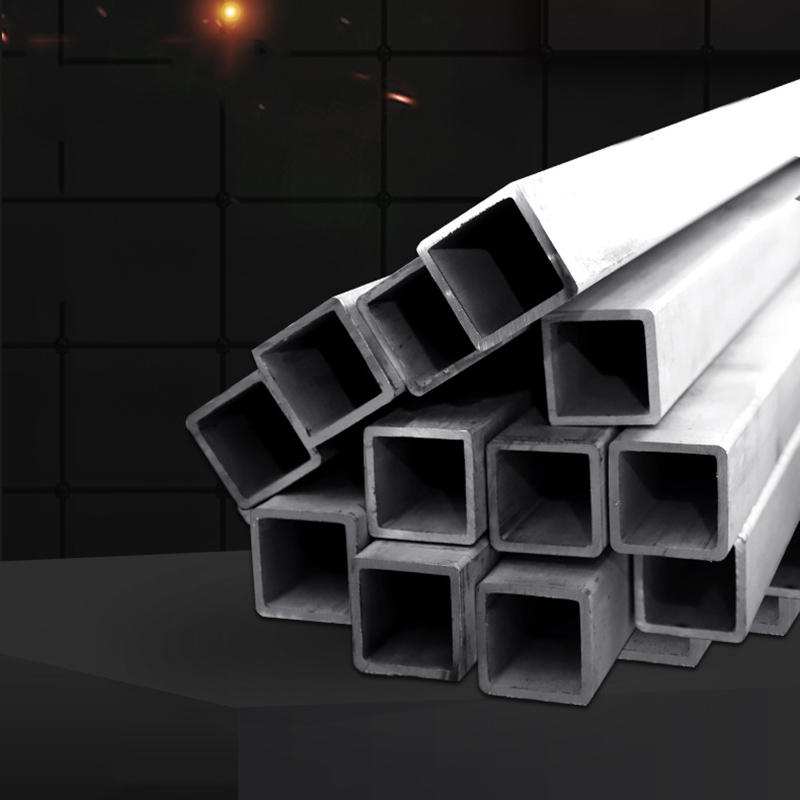

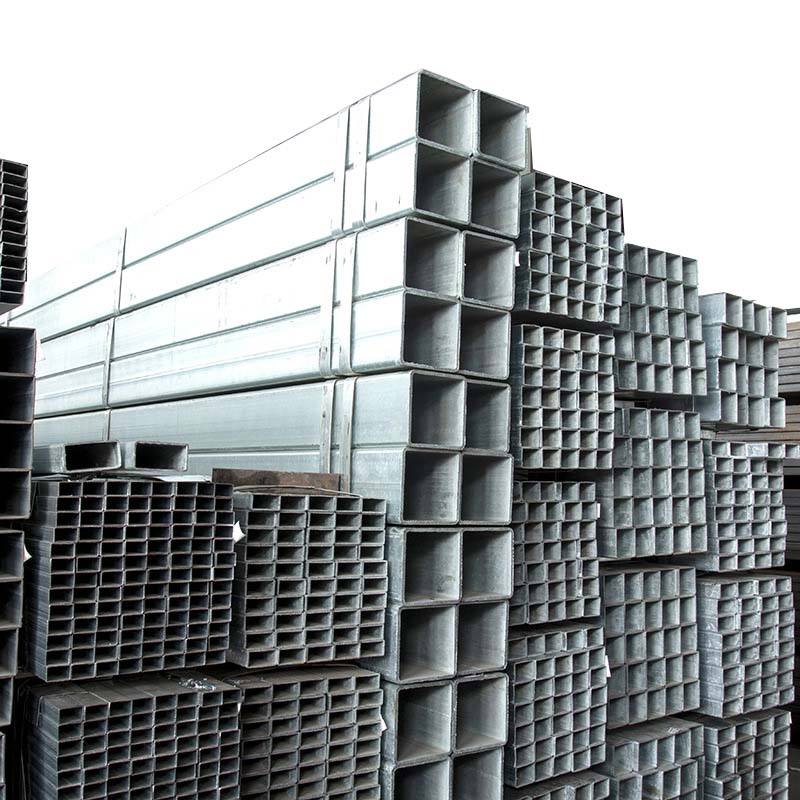

Hot Dip Galvanized Steel Pipe / Pre-Galvanized Steel Pipe

- $0.84 / 3000 - 9999 kilograms

$0.79 / >=10000 kilograms - 3000 kilograms

- Guangzhou AJ Building Material Co., Ltd.

