HPP sterilizer

- $14000.00 /set

- 1 set

- Inner Mongolia Yinda Trading Co., Ltd.

- Innnermongolia, China

- Mr Peter Wang

PRODUCT DETAIL

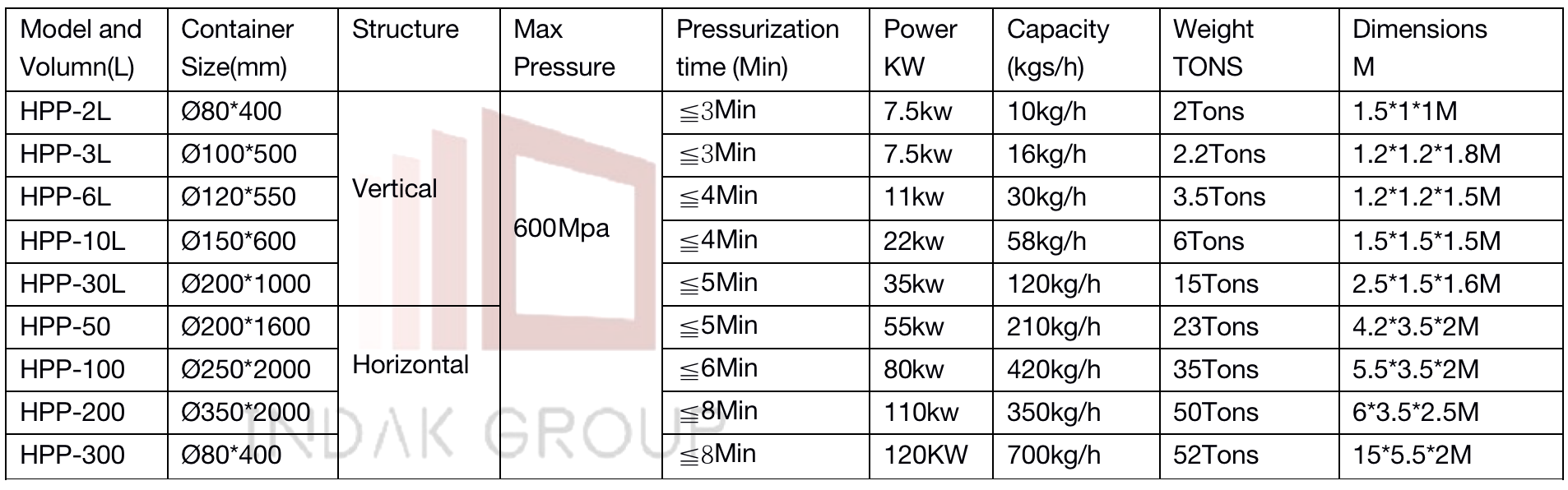

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Health status: | new |

| Container size: | 200-300mm | product name: | HPP sterilizer |

| Work pressure: | 600 MPa | Video outbound inspection: | if |

| Packaging Details: | wooden box | Processing: | Sterilizer |

| Origin: | Inner Mongolia, China | brand: | Refale |

| strength: | 110 kW | port: | Shanghai port |

| Processing type: | juice | Core component warranty: | 1 year |

| Custom processing: | Yes | Working medium: | water |

| Applicable industries: | Manufacturing plants, food and beverage factories, farms | Core components: | Engines, Bearings, Gearboxes |

| capacity: | 1-700 liters/hour | Dimensions (L*W*H): | 6000*2500*1600mm |

| Mechanical test report: | if | Sterilization method: | high pressure |

| Warranty: | 1 year | After-sales service provided: | Engineers available to repair machinery overseas |

| Showroom location: | Canada, Turkey, Italy, France, India, Thailand, Algeria, Sri Lanka | Material: | 316 |

| Voltage: | 220V/380V/415V/440V/480V | model: | HPP600Mpa/100L |

| Supply capacity: | 10 HPP sterilizers per month | weight: | 15 kg |

| Sterilization equipment type: | Ultra High Pressure HPP Sterilization | Marketing Type: | Hot Products of 2021 |

product description

Introduction to High Pressure Pasteurizer

Ultra-high pressure non-cooling effect pasteurizer means that there is no obvious temperature rise in the organism, but it can produce a strong biological reaction, causing various physiological, biochemical and functional changes in the organism, resulting in the death of bacteria and sterilization.

The main mechanism and advantages are as follows:

1. Ultra-high pressure can mutate the main components of food, nucleic acid and protein, and promote the death of microorganisms;

2. Ultra-high pressure will affect and interfere with the normal activities of DNA replication, transfer, synthesis and modification;

3. Common enzymes in food are sensitive to ultra-high pressure;

4. In the ultra-high pressure field, the cell membrane will be mechanically damaged, causing leakage of intracellular substances and affecting its growth and reproduction;

5. Ultra-high pressure reduces water activity and destroys the living environment of microorganisms; dipole molecules rotate and tend to be linearly arranged in the interactive sedimentation tank, resulting in changes in the secondary and tertiary structure of proteins, resulting in the death of bacteria and microorganisms

6. High pressure processing keeps food tasty and label clean

Application of HPP high pressure sterilizer

It keeps these foods and drinks safe and fresh:

•HPP juices and drinks

•meat

• Guacamole and salsa

• Ready-to-eat (RTE) meals

•fruits and vegetables

•seafood

• Explore the world of high pressure food processing applications

•HPP juices and drinks

•meat

• Guacamole and salsa

• Ready-to-eat (RTE) meals

•fruits and vegetables

•seafood

• Explore the world of high pressure food processing applications

scope

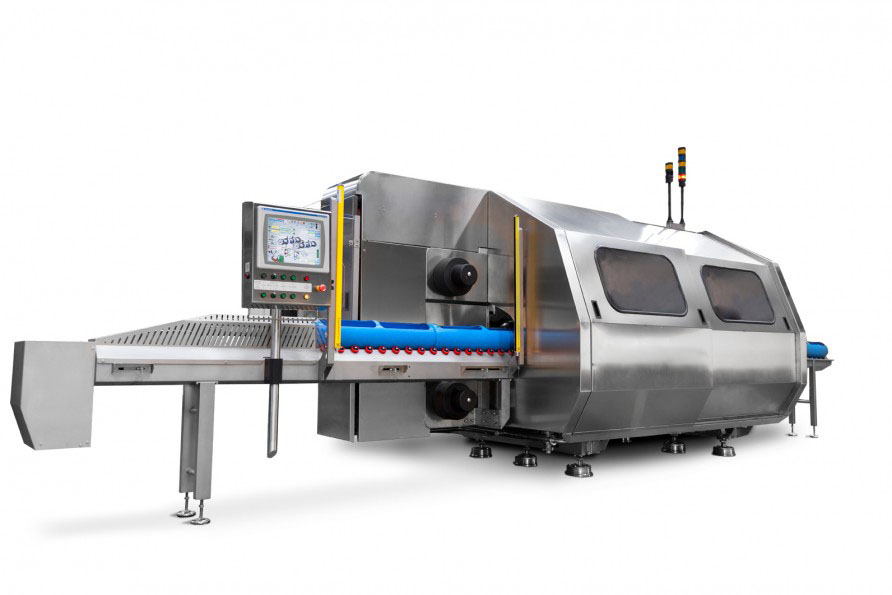

detailed image

VIEW MORE

YOU MAY LIKE