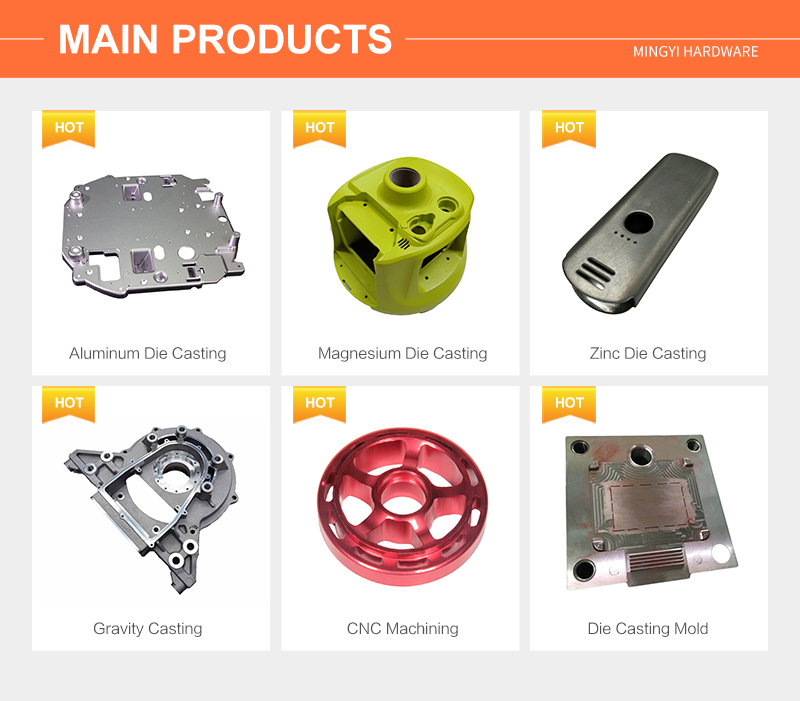

Professional High Quality Customized Magnesium Aluminum Die Casting Zinc Alloy Metal Parts

- $18.50 /piece

- 1 piece

- Dongguan Mingyi Hardware Products Co., Ltd.

- Guangdong, China

- Mr Victor Xu

| color: | custom color | model: | Die-cast metal fittings |

| port: | Shenzhen | Quality Control: | 100% inspection |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Credit card | Supply capacity: | 100,000 pieces of die-cast metal fittings per month |

| process: | Drawing, molding, casting, surface treatment, product testing | place of origin; place of origin: | Guangdong, China |

| Surface treatment: | Spraying/plating/anodizing, etc. | brand: | Die-cast metal fittings |

| Package: | Wooden case, bubble bag, carton and customized | Packaging Details: | Wooden cases, bubble bags, cartons and custom die-cast metal fittings. |

| standard: | ISO9001:2015 | Packaging Preview: | |

| Material: | Zinc alloy | tolerant: | ±0.02mm |

| product name: | Customized Magnesium Aluminum Die Casting Zinc Alloy Metal Fittings | Serve: | OEM\ODM |

Professional High Quality Customized Magnesium Aluminum Die Casting Zinc Alloy Metal Parts

|

Material |

Aluminum alloy:ADC12, ADC10, A360, A380, A356, 6061, 6063 Magnesium alloy AZ91D, AM60B Zinc alloy:ZA3#,ZA5#,ZA8# |

|

Processing technology |

Drawing →make mold→Casting→CNC machining (if required) → surface treatment → product inspection → packaging → delivery |

|

tolerant |

± 0.02mm |

|

surface treatment |

Electroplating, chrome plating, zinc plating, nickel plating, electrophoresis, anodizing, polishing, sandblasting, passivation, powder coating, painting, etc. |

|

quality assurance |

ISO9001:2015 certification, SGS certification |

|

Main Test Facility |

3D measuring instrument(three coordinates),Salt spray test chamber, dynamic balance detector, pneumatic testing |

|

Features and Benefits |

1. High machining accuracy, flatness within 0.1mm. 2. High strength, not easy to deform, with good electrical and thermal conductivity. 3. The surface finish is high, and the surface finish after processing is Ra1.6. 4. The appearance is free of particles, spots and paint peeling. |

|

standard |

ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 |