- Guangdong, China

- Mr Oscar Ou

PRODUCT DETAIL

| Packaging Details: | Scaffolding galvanized iron pipes are hardly packaged in containers or according to your requirements. About 1400 pieces per 20GP. | thickness: | 2.75 - 3.25 mm |

| bill: | by actual weight | Oiled or unoiled: | no fuel |

| tolerant: | ±1% | Surface treatment: | Galvanized |

| application: | building, structural pipe | standard: | BS 1139, BS |

| usage: | building structure | Material: | Q235 steel pipe |

| Tube Thickness: | 2.75/3/3.25mm | technology: | Hot rolled and welded |

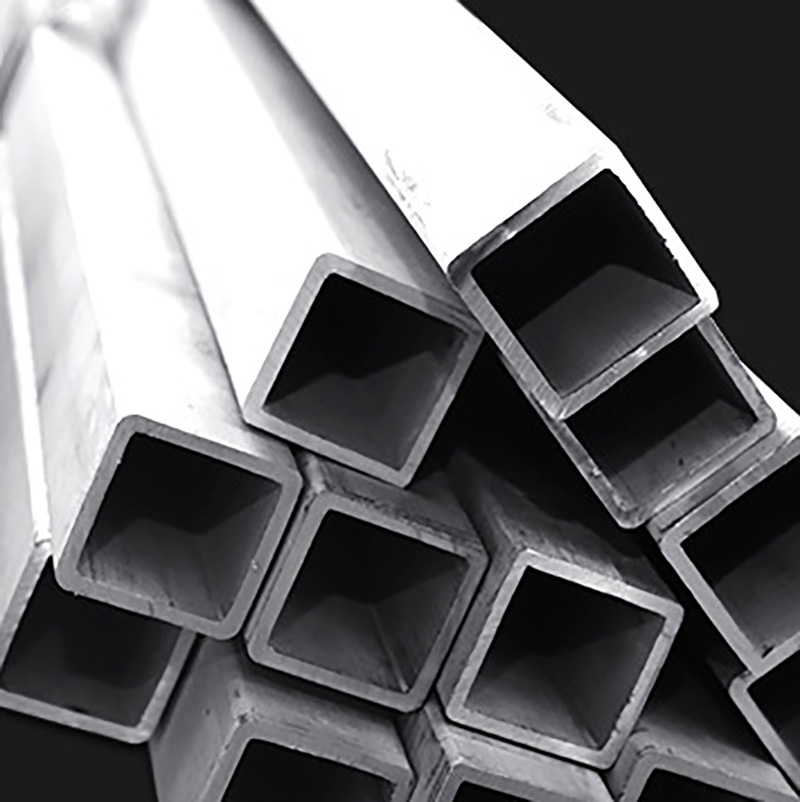

| Processing service: | welding | Section shape: | square |

| port: | Guangzhou | life: | 5+ years |

| grade: | Q195-Q345,Q235 | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Cash |

| color: | Available in silver (galvanized), nude or painted pipes | delivery time: | 30 |

| type: | Scaffolding Galvanized Iron Pipe | Supply capacity: | 30,000 tons/month |

| place of origin; place of origin: | Guangdong, China | Special tube: | thick wall tube |

| Alloy or not: | non-alloy | length: | 6m |

Specification

Material | Q195/Q235/Q345 carbon steel | |||||

surface treatment | Silver (galvanized), nude or painted | |||||

color | silver, black or as required | |||||

Welding Technology | CO2 arc welding | |||||

Product Description

feature

1. The scaffolding galvanized iron pipe is made of Q235 steel, which has high strength and durability.

2. Scaffolding galvanized iron pipes can be connected with suitable joints at any angle. They are wonderful successors

Standard scaffolding and steel struts.

3. Scaffolding galvanized iron pipes are widely used in construction and real estate, which are cheap and convenient.

4. Scaffolding galvanized iron pipe is multifunctional; it can be cut to any length according to customer requirements.

2. Scaffolding galvanized iron pipes can be connected with suitable joints at any angle. They are wonderful successors

Standard scaffolding and steel struts.

3. Scaffolding galvanized iron pipes are widely used in construction and real estate, which are cheap and convenient.

4. Scaffolding galvanized iron pipe is multifunctional; it can be cut to any length according to customer requirements.

High bending and torsional strength, strong ability to withstand external forces, not easy to deform, light weight, easy to transport

The surface of the product is smooth. The cutting is smooth and burr-free, and has good museum resistance. Accurate scale, high strength, wide application range, multi-purpose, multi-specification

Custom processing

It can produce fixed thickness, width and length according to user needs, which reduces cutting and saving processes for users, reduces labor and material consumption, and also reduces processing loss of raw materials, saving time, labor and materials.

scenes to be used

VIEW MORE

YOU MAY LIKE

Other Products

-

Metal construction scaffolding telescopic adjustable galvanized steel props support$8.90 - $12.90 / piece

Metal construction scaffolding telescopic adjustable galvanized steel props support$8.90 - $12.90 / piece