High quality cold chamber die casting mold aluminum casting parts

- $10000.00 / 1 - 1 sets

$9500.00 / >=2 sets - 1 set

- Dengfeng (Zhaoqing) Trading Co., Ltd.

- Guangdong, China

- Mr Jacky Qiu

PRODUCT DETAIL

| Application: | Furniture; | Packaging Detail: | Wooden crate for mold, Good cartons for casting product with pallet packing; |

| Mould Type: | Family Cavity Molds; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Model Number: | df0096; | Material: | ADC12,A380,Zinc, Copper alloy; |

| Port: | Yantian; | OEM: | Welcome; |

| Brand Name: | dfmold; | Packing: | Carton+pallet; |

| Mould material: | H13,SKD61,SKD11,2344 etc; | Supply Ability: | 20 Sets per Month; |

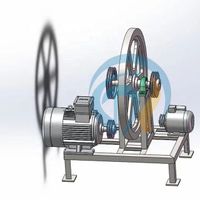

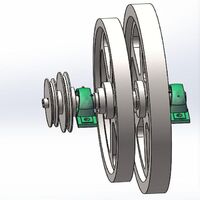

| Quality: | Guaranteed; | Equipment: | Die Casting Machine; |

| Package Preview: | ; | Place of Origin: | Guangdong, China; |

| Manufacturing Process: | Casting.CNC; | Surface treatment: | Heat Treatment; |

Recommend Products

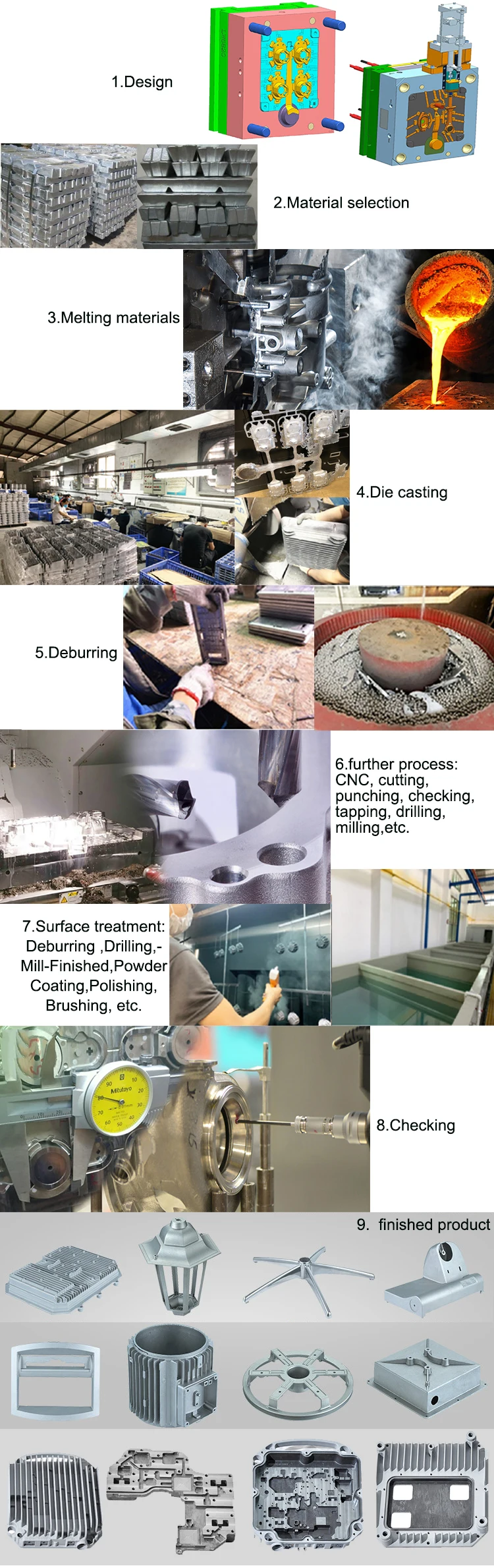

Products Description

We improve the quality of aluminum alloy and zinc alloy products for our customers. We implement the most stringent standards to ensure the optimization of design, material and process.

