High precision 4140 chromium molybdenum steel

- $1.02 /kilogram

- 1 kilogram

- Changzhou Drake International Trade Co., Ltd.

- Jiangsu, China

- Ms Joanna Zhou

| Steel pipe color: | Steel pipes and bars | Supply capacity: | 800 tons of high-precision 4140 chromium-molybdenum steel per month |

| Place of origin: | Jiangsu, China | Surface treatment: | polished, galvanized |

| Steel pipe material tolerance: | Steel pipe +/-0.03mm | Steel pipe technology: | Cold drawn and cold rolled |

| technology: | Cold drawn | Cross-sectional shape: | round |

| Certification: | ISO9001:2008 | Steel pipe shape: | round steel pipe |

| Steel pipe product name: | High precision 4140 chromium molybdenum steel | Steel pipe material: | 4140 Chromium Molybdenum Alloy Steel Pipe |

| Steel pipe tensile strength: | ≥1080(110)(MPa) | port: | Shanghai, Ningbo, Qingdao, Dalian, Tianjin, etc. |

| payment terms: | Steel pipe L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal | Special pipes: | thick wall tube |

| Yield strength of steel pipe: | ≥930(95)(MPa) | Outer diameter: | 3 - 80 mm |

| thickness: | 0.5 - 8mm | Packaging details: | 1. Steel pipe wrapped with waterproof paper 2. Steel pipe with several steel strips and linen cloth 3. Steel pipe cap 4. Steel pipe wooden box |

| grade: | 10#-45#,10# | Secondary or not: | non-secondary |

| application: | Drill pipe, fluid pipe, hydraulic pipe, oil pipe, structural pipe | Steel pipe length: | Customer requirements |

| standard: | ASTM, ANSI A213M-2001 | Whether alloy: | It's an alloy |

High precision 4140 chromium molybdenum steel

4140 alloy seamless steel pipe

| chemical composition(%) | Mechanical behavior | |||||||||

| C | silicon | manganese | S | phosphorus | chromium | you | copper | Mo | Yield Strength | tensile strength |

| (σ) | (σb) | |||||||||

| 0.38~0.45 | ≤0.40 | 0.60~0.90 | ≤0.035 | ≤0.035 | 0.90~1.20 | ≤0.40 | / | 0.15~0.30 | ≥930(95)(MPa) | ≥1080(110) |

| (MPa) | ||||||||||

| end shape | Bevel ends, plain ends, disappear or add plastic caps to protect ends According to customer's requirements | |||||||||

| surface | Oil coating, galvanizing, phosphating, etc. | |||||||||

| treat | ||||||||||

| technology | Cold drawn | |||||||||

| application | 1. Pipes for automobiles and machinery | |||||||||

| 2. Petroleum cracking pipe | ||||||||||

| 3. High pressure boiler tube | ||||||||||

| 4. Low and medium pressure fluid transportation pipelines | ||||||||||

| 5. Fertilizer equipment pipelines | ||||||||||

| 6. Heat exchanger pipes | ||||||||||

| deliver goods | 1. Midriff (+C) | No heat treatment is required after the last cold forming. | ||||||||

| situation | 2.BKW(+LC) | After the last heat treatment, a light finishing process (cold drawing) is performed | ||||||||

| 3.BKS (+SR) | After the final cold forming process, the tube is stress-relief annealed. | |||||||||

| 4.GBK(+A) | After the final cold forming process, the tubes are annealed in a controlled atmosphere. | |||||||||

| 5. NBK (+N) | After the final cold forming process, the tube is annealed in a controlled atmosphere at a temperature above the upper transformation point. | |||||||||

| pack | 1. Bundle packaging. | |||||||||

| 2. According to customer requirements, flat end or disappear. | ||||||||||

| 3. Wrap with waterproof paper. | ||||||||||

| 4. There are several steel strips on the burlap. | ||||||||||

5. Pack into heavy-duty three-wall box. | ||||||||||

ee japan takes care of you jizz tube free japan takes care of you jizz tube free japan takes care of you jizz tubeFree japanese tube every time you cum

Our seamless steel pipes are capable of producing all of the following products:

