High Precision Automatic Portable Welding Line Boring Machine

- $5000.00 /set

- 1 set

- Zhejiang Wellnit Mechanical Technology Co., Ltd.

- Zhejiang, China

- Mr Linhua Xiang

| Video external inspection: | if | year: | 2020 |

| Applicable industries: | Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Restaurants, Retail, Construction Engineering, Energy and Mining, Excavators | Drilling diameter: | 55-300mm |

| Dimensions (L*W*H): | 80*80*73 | Showroom location: | United Arab Emirates, South Africa |

| Supply capacity: | 3 sets per week | Packaging Preview: | |

| Health status: | new | Weight (kg): | 30 |

| Voltage: | 220V | automation: | automatic |

| After-sales service provided: | Online support | Mechanical test report: | if |

| Material/Metal Finishing: | Brass/Copper, Stainless Steel, Carbon Steel, Aluminum Alloy, Alloy, Aluminum | Core components: | motor |

| rated power: | 2kW | Marketing Type: | Hot Products of 2019 |

| Drill length: | can be customized | place of origin; place of origin: | China |

| port: | Ningbo, Shanghai | Main selling point: | high accuracy |

| brand: | healthy | Feeding method: | automatic |

| Core Components Warranty: | 1 year | Packaging Details: | plywood |

| spinning speed: | 0-118 rpm | payment terms: | letter of credit, wire transfer |

| Warranty: | 1 year |

High Precision Portable Linear Boring Machine

Performance

LB series linear boring machine is a portable and efficient product. The machine adopts high-strength alloy structural steel, which is more wear-resistant. Modular design of the whole machine, equipped with rotating structure and automatic feeding device, high precision. The boring parts can be replaced, and different joints can be selected to realize inner hole repair, pipe surface processing, taper hole boring, end face milling, flange end face processing, etc. Widely used in excavators, lifting machinery.

Specification

| drive |

Model |

Boring diameter |

spinning speed |

|

electrical (LBE)

hydraulic (LBH)

CNC (London Business School) |

50 |

55-400mm |

0-118 rpm |

|

60 |

65-600mm |

0-118 rpm |

|

|

90 |

100-800mm |

0-78 rpm |

|

|

110 |

180-900mm |

0-62r/min |

|

|

150 |

220-1000mm |

0-55r/min |

|

|

200 |

380-1200mm |

0-38 rpm |

|

|

300 |

460-1600mm |

0-28r/min |

notes:

Wire boring bar length: 2500 / 3000 / 3500 / 4000 / 4500 mm

(different lengths can be customized)