Model Name | coldchamber die casting mold |

part Material | A380,A413,A360,Adc12,A325,ZL102,ZL104 etc. |

Process | DFM--Cut steel--Aluminium die casting-- cnc machining-- threading--sand blasting-- black anodizing--assembing--packing |

Mould Base | SD,LKM Standard, HASCO Standard Self-made, etc. |

Mould Material | SKD11,/DC53/2344/2316/H13, etc. |

Mould Cavity | single or mulity etc. |

Mold surface | Nitriding+Heat treatment, surface hardness 58-60HRC |

Runner type | Cold-Chamber system |

product packing and shipping

Our Advantages

1. We choose the best quality materials to match the customer's product requirements.

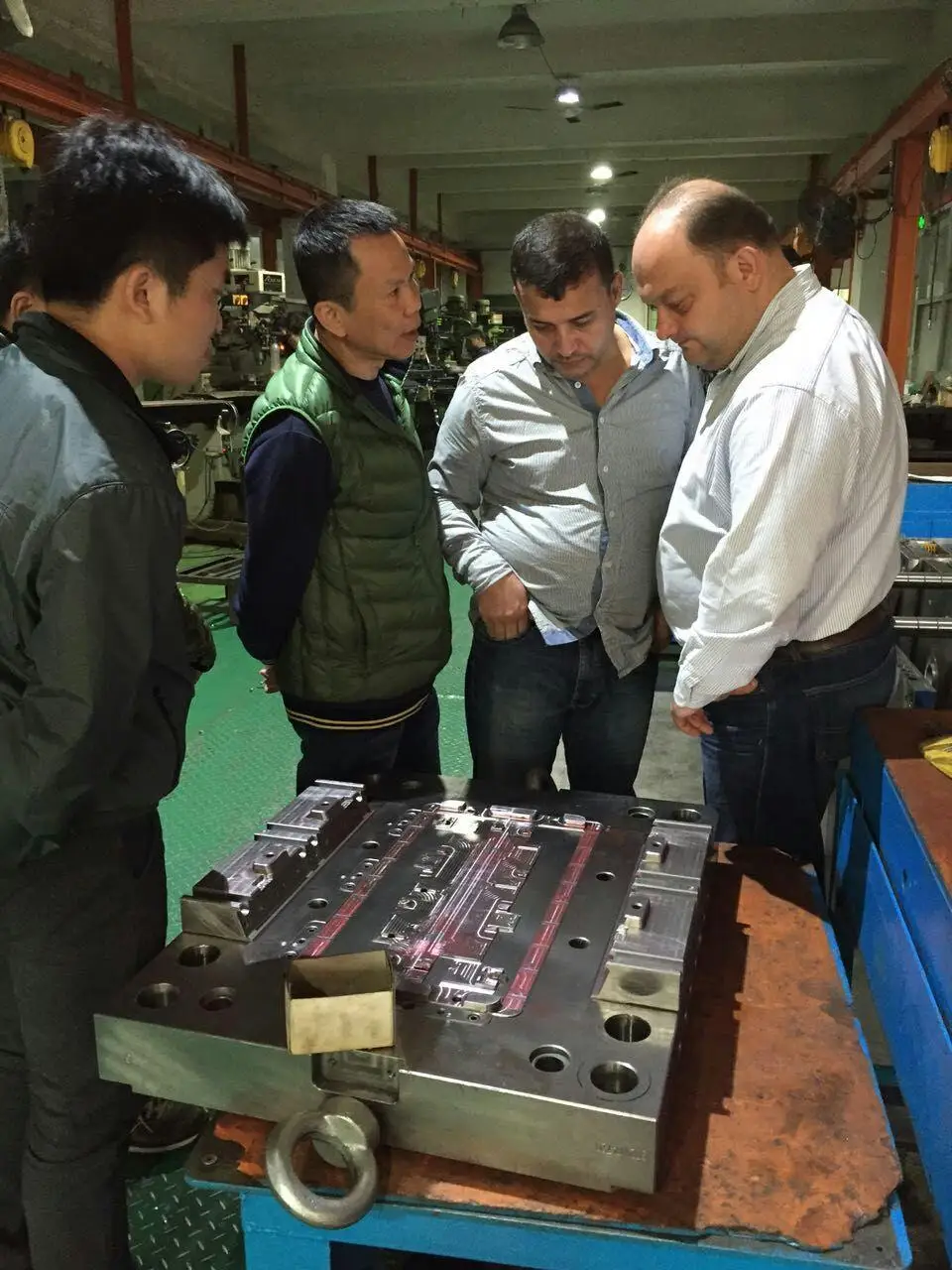

2. We have the most professional technical team.

Jacky is the leader of our technical team. He has more than ten years of working experience. He led the technology to provide the best mold and product design, to ensure the quality of mold and product production. The team can provide after-sales quality and technical support and guarantee for molds and products.

3. We have a scientific production process to ensure product quality.

Company Profile

Since its establishment, Dengfeng Mold Co., Ltd. has been committed to the establishment of plastic and aluminum injection mold and precision turning services. We have a professional engineering team, with more than 15 engineers, good at part structure design, injection mold manufacturing, precision turning and secondary processing technology.

We can make non-standard customized products according to customers' drawings and samples. Our factory has CNC lathe, CNC machining center, five axis machining center, high precision CNC punch, bending machine and CMM imported from Germany. We specialize in the whole assembly, precision machining, general machining, automatic turning, anodizing, electroplating, and provide a variety of processing services for different fields.industries.

