Styrene Polyvinyl Acetate Acrylic Copolymer/Epoxy Resin Reactor Production Line

- $1700.00 /set

- 1 set

- Laizhou New Hongda Chemical Machinery Co., Ltd.

- Shandong, China

- Mr CHUNLEI YU

| type: | tower reactor | Material: | SS304/SS316L/carbon steel |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Supply capacity: | 30 sets of styrene acrylic copolymer and polyvinyl acetate production lines per month/ |

| Mechanical test report: | if | Automatic level: | automatic |

| Local service locations: | not any | Hybrid type: | blender |

| heating: | electric heating/steam heating | Main selling points: | long lasting |

| Origin: | Shandong Province, China | Seal type: | Mechanical seal/packing seal |

| Video outbound inspection: | if | port: | Qingdao |

| Voltage: | 220V/380V | Packaging Details: | Standard export plywood case for styrene acrylic copolymer and polyvinyl acetate production line/epoxy resin reactor equipment, or according to customer's requirements. |

| Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, household, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies | color: | custom made |

| After Warranty Service: | Video technical support, online support | Marketing Type: | 2020 New Products |

| product name: | Styrene Acrylic Copolymer Production Line/Epoxy Resin Reactor | MOQ: | 1 set |

| Certification: | CE/ISO9002 | Warranty: | 1 year, 1 year |

| Core component warranty: | 1 year | Health status: | new |

| After-sales service provided: | Video technical support, online support | Package preview: | |

| Showroom location: | not any | capacity: | 50-28000L |

| Key words: | Acrylic Styrene Reactor | strength: | 1.1-15KW |

| application: | UPR, alkyd resin, phenolic resin, epoxy resin, ABS resin, paint | brand: | New HTC |

| weight: | custom made | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Dimensions (L*W*H): | custom made |

product information

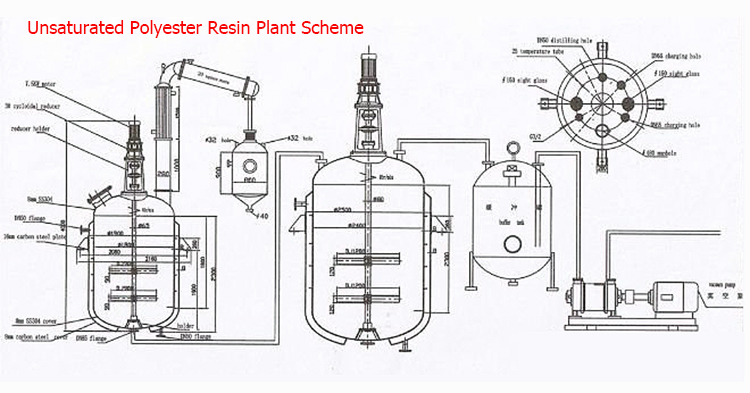

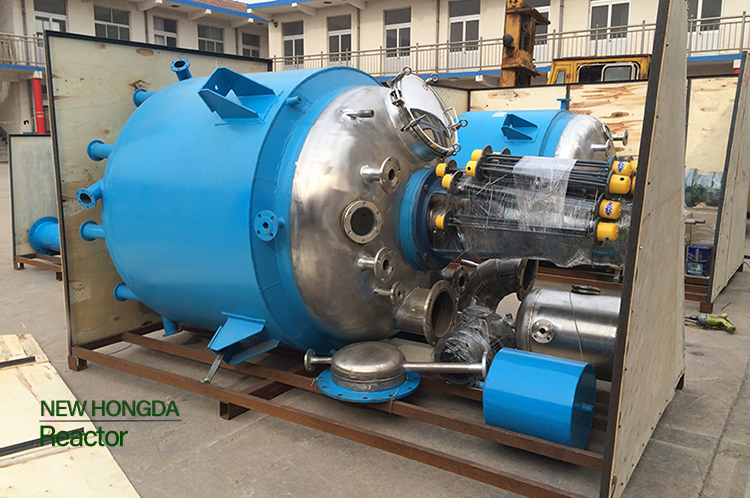

Styrene Acrylic Copolymer and Polyvinyl Acetate Production Line/Epoxy Resin ReactorFor unsaturated polyester, phenolic resin, epoxy resin, ABS, paint

Details

- Volume: 50-10000L

- Material: SS304, SS316L, carbon steel

- Applications: Petroleum, rubber, dye, medicine, food, resin, paint, paint, adhesive, pigment, pesticide, silicone oil, ink, glue, white latex, etc.

