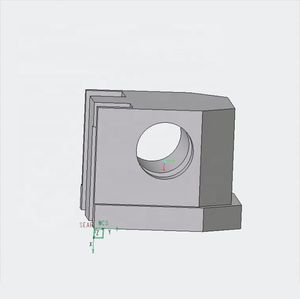

Full Auto Mobile Metal Aluminum POM Sear Switch Plastic Selector

- $2.10 /piece

- 1 piece

- Shenzhen Seasons Cross Technology Co., Ltd.

- Guangdong, China

- Ms Doris Y

PRODUCT DETAIL

| Brand Name: | SEANSONSCROSS; | Quality control: | 100% Inspection; |

| Tolerance: | +/- 0.01mm;±0.05mm; | Product Keywords: | Full plastic auto selector; |

| Micro Machining or Not: | Micro Machining; | Price: | Factory direct sale; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Model Number: | 005; |

| Process: | Cnc Turning; | CNC Machining or Not: | Cnc Machining; |

| Surface treatment: | Polishing,painting,coating.etc.; | Place of Origin: | Guangdong, China; |

| Packaging Detail: | Poly bag+ Master carton box;; | Package Preview: | ; |

| Color: | Natural or customized; | type: | Precision parts; |

| Material: | Plastic, Stainless Steel Alloy: 17-4PH, 304L ,316L , 420J2, 440C.etc.; | Material Capabilities: | Aluminum,Brass,Bronze,Copper,Hardened Metals,Precious Metals,Stainless Steel,Steel Alloys; |

| Supply Ability: | 50000 Pieces per Month; | Port: | shenzhen; |

| Shape: | As your design; | Type: | Broaching,DRILLING,Etching / Chemical Machining,Laser Machining,Milling,Other Machining Services,Turning,Wire EDM,Rapid Prototyping; |

Product Presentation

Full Auto Mobile Metal Aluminum POM Sear Switch Plastic Selector

High Precision CNC Machining Metal Injection Molding Components Stainless Steel Plastic Parts | |

Material 1. | Stainless Steel Alloy: 17-4PH, 304L ,316L , 420J2, 440C.etc. |

Material 2. | Aluminum: 5052/6061/7075 |

Material 3. | Brass |

Material 4. | POM,Plastic,Carbon Steel |

Drawing | STEP, IGS, PDF, etc. |

Surface treatment | Anodized, polished,as per request. |

Company Introduction

Certifications

Packaging: PET + FOAM + Paper/Plywood Box

Shipping

FAQ

Q: What's MIM process?

A: MIM (Metal Injection Molding) is a manufacturing technology that combines the shape making complexity of Plastic Injection Molding with the material flexibility of Powder Metallurgy.

Q: What's the Characteristics of MIM?

A: As a near net forming technology for manufacturing high quality precision parts, MIM has the advantages of conventional and machining methods. MIM can make a lot of complex shape parts: such as various external cutting, thread, conical outer surface, surface knurling and so on, has more features of the parts are not to use conventional powder metallurgy method. Due to the MIMmanufacturing parts almost do not need to be machined, so reducing the material consumption, the number of complex shape parts in production requirements is higher than a certain value, MIM will be more economical than machining method.

Q: Why should I choose MIM?

A: MIM excels in producing small, highly complex parts that are difficult or cost prohibitive to produce with conventional

technologies such as machining or casting.

Q: How do I place order?

A: First, Please help to send us the product drawing, then We will check the drawing and the price will be quoted for you within 2 workhours.

Q: Which port is the nearest from you?

Shenzhen

Any question, feel free to contact us!

Welcome to visit our factory!

A: MIM (Metal Injection Molding) is a manufacturing technology that combines the shape making complexity of Plastic Injection Molding with the material flexibility of Powder Metallurgy.

Q: What's the Characteristics of MIM?

A: As a near net forming technology for manufacturing high quality precision parts, MIM has the advantages of conventional and machining methods. MIM can make a lot of complex shape parts: such as various external cutting, thread, conical outer surface, surface knurling and so on, has more features of the parts are not to use conventional powder metallurgy method. Due to the MIMmanufacturing parts almost do not need to be machined, so reducing the material consumption, the number of complex shape parts in production requirements is higher than a certain value, MIM will be more economical than machining method.

Q: Why should I choose MIM?

A: MIM excels in producing small, highly complex parts that are difficult or cost prohibitive to produce with conventional

technologies such as machining or casting.

Q: How do I place order?

A: First, Please help to send us the product drawing, then We will check the drawing and the price will be quoted for you within 2 workhours.

Q: Which port is the nearest from you?

Shenzhen

Any question, feel free to contact us!

Welcome to visit our factory!

VIEW MORE