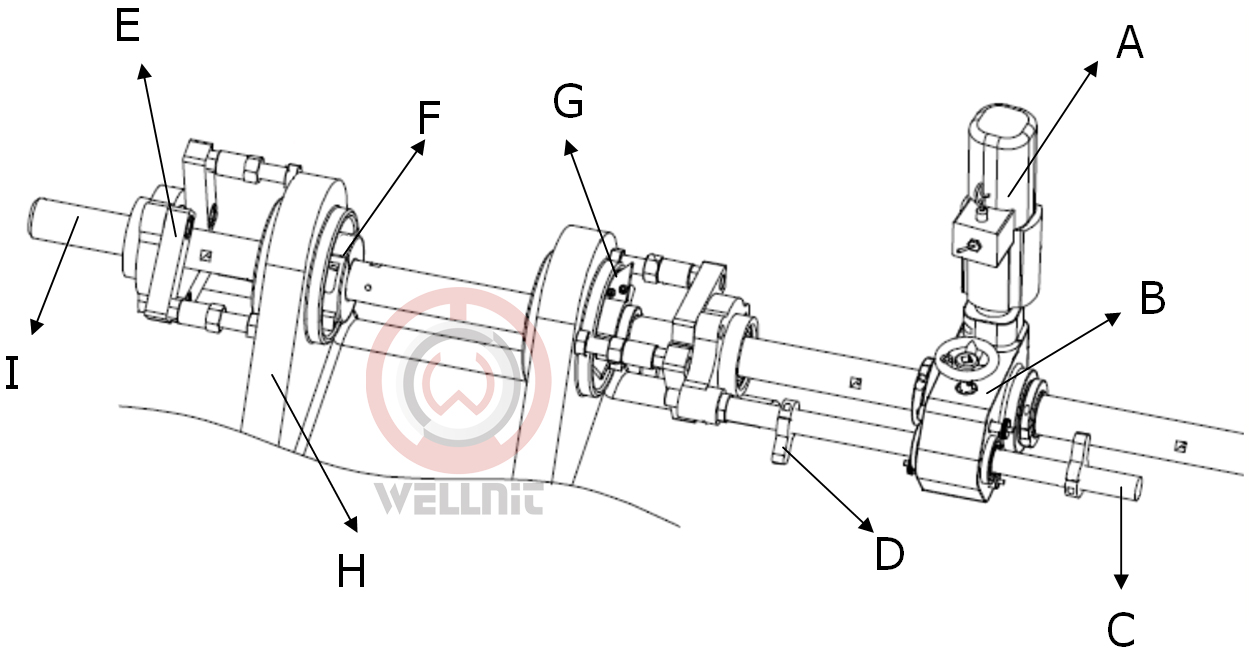

product structure

- Choose different models according to workpiece size

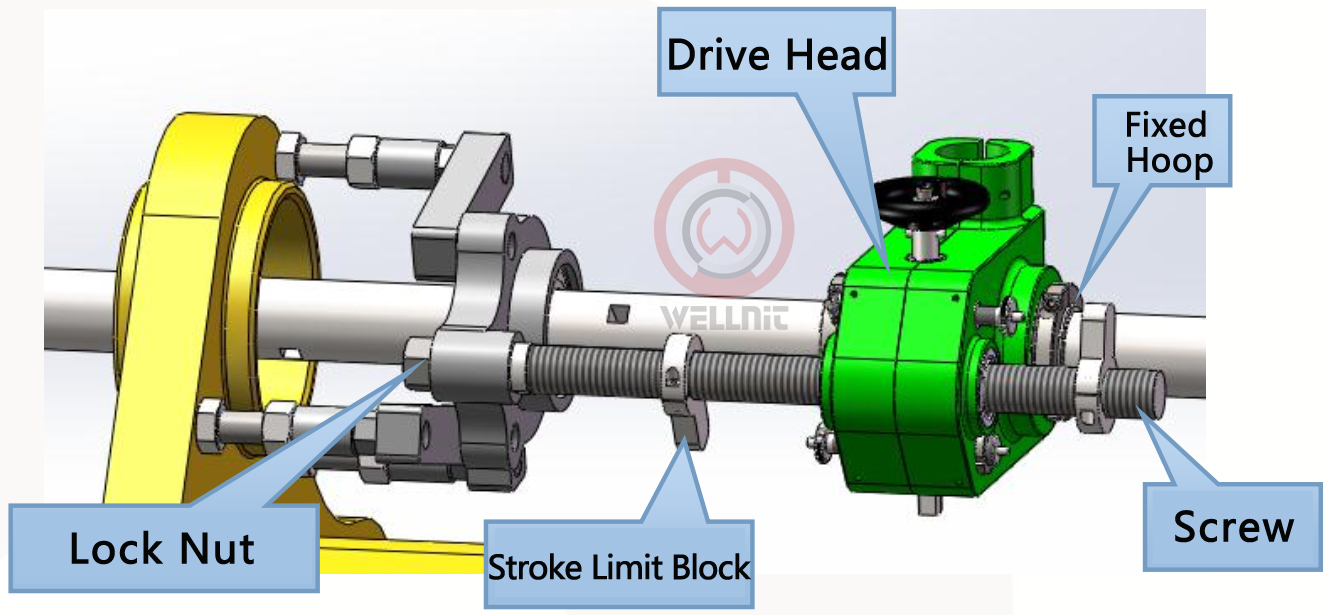

- Fix the boring bar by the support mechanism

- Install the driver

- The machine is equipped with a travel limit block, which can determine the processing

- Stroke according to processing needs

- The machine can feed automatically, with high processing efficiency and smooth processing surface

On-site processing

pack