- Sealing form: mechanical seal or stuffing seal

- Agitator Type: Anchor, Frame, Paddle, Impeller, Vortex, Propeller, Turbine, Push or Stand

- Heating method: electricity, steam or external coil.

Reactor technical data

|

detailed image

Condenser Data

| Reactor (large) | Packing volume (cubic meter) | Vertical cooling area (m²) | Horizontal cooling area (m²) | Water storage tank (L) |

| 50 | 0.002 | 0.1 | 0.29 | 8 |

| 100 | 0.005 | 0.19 | 0.58 | 30 |

| 300 | 0.01 | 0.22 | 1.49 | 53 |

| 500 | 0.015 | 0.38 | 2.08 | 70 |

| 1000 | 0.025 | 0.62 | 3.17 | 140 |

| 2000 | 0.042 | 1.06 | 5 | 245 |

| 3000 | 0.063 | 1.52 | 10 | Chapter 346 |

| 4000 | 0.086 | 1.86 | 15 | 400 |

| 5000 | 0.096 | 2.07 | 20 | 500 |

Tube Condenser Data

| Specifications (square meters) | 0.3 | 0.6 | 1.0 | 1.5 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 15 | |

| Effective length (mm) | 550 | 600 | 1000 | 1000 | 1400 | 1500 | 1500 | 1600 | 1800 | 2000 | 2200 | 2100 | 2100 |

| Outer diameter (mm) | 150 | 180 | 180 | 210 | 220 | 270 | 270 | 300 | 300 | 350 | 400 | 500 | 500 |

Technology

application

Packaging Information

Standard strong export plywood case, equipment pallet, or as per customer's requirement.

Delivery Information

About shipping method

A: By sea or by air, the detailed delivery method can be discussed.

About delivery time

A: Usually it will take about 15-30 working days after we receive your advance payment for purchase order. However, it depends on the complexity of our production plan and equipment.

About Incoterms

A: Usually we send the equipment in FOB term, however, CIF is also acceptable, it can be decided by customers.

Payment Information

By T/T in advance or irrevocable L/C at sight. The transaction will be guaranteed by Alibaba.

The equipment can be customized, welcome to consult us for more detailed price, packaging and delivery information.

Company Profile

In 1996, Wang Zhongren founded Xinhongda Chemical Machinery Co., Ltd. in Laizhou, which is located on the coast of Laizhou Sea. Xinhongda is committed to providing solutions for mechanical product customers, so as to achieve excellent productivity and return on investment.

In the past 20 years, Xinhongda Corporation has developed from a regional marketer of chemical machinery and equipment in China to a manufacturer of complete product varieties/series and services with global competitiveness, providing life cycle solutions to maximize customer return on investment. The main products are resin complete production line, paint coating complete production line, BMC/SMC complete production line, adhesive complete production line, dry powder mortar production line, reaction kettle of various specifications and models, disperser, grinder, mixer, kneader, filter, emulsification machines and other complete sets of equipment. These products serve a wide range of industries including cosmetics, metallurgy, food processing, pharmaceutical, feed, paper, paint, resin, construction, fertilizer and chemical industries.

We can customize reactors of different specifications according to customer requirements. There are more than 10 series of product catalogs and engineers to help you, welcome to consult us for more details.

Project case

certified

Our complete product quality control system has passed ISO9002 and CE certification.

our service

1. What is your advantage?

a. Delivery on time.

b. More than 20 years experience.

c. The quality is guaranteed and the service is professional.

d.OEM and ODM. Various designs are made according to customer's requirements.

2. How to place an order?

Send inquiry→basic quotation→confirm details→PI and contact information→pay deposit→production (20-30 days)→pay the balance→delivery (5-8 days by air, 28-35 days by sea.)→after-sales service .

3. Will you send us the drawings of the required machines for checking?

Yes, we would like to send you a sketch of the desired machine. After you place an order, we will send you detailed drawings

and technical parameters. After confirming the production, it can be put into production.

4. Is there any quality assurance and after-sales service?

The warranty period of the mechanical part of the equipment is one year after you receive the equipment, and help the buyer to install and debug the equipment, and train the operators for free.

For more product details, please click here to enter