Personalized MIM Stainless Steel 303/304 Bipolar Forceps Medical Instrument for Open Surgery

- $0.25 / >=1000 pieces

- 1000 pieces

- Shenzhen Seasons Cross Technology Co., Ltd.

- Guangdong, China

- Ms Doris Y

| Iron-nickel alloy: | Fe-8%Ni | Marketing Type: | New Products 2020 |

| Supply capacity: | 90,000 pieces per month | Local service location: | not any |

| Surface treatment: | Polishing, painting, coating, etc. | type: | Precision parts |

| process: | Strong compaction - sintering - machining | accurate: | 0-0.01mm; ±0.05mm |

| Weight (kg): | 0.3kg | Applicable industries: | Energy and Mining, Medical Devices |

| type: | powder metallurgy | Material: | Plastic/Brass/Carbon Steel/Aluminum/Stainless Steel |

| plating: | custom made | Product Keywords: | open surgical bipolar forceps |

| place of origin; place of origin: | Guangdong, China | Mechanical test report: | if |

| shape: | as your design | port: | Shenzhen |

| Main selling point: | accurate | brand: | cross season |

| Packaging Details: | Plastic bag + main carton; | Spare Parts Type: | all available |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Health status: | new |

| price: | Factory direct sales | color: | natural or custom |

| Material: | Stainless steel | Warranty: | 6 months |

| Video external inspection: | if | Showroom location: | not any |

Customized MIM Stainless Steel 303/304 Medical Parts Instrument Open Surgery Bipolar Forceps

|

Material: |

Plastic/Brass/Carbon Steel/Aluminum/Stainless Steel: 17-4PH, 304L , 316L , 420J2, 440C. ETC. |

|

Finish: |

Polished or as your request. |

|

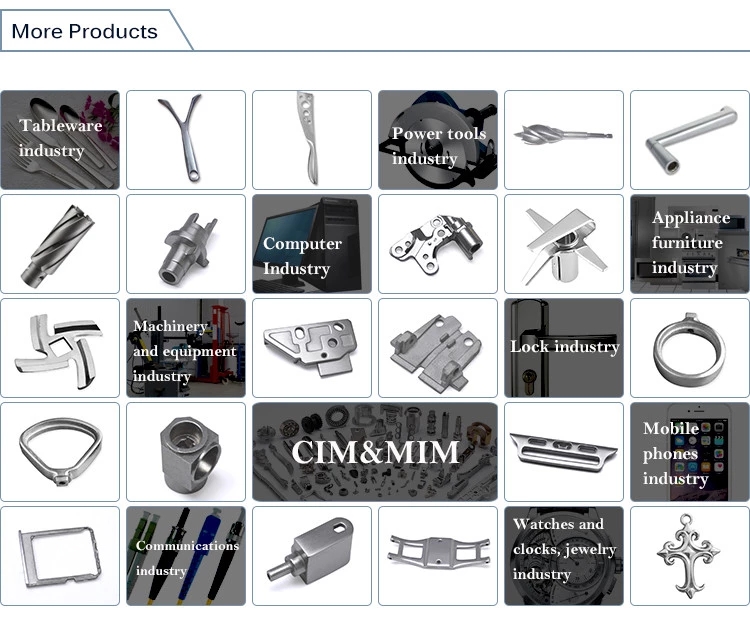

application: |

Precision instruments, medical equipment, camera accessories, fishing gear accessories, auto accessories, mobile phone accessories, pneumatic tools.etc. |

|

Processing: |

Mixing, pelletizing, injection, degumming, sintering, CNC columnprocess. |

|

Pay: |

50% deposit, 50% T/T before delivery |

Host parts pictures:

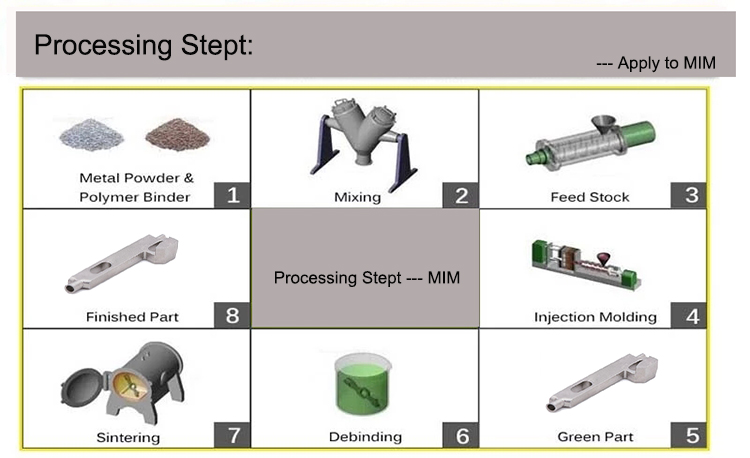

Processing:

machine:

more:

FAQ:

Q: What is the MIM process?

A: MIM (Metal Injection Molding) is a manufacturing technique that combines the shape-making complexity of plastic injection molding with the material flexibility of powder metallurgy.

Q: What are the characteristics of MIM?

A: As a near-net-shape technology for manufacturing high-quality precision parts, MIM has the advantages of conventional and machining methods. MIM can manufacture many parts with complex shapes: such as various external cuts, threads, conical outer surfaces, surface knurling, etc., and has more parts features that cannot be used with conventional powder metallurgy methods. Since the parts produced by MIM require almost no machining, the material consumption is reduced, and the number of complex-shaped parts in production is required to be higher than a certain value, MIM will be more economical than the machining method.

Q: Why should I choose MIM?

A: MIM excels at producing small, highly complex parts that are difficult or prohibitively expensive to produce using traditional methods

Techniques such as machining or casting.

Q: How do I place an order?

A: First, please help to send the product drawings to us, then we will check the drawings and quote you within 2 working hours.

ask:Which port is closest to you?

Shenzhen

touch: