Fully automatic pure water machine pouch filling and sealing machine open small water plant

- $1800.00 / 1 - 2 sets

$1500.00 / 3 - 7 sets

$1200.00 / >=8 sets - 1 set

- Zhangjiagang Paima Import And Export Trading Co., Ltd.

- Jiangsu, China

- Mr Tony Zhao

PRODUCT DETAIL

| place of origin; place of origin: | Jiangsu, China | Processing Type: | Gravity pressure filling |

| Function: | automatic filling machine | Materials used for packaging: | plastic paper |

| Core components: | Motors, Pressure Vessels, Pumps, PLCs, Gears, Bearings, Gearboxes, Engines | Applies to: | water line |

| Auto grade: | automatic | brand: | Parma |

| Mechanical test report: | if | Health status: | new |

| Filling accuracy: | ±2mm | Advantage: | Running smoothly |

| Core parts warranty: | 1 year | Video external inspection: | if |

| payment terms: | L/C,Western Union,T/T | Mechanical Capability: | 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH |

| Warranty: | 1 year | Drive Type: | electrical |

| application: | Food & Beverage | Packaging Details: | Standard export wooden box |

| Filler: | beer, milk, water, oil, juice | Filling range: | 2-50ml 10-150ml 30-300ml 50-500ml 100-1000ml |

| Material: | Stainless Steel 304/316 | Name: | Bag/Bag/Sachet Water Machine |

| Marketing Type: | New Products 2022 | weight: | 300kg |

| type: | filling machine | port: | Shanghai |

| Packaging Preview: | Applicable industries: | Manufacturing Plants, Food and Beverage Plants, Farms, Food and Beverage Stores, Others | |

| usage: | Beverage filling and packaging | Filling liquid: | Purified water, mineral water, juice, milk, etc. |

| type of packaging: | Stand-up pouches, bags, bags | capacity: | 500-2000bph |

| Main selling point: | high accuracy | Voltage: | 380V/220V |

| Supply capacity: | 100 sets per month | Showroom location: | Egypt, Italy, Pakistan, Thailand, UAE, Kazakhstan, Uzbekistan |

| Dimensions (L*W*H): | 1800*1000*1500mm |

product description

Introduction of vertical bag water machine

The pouch machine can be used to fill pouches with various liquids such as water, juice, wine, alcoholic beverages, soy milk and various other liquids. This sachet machine has proven to be very reliable and is very commonly used in regions such as Latin America and Africa, but can be used anywhere in the world.

Product Specifications

Main features of sachet water filling machine

The sachet machine fills the pouches with water and then uses a heat sealing system to ensure that the filled pouches or pouches do not leak. Heat sealing also ensures that no adhesive, glue or resin is used to seal the bag, preventing any possible seal contamination. Heat sealing systems use a hot transverse vertical seal to seal the bag, which means that the bag is fed vertically and is heat (heat) sealed. It is designed for use with PE film or laminated film bags, making it suitable for a variety of applications. It can be used on films with preprinted logos or films without logos. The machine then cuts the pouches and places them in the finished product area.

Product configuration

Sachet/Sachet/Bag Water Filling Machine

Production capacity:

1500-2200 bags/hour

Filling range: 200-500ml

Voltage: 220v/380v 1.8kw

Solid width: 320mm/240mm

Package dimensions:

970 x 870 x 1970mm

Gross weight: 400KG / 880lbs

Mechanical Parts

1. High temperature cloth

2. Heater

3. Horizontal sealing strip

4. Vertical sealing strip

5. Silver Bar

6. Allen key set

7. Screwdriver

8. Open end wrench

9. Membrane foot pads

10. V-belt

11. Oil gun

The main function

1. Bag making (pouch/pouch) forming, filling and sealing

2. Ultraviolet sterilization

3. Heat vertical sealing

4. Date Lamination

5. Linear bag traction

6. Quantitative filling

7. Thermal Transverse Seal

8. Cut the bag

9. Automatic counting

whole series products

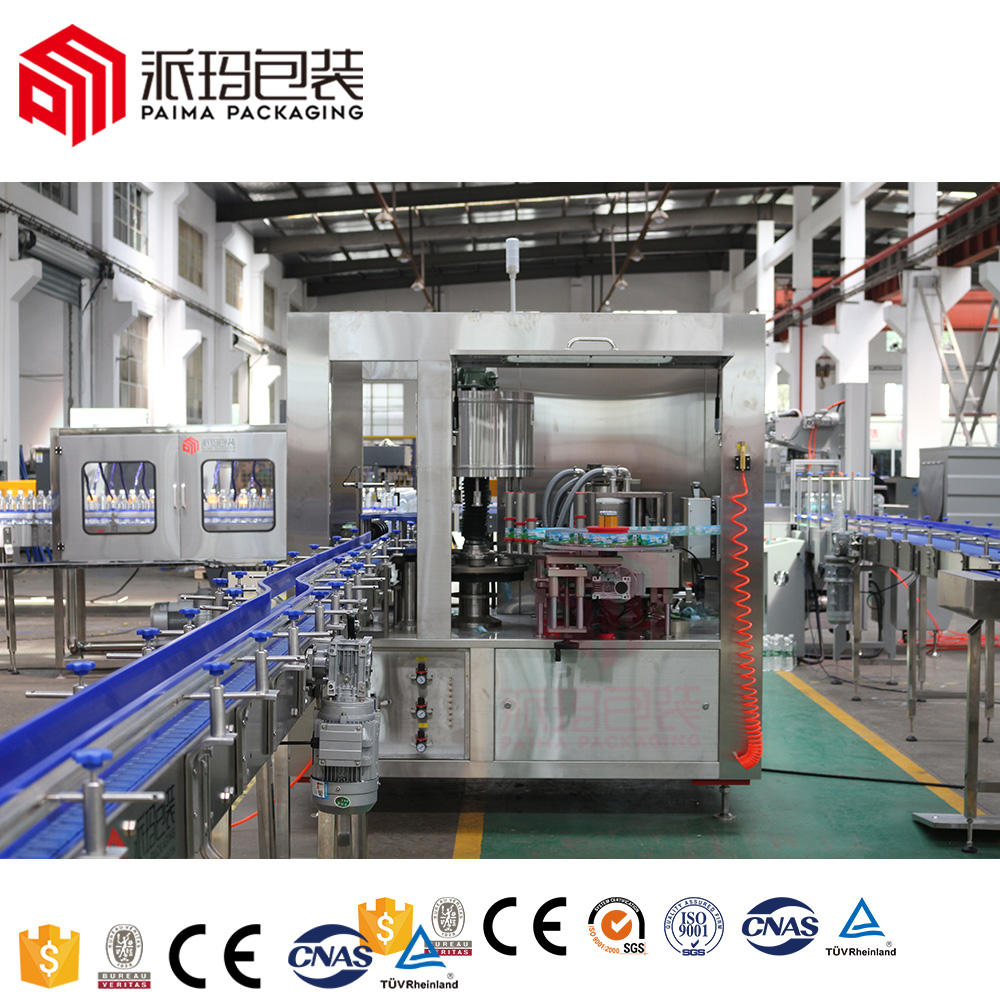

Complete bottled water production line

1. PET plastic bottle blowing system (semi-automatic/automatic)

2. Water purification system in water treatment system (sand filter, carbon filter, RO/UF, ozone sterilizer, ultraviolet sterilizer, etc.)

3. Empty bottle filling air conveyor

4. 3 in 1 Integrated Rinse-Fill-Capping Machine

5. Labeling machine (PVC sleeve labeling machine/OPP hot melt adhesive labeling machine/self-adhesive labeling machine)

6. Capper Loading Caps

7. Coding machine (inkjet printer/laser printer)

8. End packaging (PE film shrink packaging machine/carton packaging machine)

The water treatment system includes silica sand filter, activated carbon filter, sodium ion exchanger, ozone generator and ultraviolet sterilizer, RO machine (if it is mineral water, use hollow fiber filter). All of these machines are made of stainless steel food tables.

The fully automatic blow molding machine is suitable for producing PET plastic containers and bottles of various shapes. it is widely usedProduction of carbonated bottles, mineral water, pesticide bottles, oil bottles, cosmetics, wide-mouth bottles, hot-fill bottles, etc.

The air conveyor is fixed to the floor and the fan is mounted on top.

The bottles are held at the neck of the conveyor and conveyed into the filling machine by blowing air.

All made of stainless steel SUS 304/316.

The frame is welded from high quality carbon steel.

1. The machine is reliable and stable, and can be used in high-speed production lines.

2. The wind direction is adjustable. The tuyere can also be adjusted according to the actual situation.

3. Almost all kinds and sizes of bottles can be dried with this machine.

4. Low energy cost.

5. No accessories or parts to wear.

OPP labeling machine

The hot melt adhesive labeling machine is a kind of labeling machine equipment that can label the whole circle. The cut label pattern is complete and not deformed; The final mesh is glued, saving 50% of hot melt adhesive; Deviation correction ±0.05 (mm); Leakage of glue, no glue opening phenomenon.

1. Energy saving. Efficient. Adapt to customer factory layout.

2. Special lubrication system to keep the product clean, healthy and safe.

3. Extend the service life.

4. Electric eye design ensures safe and fast operation of the whole line.

5. The overload protection mechanism can effectively ensure the safety of the machine.

1. High-speed operation

2. High quality accessories

3. Powerful functions

4. Permanent Mark

5. Laser printed text is very clear

2. High quality accessories

3. Powerful functions

4. Permanent Mark

5. Laser printed text is very clear

Shrink wrapping machine

PE film shrink packaging machine is suitable for the packaging of mineral water, bottled beer, beverages and other bottomless trays (or trays with bottom). Perfect packing of goods together with PE shrink tunnel. The whole production process adopts German advanced technology.

