High quality 3D EPS panel machine with CE certificate

- $80000.00 /set

- 1 set

- Yantai City Hede Machinery Equipment Co., Ltd.

- Shandong, China

- Mr Messi Luan

| Showroom location: | not any | Applicable industries: | factory, construction |

| Automatic degrees: | Fully automatic | Welding wire: | Galvanized wire |

| Local service location: | not any | After-sales service provided: | Online support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support |

| Production capacity: | 800 sqm/8 hours | Panel thickness: | 50mm to 200mm |

| strength: | custom made | place: | Shandong Province |

| Supply capacity: | 50 sets per year | port: | Qingdao Port |

| Main selling point: | Fully automatic | use: | thermal insulation wall |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | raw material: | EPS and Wire |

| Health status: | new | type: | vertical |

| Advantage: | Fireproof and light weight, easy to install | Warranty: | 1 year |

| After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

3D EPS screen board machine

3D EPS screen board machine introduction

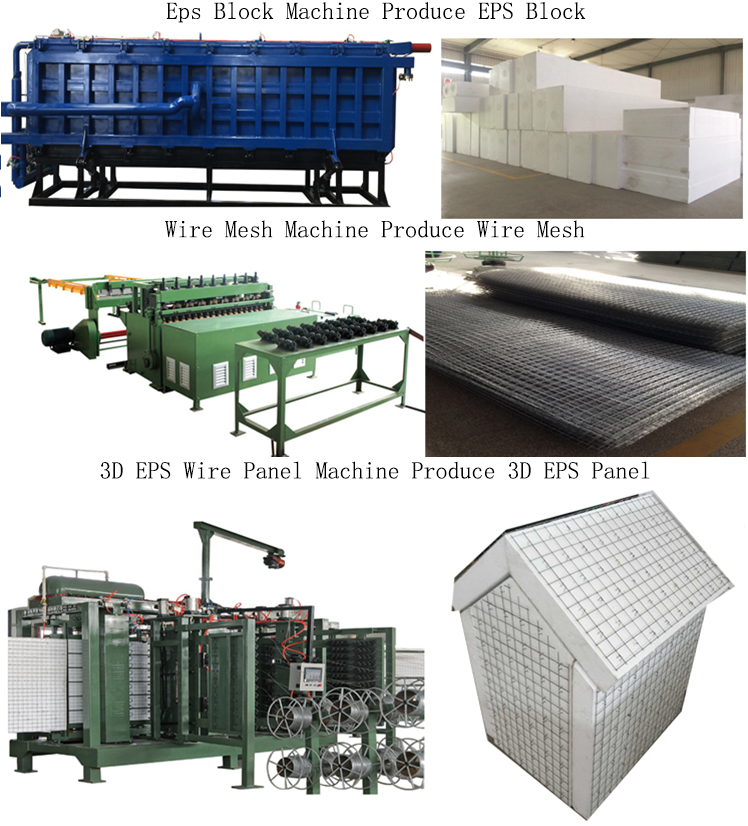

Vertical 3D panel production line is a fully automatic factory with electronic process control, which can accurately produce 3D panels of different thicknesses and lengths with high precision and strong weld seams, providing builders with superior quality products.

Especially the vertical 3D panel machine has the following characteristics:

1. It can produce 3D panels of single-layer and double-layer external wall insulation system with high production capacity.

2. The equipment integrates the pneumatic system to ensure stable operation, high reliability and long service life of the equipment.

3. The wire feeder of the A-type equipment is a pneumatic system, and the welding angle is not adjustable.

4. The wire feeder of type B equipment has a pneumatic clamping device, and the welding angle is adjustable.

5. With self-inspection capability and automatic alarm system, it is easy to operate and maintain.

6. It can also produce mineral wool 3D panels. Hot Selling EPS 3D Grid Trigger

3D EPS Panel Introduction

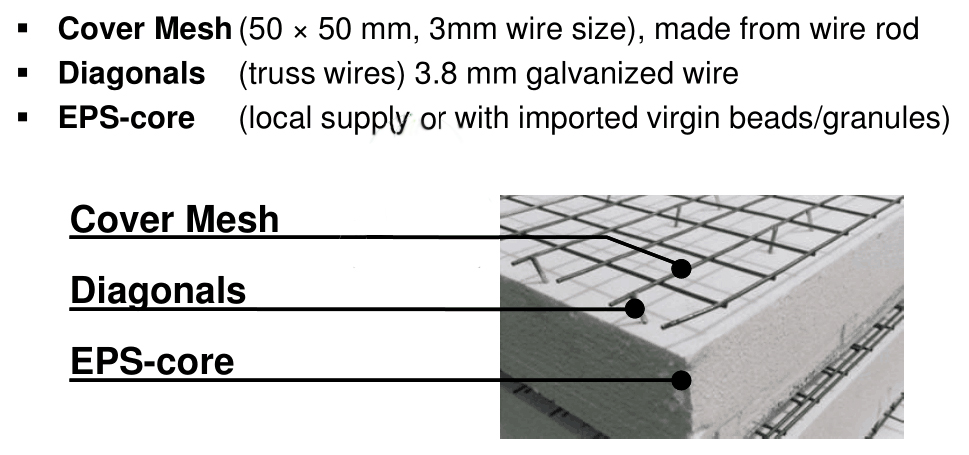

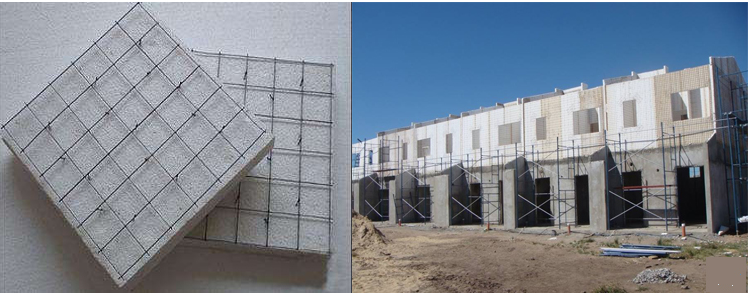

3D wire mesh board is a new type of building material with good insulation performance, light weight and high strength. Three-dimensional steel mesh and truss are used as the skeleton, and EPS or rock wool board is used as the insulating core layer. The 3D panels can be widely used as wall, roof and floor materials, with concrete sprayed on both sides, the concrete will adhere very firmly to the core board.

Compared with horizontal 3D panel machines, our vertical 3D panel machines are more productive than horizontal ones and have many advantages over horizontal ones.

3D EPS screen board machine exhibition

3D EPS screen board machine application

3D EPS screen board machine application

3D EPS screen board machine technical parameters | ||

cable: | 2-4mm galvanized or non-galvanized. | |

Mesh (mm) : | 50 x 50, 75 x 75 and 100 x 100. or customized | |

Truss line: | 2-4mm galvanized or non-galvanized. | |

Control panel: | 1220mm. | |

Panel length: | 2400mm, 3000mm and 6000mm. or customized | |

EPS insulating core: | 50-240 mm. | |

productivity | 600-800 sqm every 8 hours | |

3D EPS screen board machine workflow

3D EPS screen board machine production

3D EPS screen board machine shipped

our service

1. High quality

The main components of the foaming machine production line are imported from world famous factories. Such as Siemens; Delixi; Omron, etc.

2. Competitive price

Due to the advanced technology, our eps block making machine has a competitive price. So we are the best partner of your choice!

3. Innovation

Our team develops new solutions for different clients with different needs.

Related machines

EPS building block machine EPS profile forming machine