Haichen Horizontal Aluminum Radiator Cold Room Injection Molding Machine

- $77400.00 / 1 - 1 sets

$76900.00 / >=2 sets - 1 set

- Ningbo Haichen Servo Information Technology Co., Ltd.

- Zhejiang, China

- Mr kevin shen

| Voltage: | 380/220/440V | Local service location: | Turkey, Russia, Ukraine |

| Space between tie rods: | 760*760mm | Certification: | International Organization for Standardization |

| Foundry area: | 344-1433CM2 | Showroom location: | Turkey, Russia, Ukraine |

| strength: | 30KW | MOQ: | 1 set |

| Packaging Details: | Aluminum injection machine standard package | Package preview: | |

| Dimensions (L*W*H): | 8010*1985*2940mm | type: | Cold Chamber Die Casting Machine |

| Supply capacity: | 226 cold chamber die casting machines per month | Origin: | Zhejiang, China |

| Warranty: | 1 year | Type of machine: | Metal Die Casting Machine |

| Shot weight: | 4.1-6.8 kg | payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal, etc. |

| Material: | aluminum | After-sales service provided: | Engineers available to service machinery overseas |

| Main selling points: | competitive price | After warranty service: | Video technical support, online support |

| Open itinerary: | 610mm | weight: | 24000 |

| Applicable industries: | factory, construction | Health status: | new, new |

| port: | Ningbo Port | Mold thickness (minimum ~ maximum): | 90-1200 |

| brand: | Haichen |

Haichen Horizontal Aluminum Radiator Cold Room Injection Molding Machine

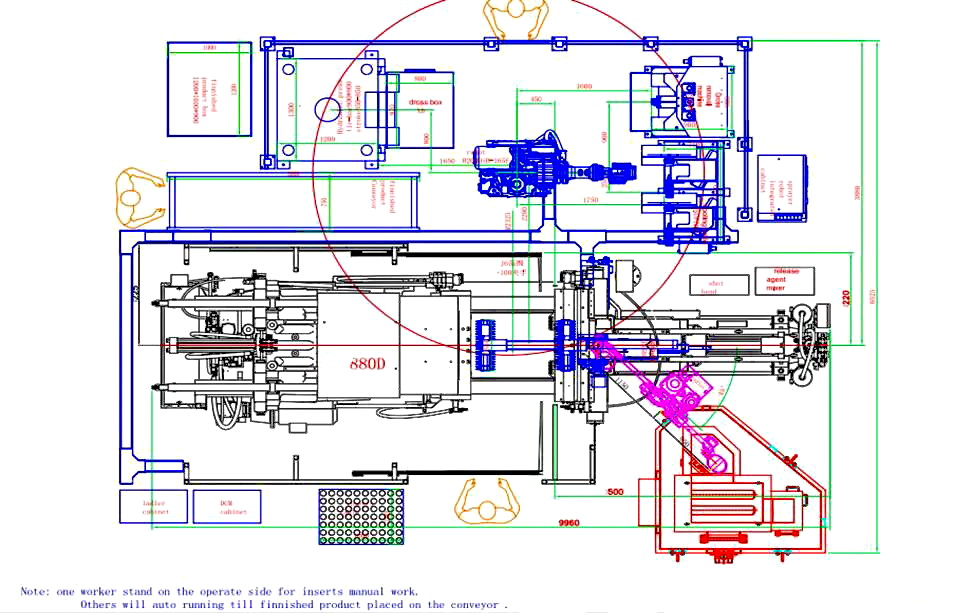

Haichen Die Casting Machine Factory provides fully automatic production lines.

Simple operation and professional design ensure quality and precision.

Our machines are suitable for automotive and motorcycle accessories, instruments, gauges, miscellaneous hardware, household appliances and other industry sectors.

• Multi-stage pressure and speed control mold clamping opening, with low pressure locking protection function.

• Hydraulically driven gear mold adjustment device.

• Central electric lubrication system.

• Rapid hydraulic ejector and core puller.

• Two-stage pressure and speed control injection, piston accumulator high-speed injection.

• German and Japanese famous brand hydraulic components.

• The advanced injection system can effectively stabilize the injection speed, and the air injection speed can reach 4m/s.

• Digital temperature control is adopted in the furnace to precisely control the temperature of the alloy material to avoid excessive or low temperature and improve the quality of die castings.

• The nozzle and gooseneck hotkey are made of high-temperature heat-processed steel to ensure long wear life.

Product name: aluminum radiator

Length: 50cm

Weight: 1200 grams

Name | for room heatingaluminum radiator |

work pressure | 1.5 MPa |

water capacity | 0.27-0.39L |

weight | 0.93-1.48Kg |

Aluminum Radiator Mold

PLC control unit

PLC LCD touch screen provides parameter setting and production monitoring functions. The machine adopts world famous electrical components to ensure stable, safe and reliable performance.

clamping device

High-strength wear-resistant cast formwork and toggles. The toggle system is guided by a double link tie rod to achieve fast, strong, durable and stable results. The hydraulic driven gear type mold thickness adjustment device makes the operation fast and ensures the precision.

Hydraulic system

The hydraulic system adopts proportional control system pressure and flow, realizes multi-stage pressure and speed control, and low-pressure mold closing function. European or Japanese famous brand valves and oil seals ensure quality and durability; famous brands improve performance. High-low noise double pump or single pump, saving energy and improving production efficiency.

injection device

2-stage injection control with piston accumulator and high-flow cartridge valve realizes high-speed operation and stable injection. All thermal parts are made of high-quality steel to ensure stable operation in high temperature, high pressure and high speed environments.