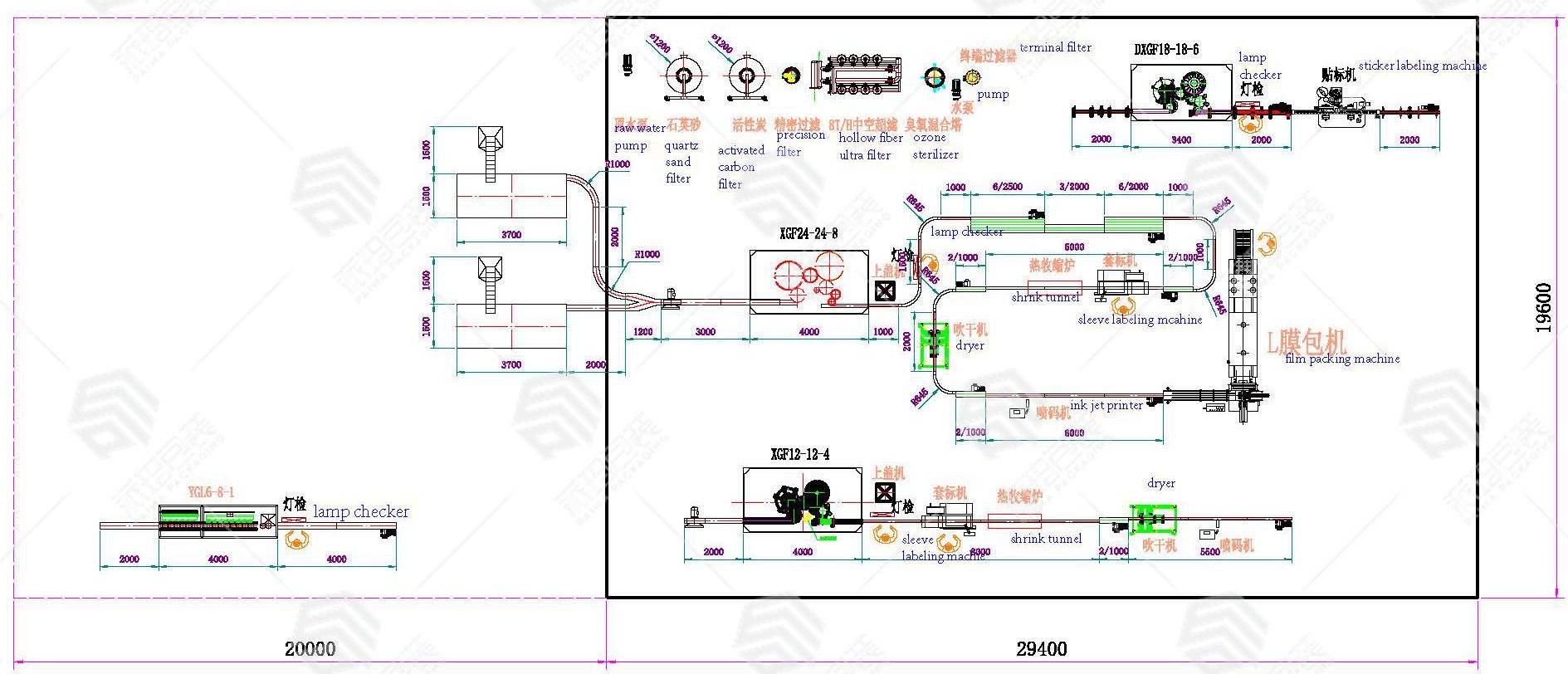

successful project

Real plant layout and water plant customer case

Choose the Pima packaging bottled water production line to help you set up a water plant:

1- Bottled water packaging solutions to better help you control the total cost of ownership;

2- Higher packing speed, more gentle global control system;

3-Safe and hygienic high-quality water production process;

4-Reduce energy consumption and utilize water resources more efficiently and rationally;

5-Accurately arrange your machinery and equipment according to your plant area;

Ethiopian Water Project

Yemen Water Project

Georgia Water Project

VIEW MORE

YOU MAY LIKE

Other Products

Related Searches

Pure Water

Pharmaceutical Filling Machines

Grain Cleaning and Grading Machines

Filling Machines

CNC Engraving and Milling Machines

Pipe and Tube Bending Machines

Water Filter Cartridge and Carbon Block

Shower and Laundry Water Purifiers

Soda and Sparkling Water Makers

Plastic Drying Machines