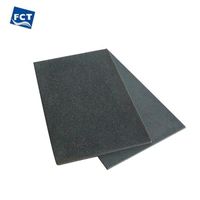

Industrial Boiler Thermal Shock Insulation Refractory Block Thick Plate Lightweight Plate

- $3.00 / >=1000 sets

- 1000 sets

- Shenzhen Bluewind Vermiculite Products Co., Ltd.

- Guangdong, China

- Mr Yusol Cheng

PRODUCT DETAIL

| Packaging Details: | Carton packaging and pallet loading; | CaO content (%): | 1.5-3% |

| sample: | usable | Cold Compression Strength: | 6 MPa |

| Origin: | Hebei china | application: | industrial boiler |

| Supply capacity: | 100000 pieces per month | size: | custom made |

| MgO content (%): | 14-20% | Silicon carbide content (%): | 0 |

| Package preview: | feature: | Thermal shock resistance | |

| Refractoriness (degrees): | Ordinary (1580° | port: | Tianjin harbor |

| brand: | blue wind | Al2O3 content (%): | 13-16% |

| model: | V-1200 | Bulk density: | 900 kg/m3 |

| Fire load (RUL): | 1100°C | color: | sand |

| shape: | jam | payment terms: | L/C, D/P, T/T |

| product name: | vermiculite block | raw material: | Expanded Vermiculite |

| Silica content (%): | 45-48% | CrO content (%): | 0 |

| Material: | Vermiculite | Processing services: | punching, cutting, forming |

Description of Vermiculite Board

feature

heat resistanceup to 1200C

Thermal Conductivity0.18 W/m2

density900 kg/m3

shape: Molded products

Features of condensing gas boiler

no damage

preservative

long lasting

low dimensional tolerance

low cost

no pollutants

high strength

Fire insulation performance

light

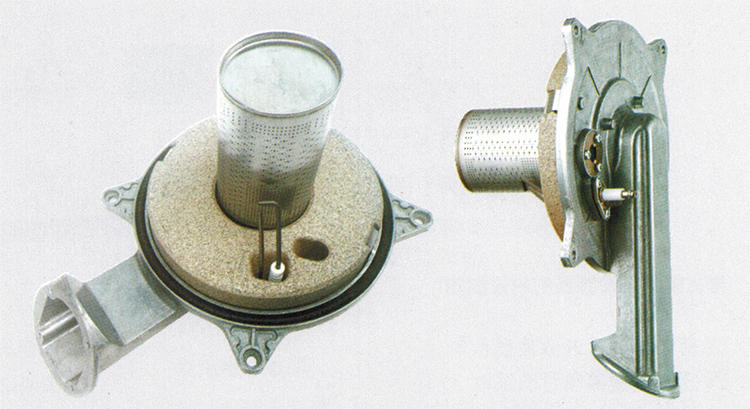

Molded parts

thermal battery

The heat chamber is the heart part of the condensing boiler, which determines the service life of the condensing boiler.The 1200℃ vermiculite board can withstand the environment of extremely rapid drying and water immersion; it has better performance than traditional ceramic fiber board.

condensing boiler

The ideal service life of a condensing boiler is about 12-15 years, and the heat battery at the heart determines whether it can achieve the ideal life. The use of high-quality vermiculite board can reduce the number of hot core replacements and reduce the worries of users.

For use under harsh conditions, vermiculite boards have excellent mechanical strength, good resistance to thermal spalling, and are highly resistant to chemical attack by volatile alkalis and some slags.

detailed drawing

Product parameters

physical parameters | ||||||

Density (kg/m3) | 700 | 800 | 900 | |||

maximum temperature | 1150°C | 1150°C | 1150°C | |||

strength | 4.5/2.0 MPa | 5.5/2.1 MPa | 6.2/2.2 MPa | |||

linear shrinkage | 1% | 1% | 1% | |||

Heat Conduction. | ||||||

@200℃ | 0.14 W/m² | 0.16 W/m² | 0.18 W/m² | |||

@ 400°C | 0.16W/square meter | 0.18 W/m² | 0.2 W/m² | |||

@600℃ | 0.18 W/m² | 0.2 W/m2 | 0.22 W/m² | |||

chemical parameter | ||||||

silica | 43-46% | 43-46% | 45-48% | |||

Aluminum oxide | 10-13% | 10-13% | 13-16% | |||

Ferric oxide | 4-6% | 4-6% | 4-6% | |||

Titanium dioxide | 1-2% | 1-2% | 1-2% | |||

magnesium oxide | 16-23% | 16-23% | 14-20% | |||

potassium oxide | 7-10% | 7-10% | 5-8% | |||

Na2O | 1-2% | 1-2% | 1-2% | |||

LOI @ 1000C | 4-6% | 4-6% | 3-5% | |||

Standard Sizes and Thicknesses | ||||||

1005*615mm | 10-60 mm thickness | 10-60 mm thickness | 10-60 mm thickness | |||

1225*615mm | 10-60 mm thickness | 10-60 mm thickness | 10-60 mm thickness | |||

Data are average results of tests performed under standard procedures and are subject to change.

production process

urgent

High pressure molded to desired shape

drying

Dries to release contained moisture and form a stable application

quality inspection

For each unit, we have one by one inspection to ensure the final use.

Product packaging

VIEW MORE

YOU MAY LIKE