Customer Photos

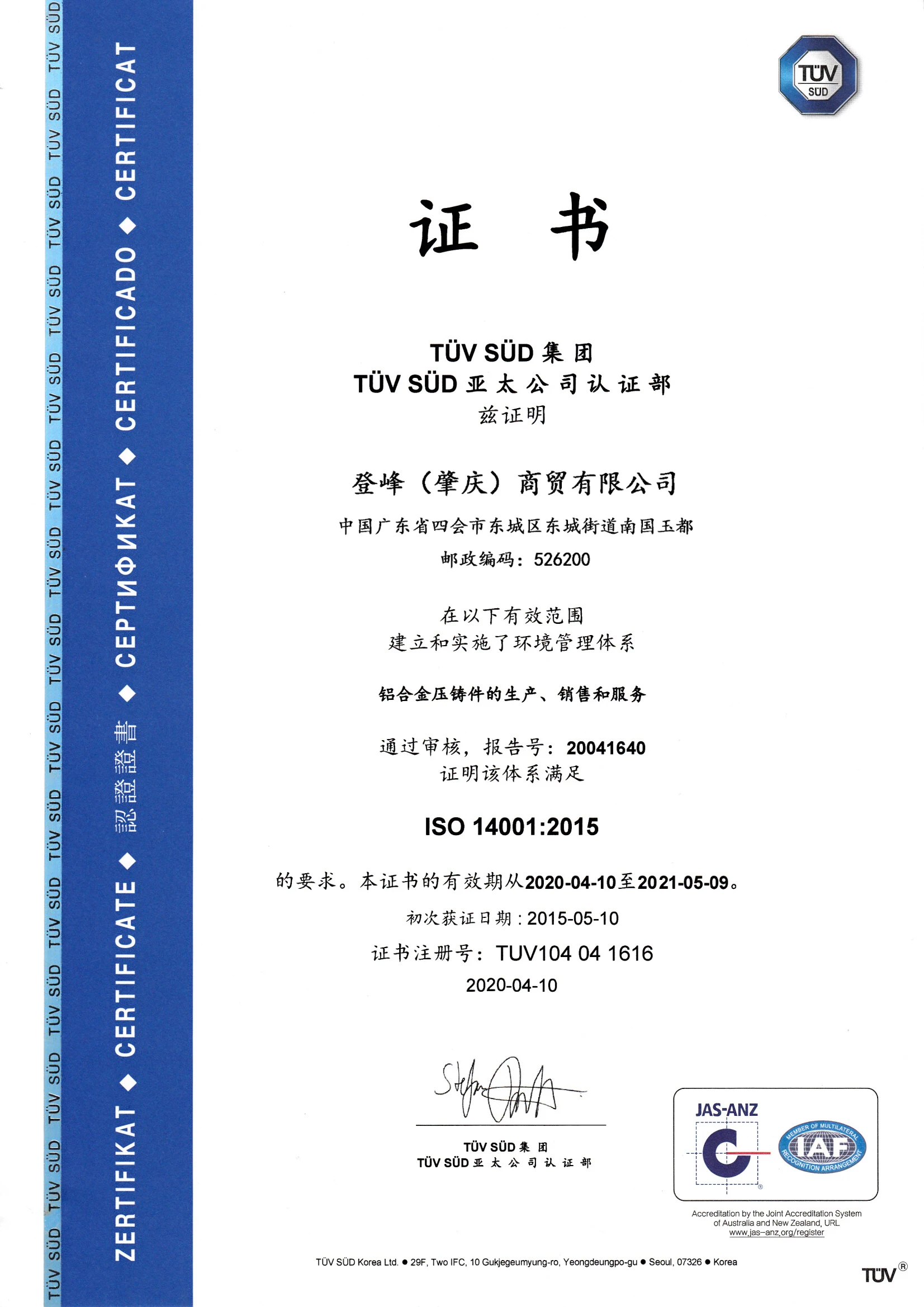

Certifications

FAQ

Q: How can I get the quotation?

A:We will submit the quotation in 24 hours if getting detailed information during working days.In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files or 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q: How to enjoy the OEM services?

A: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q: How soon can I get samples? And how long is the lead-time for mold?

A: Depending on your specific project,it usually takes 10 to 20 days to get samples.The lead time is 25-35 days. If the molds are very simple and not big size,we can work out within 15 days.

Q5: Before shipment, how to make sure the products quality?

A:If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker,we will supply you a video for production process detail include process report, products size,structure and surface detail, packing detail and so on, and will provide the inspection report to you.

Q: How to pack the molds and products?

A: 1).For molds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mold, finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q: What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 40% second mold payment before sending out the first trial samples, 20% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q:What is the MOQ ?

A: 100 Pieces for each item, Of course the more the cheaper.

Q: What should we do if we receive defective products?

A: If you receive defective products, please send us photos or videos, we will feed back to our engineers and quality control department, and solve the problem as soon as possible. We are responsible for all products.

A:We will submit the quotation in 24 hours if getting detailed information during working days.In order to quote for you earlier, please provide us the following information together with your inquiry.

