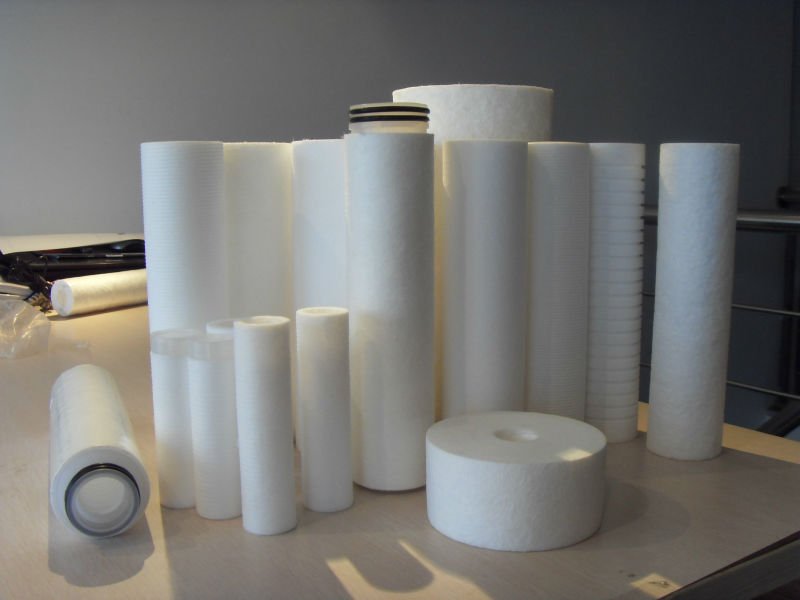

Hot Sale PP Sediment Filter/Melt Blown Filter 30 Inches Length 5 Microns

- $3.00 / 10 - 99 pieces

$0.20 / >=100 pieces - 10 pieces

- Shanghai Minipore Industrial Co., Ltd.

- Shanghai, China

- Mr Jeason Chan

| Supply capacity: | 5,000,000 PP meltblown/spun/sediment filter elements per week | Local service location: | not any |

| Marketing Type: | normal product | Packaging Details: | 25pcs/carton, 50pcs/carton or as customer's request |

| length: | 5'' 10'' 20'' 30'' 40'' | Warranty: | 6 months |

| payment terms: | Western Union, T/T, Paypal | End Adapter: | O-DOE, 7-226fin, 8-222fin, 3-222Flat closed, etc. |

| nuclear: | polypropylene/none | Micron Rating: | 1μm, 2μm, 3μm, 10μm, etc. |

| brand: | microporous or OEM | Applicable industries: | Hotels, clothing stores, building supplies stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, home use, retail, food stores, print shops, construction, energy and mining, food and beverage stores, advertising agencies |

| diameter: | 2.5 inches or 4.5 inches | seal: | Silicone, Viton, EPDM, NBR, etc. |

| Showroom location: | not any | application: | Drinking water treatment, RO+DI pre-filtration, etc. |

| Mechanical test report: | if | aspect: | S(62~65mm) B(110~115mm) |

| Core component warranty: | 1 year | Video shipment inspection: | if |

| product name: | PP meltblown/spun filter element | Origin: | China Shanghai |

| Material: | 100% of polypropylene microfiber | port: | Shanghai |

| Health status: | new | After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Core components: | pressure vessel |

Nominal rated PP meltblown/spun filter element

Features and advantages

A. Surface pore structure disperses water flow to reduce pressure drop

B. Continuous gradient hole structure increases dust holding capacity, longer service life and higher efficiency

C. High strength, pressure resistance

D. Micro denier melt blown filter fiber, high removal rate

E.100% PP, compatible with various process fluids

F. Formed by thermal bonding without using any adhesives and adhesives

High performance pure polypropylene deep dual gradient density filter media is manufactured using a highly controlled process to ensure consistently reproducible filtration performance. Consisting of an internally compact rated section for excellent dirt holding capacity and outstanding performance meeting the highest quality demands, PM series filters are selected for critical filtration applications.

PM Series elements retain contaminants across the entire cross-section of the filter. The density gradually increases from the outer surface to the interior, "graded density" allows larger particles to be trapped near the surface, while smaller particles penetrate the larger open area and are trapped in smaller openings near the center of the filter.

application.

• Drinking water treatment

• RO+DI pre-filtration

• Food and drink

• Plating, chemicals and solvents

Specification

• Material: 100% PP microfiber

• Core: PP/None

• Micron classes: 1, 3, 5, 10 ... 100um

• Outside diameter. 62-65mm/110-115mm; ID. 28mm

• Length: 5", 10", 20", 30", 40", 50", 60"

Operating conditions

• Maximum pressure difference: 3.5bar at 20°C;

2.1bar at 60°C;

1.1bar at 80°C

• Recommended replacement: 1~1.5bar

• Maximum temperature: 80°C

order guide

Model PM | media type | support core | dimension | Micron Rating | end adapter | seal | length |

| PM-1 standard | P-high performance | Polypropylene | S-ID28mm Outer diameter 62~65mm | 0.1:1um | the code | EPDM | 10'' |

| PM-2 slot | A-absolute grade | N - none | B-ID28MM Outer diameter 110~115mm | 0.3:3um | DOE without adapter | n-NBR | 20'' |

| PM-3 wide slot | 0.5:5um | 7-226/fin | S-Silicone | 30'' | |||

10:10um | 8-222/fin | V-Viton | 40'' | ||||

3-222/closed | Viton encapsulated in T-Teflon | ||||||

2-226/closed |

Other Products

-

50/75/100/200/300/400 GPD reverse osmosis RO membrane price for home use$0.50 - $10.00 / piece

50/75/100/200/300/400 GPD reverse osmosis RO membrane price for home use$0.50 - $10.00 / piece