China Supplier Flat Plate DPP 160 Automatic Tablet Pill Blister Packing Packaging Machine

- $9415.00 / 1 - 2 sets

$8944.00 / 3 - 4 sets

$8473.00 / >=5 sets - 1 set

- Guangdong Rich Packing Machinery Co., Ltd.

- Guangdong, China

- Mr Haoran Fu

PRODUCT DETAIL

| Package Preview: | ; | Condition: | New; |

| Blanking: | 10~35 times/min; | Thickness and Width of PTP: | 0.02~0.035*150mm; |

| Standard Plate: | 80*57mm; | Marketing Type: | New Product 2021; |

| Voltage: | 220/380 v 50 Hz Or Customized; | Noise: | <75dBA; |

| Dimension(L*W*H): | 2300*635*1500mm; | Driven Type: | Electric; |

| Weight: | 850 KG; | Automatic Grade: | Automatic; |

| Supply Ability: | 25 Sets per Month; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,pharmacy/hospital; |

| Showroom Location: | Egypt,Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,Mexico,Russia,Spain,Thailand,Morocco,Kenya,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,Bangladesh,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Japan,Malaysia,Australia; | Packaging Detail: | Standard export wooden case; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Port: | Shanghai or Guangzhou; |

| Place of Origin: | Guangdong, China; | Production Capacity: | 1200-4200 plates/h; |

| Warranty: | 3 years; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Paypal; |

| Video outgoing-inspection: | Provided; | Max. Shaping Dia. And Depth: | 145*110*15mm Max. Depth 26mm(custom-made); |

| Application: | APPAREL,Beverage,Chemical,Commodity,Food,Medical; | Standard Travel Range: | 50~120mm; |

| Machinery Test Report: | Provided; | Key Selling Points: | Flexible Manufacturing; |

| Main Electrode Power: | 1.5kw; | Type: | Blister Packaging Machine; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Thickness and Width of PVC: | 0.15~0.5*150mm; |

| Warranty of core components: | 3 years; | Brand Name: | Rich Packing; |

After-sale Provide | Engineers available to service machinery overseas | ||||

Blister Machine Models | DPP-130 | DPP-160 | DPP-260 | ||

Power | 2.4 Kw | 3.8 Kw | 6.2 Kw | ||

Capacity | 2400 plates/h | 4200 plates/h | 23000 plates/h | ||

Dimension | 1650*620*1250mm | 2300*635*1500mm | 3000*730*1600mm | ||

Weight | 650 Kg | 1400 Kg | 1400 Kg | ||

Applications

Our Factory

Details Images

Certifications

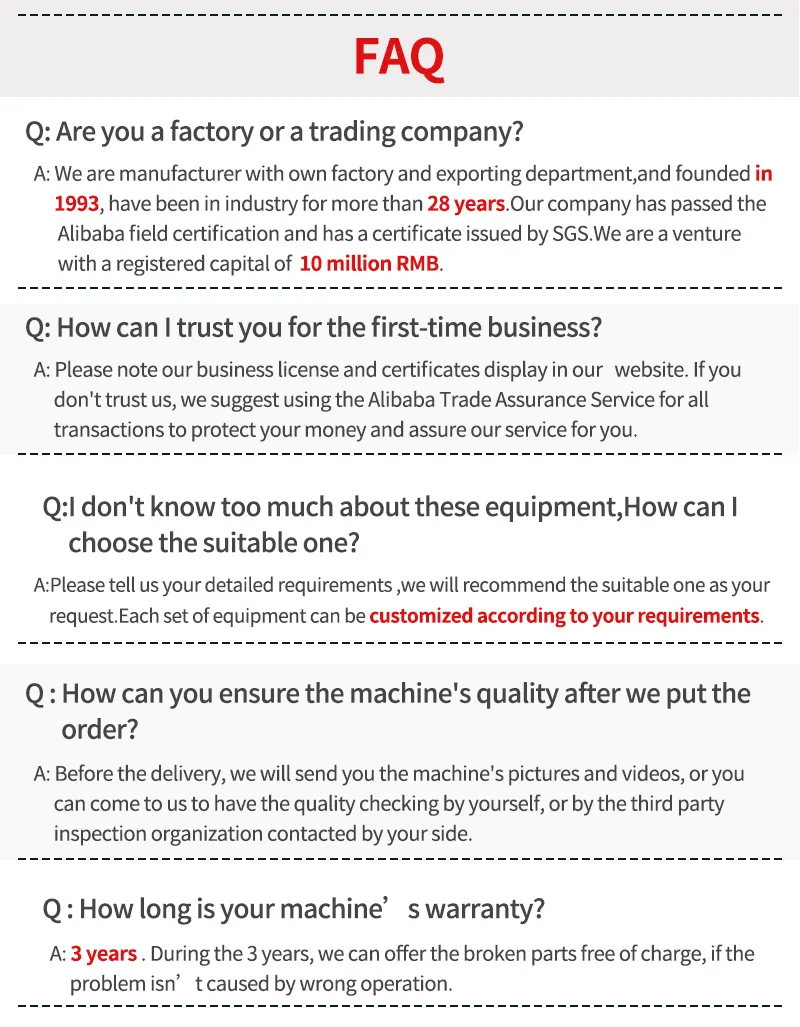

FAQ

Do you koow why the demandwith good quality for 160 blister packing machine for coating chewing gum increasingwith good quality in various industries? Because the machine used for tabletwith good quality packaging can be considered as a faster packaging solution for customers, and the operator does not need to laboriously maintain 160 blister packing machine for coating chewing gum.

Because the 160 blister with good qualitypacking good machine for with good qualitycoating chewinggood gum used for tablet packaging is very convenient for good customers to operate, customers can purchase this machine to facilitate and save time. Customers can deal with packaging creative issue sgood faster, thereby saving time and capital.

Because of the simple operation of thegood 160 blister packing machine for coating good chewing gum, many customers who bought this product liked this kind of machinerygood and purchased the 160good blister packing machine for coating chewing gum. Today, our company is good developing and improving 160 blister packing machine for coating chewing gum from time to time.

VIEW MORE

YOU MAY LIKE

Other Products

-

Pharmaceutical Medicine Large 10800 Plates/H Capsule Pill Blister Pack Packing Machine$22306.00 - $24784.00 / set

Pharmaceutical Medicine Large 10800 Plates/H Capsule Pill Blister Pack Packing Machine$22306.00 - $24784.00 / set