application

Resin production line

------for producing resins and emulsions

consists of: batching kettle(droplet add kettle), reactor, vertical distillation column, vertical condenser, horizontal condenser, water knockout drum, overflow tank, pipelines, attenuation harmony kettle, filling machine, etc main devices equipped with heating device(hot oil/steam boiler), cooling system(refrigerating machine/cooling tower), vacuum system, etc.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

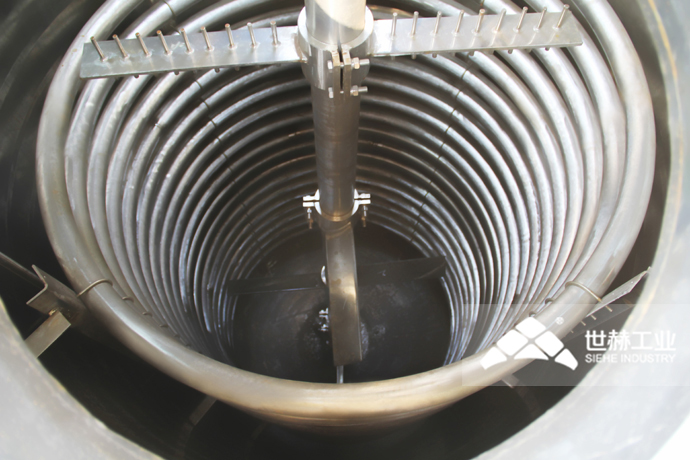

Mixing agitator of reactor

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

| Power (kW) | Speed (rpm) | Tank size (dia.*h) (mm) | Capacity (L) | ||

Pre-sales service

1. Muti-language consult, English, Chinese, Russia, etc.

2. Suitable, reasonable technical advise and solutions;

3. Lab room with experiments and instruments for test service to obtain data and production experience;

4. Phone: 0086-021-52913185

Skype: siehe.sales09

On-sales service

1. Project-Manager system: one customer, one project manager.

2. Schematic drawing for core equipments;

3. Production process follow-up;

4. Factory visit for equipment test before delivery;

5. Technical documents for equipments, such as English version operational manual, drawing of circuit, etc.

After-sales service

1. One year warranty;

2. 7×24h service line;

3. Overseas engineering service team for installation and training at your site;

4. Abundant warehouse of spare parts purchasing;

5. Equipment update service;

6. Detailed records of communications;

Q 1: Payment terms capacity?

A 1: L/C, T/T, D/P, cash, Alibaba trade assurance;

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIP, CIF and DDU;

Q 3: Validity of quotation?

A 3: Within 30 days;

Q 4: Modes of shipment?

A 4: By sea, by railway, by air and by express;

Q 5: Warranty?

A 5: One year and lifelong service provided at cost;

Q 6: Installation and training?

A 6: usu. tel or mail guidance for installation, for production line, paid overseas engineering service provided.

Butterfly mixer

Disperser

Planetary mixer