Fuel injection pipe, oil flow pipe | Automobile and motorcycle shock absorber tubes |

| seat riser | Hydra-cylinder tube |

| Bicycle frame steel pipe | Mechanical steel pipes for automobiles and motor parts |

| Automobile and motorcycle accessories | Generator exhaust pipe |

| high heels steel tube | Wind chime seamless steel pipe |

| Bicycles and bicycle frames | Hydraulic system (oil pipe, motor pipe) |

| Sewing and textile machine parts | Air Conditioning Parts |

| gasoline burner tube | oil pipeline drilling |

| Automobile and motor pipe fittings | Gas spring tube, motor casing |

steel pipe steel pipe steel pipe steel pipe steel pipe steel pipe steel pipesteel pipe steel pipe steel pipe steel pipesteel pipe steel pipe steel pipe steel pipe

steel pipe steel pipe steel pipe steel pipe steel pipe steel pipe steel pipesteel pipe steel pipe steel pipe steel pipesteel pipe steel pipe steel pipe steel pipe

I don’t care about jizz, I don’t care about free Japan, I don’t care about you j

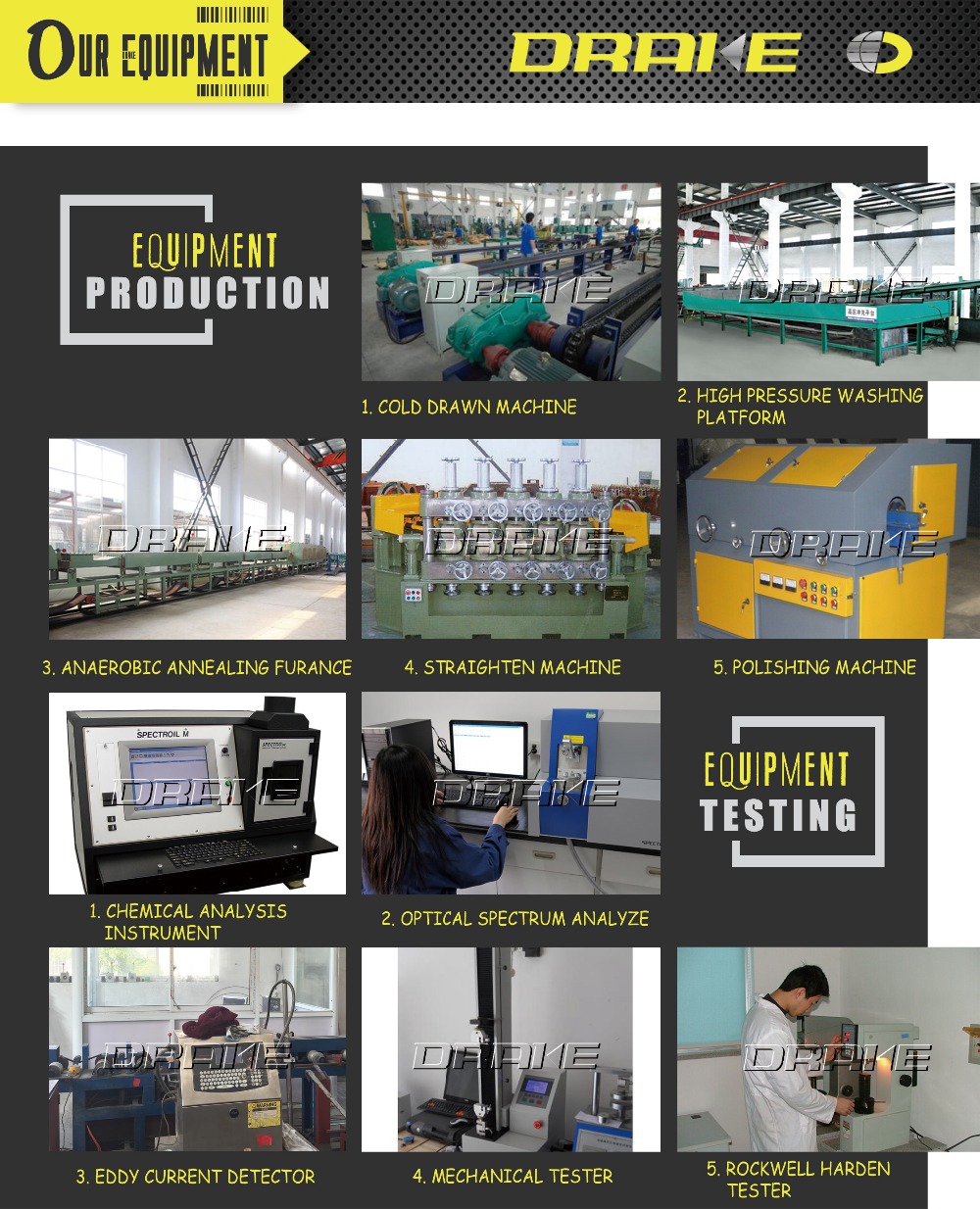

| Equipment production: | Equipment testing: | |

| | ||

| 1. Cold drawing machine; | 1. Chemical analysis instruments; | |

| 2. High pressure cleaning platform; | 2. Spectral analysis; | |

| 3. Oxygen-free annealing furnace; | 3. Eddy current detector; | |

| 4. Straightening machine; | 4. Mechanical tester; | |

| 5. Polishing machine. | 5. Rockwell hardness tester. |

1. We use special technology and special techniques during the pickling process to deal with places where folding gaps are easy to form;

2. The process organization is strict, especially the annealing treatment, which has strict technical requirements;

3. In terms of lubrication, we adopt internationally advanced processing technology to strictly control the surface quality of the product to prevent surface cracks.

steel pipe steel pipe steel pipe steel pipesteel pipe steel pipe

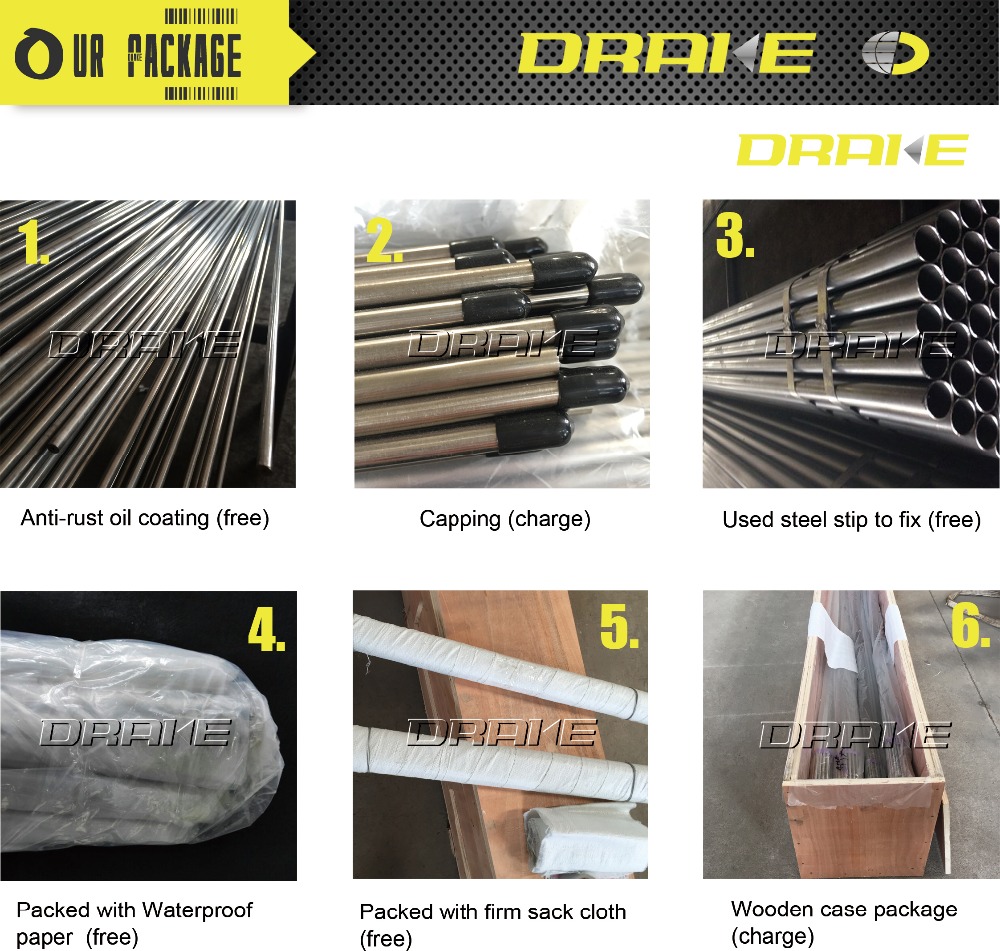

1. Anti-rust oil coating (free)2. Capping (charging)

3. Fix with steel bars (free)4. Waterproof paper packaging (free)

5. Packed in sturdy linen cloth (free)6. Wooden box packaging (charged)