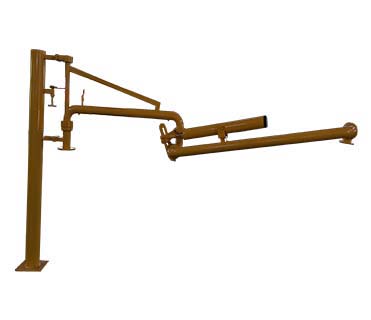

Fuel Oil Refined Diesel Aluminum Top And Bottom Truck Liquid Loading Arm For Movable Top Loading Skid-Mounted System

- $870.00 /piece

- 1 piece

- Henan Station Energy Technology Co., Ltd.

- Henan, China

- Ms Lara Miller

PRODUCT DETAIL

| Size: | customers' Requirment; | Brand Name: | Station; |

| Transport Package: | Pallet or Plywood Case; | Showroom Location: | None; |

| Packaging Detail: | carton; | Package Preview: | ; |

| Spare Parts Type: | Not avaible; | Local Service Location: | None; |

| Machinery Test Report: | Not Available; | Port: | QINGDAO/SHANGHAI; |

| Marketing Type: | New Product 2020; | After-sales Service Provided: | Free spare parts; |

| Material: | Stainless steel/Carbon steel; | Execution standard: | HG/T21608-2012; |

| Warranty: | 6 Months; | Product name: | Top oil depot marine loading arm for sale; |

| Key Selling Points: | easy to handle; | Supply Ability: | 3500 Sets per Month; |

| Place of Origin: | Henan, China; | Applicable Industries: | Energy & Mining; |

| Condition: | New; | Video outgoing-inspection: | Not Available; |

| Payment Terms: | Western Union,T/T; | Role: | transfer fluid medium; |

| HS Code: | 8428909090; | Nominal diameter: | DN50/DN80/DN100; |

| After Warranty Service: | Video technical support; | Model Number: | ST1402; |

Products Description

1.The product is an arm-type facility which connects the steel pipelines and elbows with rotary joints to realize the connection between train /car tanker and pipeline of storage and transportation. It replaces the old hose connection and has reliable safety and flexibility.

2. The key parts of loading/unloading arms in our company use alloy steel and stainless steel. These arms are processed by precise CNC machine tools,with built-in double raceway supporting structure. They rotate flexible and reliable.

3. The sealing ring has unique structure and is made of reinforced PTFE material. Its sealing surface is polished and wear

resistance is great.sealing performance is superior and reliable. Therefor,our company's loading arm is well sealed and has a long service life.

4. Reasonable spring steel balance system makes the operation of contraposition lightweight and convenient

5.All the main pressure-bearing pipes are welded by argon-arc welding.

6.The loading arms for flammable and explosive medium are Equipped of electrostatic grounding system of high quality and reasonable design.The electrostatic resistance is less than 2Ω and the safety performance is reliable.

7. The structure of arm is reasonable and with the minimum size as possible to achieve the maximum coverage area as possible.

8. Using high-quality paint, strict and reasonable painting process, twice epoxy zinc-rich primer, twice chlorinated rubber

top-coat. Total paint film thickness is more than 100 um. And strict control of each process of spraying paint to ensure the high quality of surface paint, can well achieve the requirements of corrosion protection.

2. The key parts of loading/unloading arms in our company use alloy steel and stainless steel. These arms are processed by precise CNC machine tools,with built-in double raceway supporting structure. They rotate flexible and reliable.

3. The sealing ring has unique structure and is made of reinforced PTFE material. Its sealing surface is polished and wear

resistance is great.sealing performance is superior and reliable. Therefor,our company's loading arm is well sealed and has a long service life.

4. Reasonable spring steel balance system makes the operation of contraposition lightweight and convenient

5.All the main pressure-bearing pipes are welded by argon-arc welding.

6.The loading arms for flammable and explosive medium are Equipped of electrostatic grounding system of high quality and reasonable design.The electrostatic resistance is less than 2Ω and the safety performance is reliable.

7. The structure of arm is reasonable and with the minimum size as possible to achieve the maximum coverage area as possible.

8. Using high-quality paint, strict and reasonable painting process, twice epoxy zinc-rich primer, twice chlorinated rubber

top-coat. Total paint film thickness is more than 100 um. And strict control of each process of spraying paint to ensure the high quality of surface paint, can well achieve the requirements of corrosion protection.

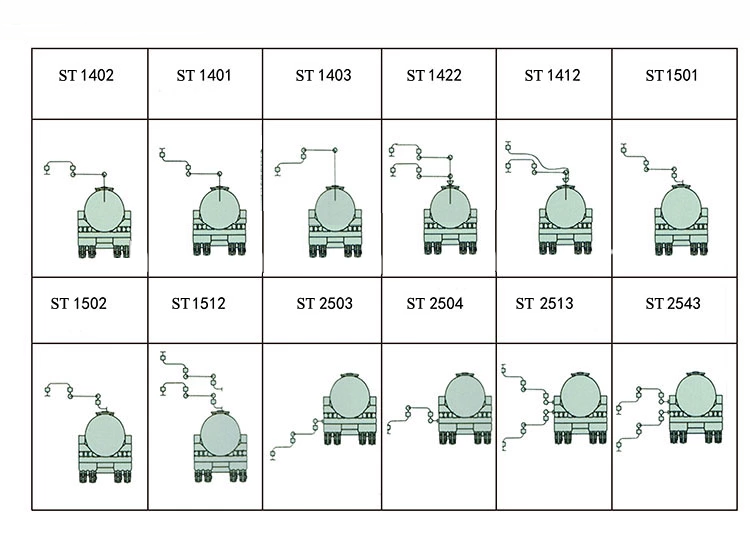

Other products

Packing & Delivery

The key parts of loading/unloading arms in our company use alloy steel and stainless steel. All the inner rings of carbon steel rotating joint are made of 304 stainless steel. Outer rings are made of 45# forgings ,with built-in double raceway supporting structure. They rotate flexible and reliable.

The whole loading arm is treated by shot blasting and sand blasting,which change the appearance or shape of the workpiece's outer surface.Because of the impact and cutting action of abrasives on the workpiece surface,the surface of the workpiece can obtain a certain degree of cleanliness and different roughness, and some impurities such as rust and oxide scale can be removed ,so as to improve the mechanical properties of the workpiece surface ,so the fatigue resistance of the workpiece is improved, the adhesion between the workpiece and the coating is increased, and the durability of the coating is prolonged.

Special paint for Huaxin loading arm :Epoxy zinc-rich primer,chlorinated rubber top-coat.The content of zinc powder is over 90% in epoxy zinc-rich primer.Due to the high content of zinc powder in the coating, the zinc powder particles can be in close contact with the coated steel surface, which plays an cathodic protection of electrochemistry .

Certifications

VIEW MORE

YOU MAY LIKE