1) 3D Step of Files or 2D Drawings

2) Material requirement

3) Surface treatment

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q: How to enjoy the OEM services?

A: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q: How soon can I get samples? And how long is the lead-time for mold?

A: Depending on your specific project,it usually takes 10 to 20 days to get samples.The lead time is 25-35 days. If the molds are very simple and not big size,we can work out within 15 days.

Q5: Before shipment, how to make sure the products quality?

A:If you don't come to our factory and also don't have the third party for inspection, we will be as your inspection worker,we will supply you a video for production process detail include process report, products size,structure and surface detail, packing detail and so on, and will provide the inspection report to you.

Q: How to pack the molds and products?

A: 1).For molds, we will be coated one-layer anti-rust oil first,and then also will be covered thin films on the mold, finally pack into fumigation wooden case.

2).And as to products, we will pack into standard export cartons or as per customer’s request to pack.

Q: What is your payment terms?

A: Mold Payment: 40% deposit by T/T in advance, 40% second mold payment before sending out the first trial samples, 20% mold balance after you agree the final samples.

B:Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Q:What is the MOQ ?

A: 100 Pieces for each item, Of course the more the cheaper.

Q: What should we do if we receive defective products?

A: If you receive defective products, please send us photos or videos, we will feed back to our engineers and quality control department, and solve the problem as soon as possible. We are responsible for all products.

VIEW MORE

YOU MAY LIKE