Internal mixer Banbury rubber kneader 35L rubber dispersion kneader Banbury internal mixer

- $10000.00 / 1 - 8 sets

$9000.00 / >=9 sets - 1 set

- Qingdao Chaoguangyue Industry Co., Ltd.

- Shandong, China

- Mr Daguang Qiu

| After Warranty Service: | online support | Showroom location: | United States, Germany, Vietnam, Philippines, Peru, Saudi Arabia, Indonesia, India, Argentina, South Korea, UAE, Colombia, Tajikistan |

| Video outbound inspection: | if | Rotor: | H Chrome plated and polished |

| Applicable industries: | Clothing Stores, Manufacturing Plants, Machinery Repair Shops, Food & Beverage Factories, Farms, Construction Works, Others, Advertising Agencies | Year: | 2023 |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | After-sales service provided: | online support |

| brand: | CGY | Main selling points: | automatic |

| Feeding type: | front and back | Core component warranty: | 3 years |

| port: | Qingdao Port | Batch time (times/hour): | 8 times/hour |

| Weight (kg): | 6500 kg | Advantage 2: | Good sealing, no powder leakage |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | Advantage 1: | preservative |

| Origin: | Shandong Province, China | Health status: | new |

| type: | Rubber kneader | Voltage: | 380 |

| Warranty: | 3 years | Certification: | EU CE certification |

| weight: | 1 ton-22 tons | Supply capacity: | Competitively priced 30 sets per month |

| Mechanical test report: | if | Total capacity (liter): | 35 liters |

| strength: | 1.5kw-75kw | Packaging Details: | In wooden box or as your request |

| Power (kW): | 55 kW |

Internal mixer Banbury rubber kneader 35L rubber dispersion kneader Banbury internal mixer

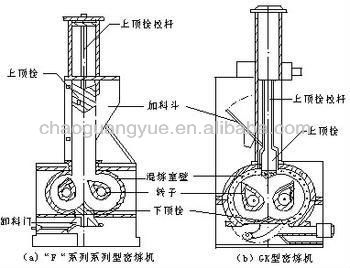

1. Mixing chamber and rotor

2. Side panels and pressure covers

3. Mechanical seal and chamber tilt

4. Electrical control panel

application:

This powerful internal mixer is versatile for mixing and refining raw materials such as raw rubber, synthetic rubber, resins, pitch, cellulose, PVC or EVA into a homogeneous mixture. The machine body and structure are durable and suitable for heavy-duty mixing and refining operations.

feature:

The specially designed dust-proof device can effectively prevent the leakage of raw materials and other components. The product has long service life, simple operation, good effect, convenient maintenance, and easy replacement of wearing parts. It is an ideal mixing equipment for heavy-duty use.

There are two types of discharge doors: hanging doors and sliding doors. This model is a drop door type.

parameter

|

parameter |

Version |

|||

|

X(S)N-35/30 |

X(S)N-55/30 |

X(S)N-75/30 |

X(S)N-110 |

|

|

Chamber net volume (L) |

75 |

125 |

175 |

250 |

|

workload |

35 |

55 |

75 |

110 |

|

Front/rear rotor friction ratio |

1.22 |

1:1.22 |

1:1.22 |

1.22 |

|

Power (kW) |

55 |

75 |

110 |

160 |

|

Main motor speed |

985 |

985 |

985 |

985 |

|

turning angle |

140 |

140 |

140 |

140 |

|

size |

3200*1900*2950 |

3750*1950*3050 |

3760*2143*30500 |

3930*3000*3660 |

|

Weight (kg) |

6500 |

7800 |

10000 |

16000 |

product information:

Thermal resistance:

There is a plug-in thermal resistance in the middle of the bottom of the box, which is connected to the electrical system to detect and display the temperature.

Rotor:

It is designed for Banbury type hollow inserts. The hollow part communicates with the shaft hole of the rotor shaft and is used as a cooling or heating channel. The top edge of the blade and the end face of the rotor shaft are surfacing and ground with cobalt-based carbide, then hard chrome plated and polished.

Cooling/Heating System:

The cooling or heating of materials in the mixing operation adopts a common piping system. With this system, cooling water or steam is delivered in three ways to the cavities of the rotor blades, the mixing chamber and the top plunger.

tilting mechanism:

It is composed of rotor with brake, cycloid reducer, TP type worm, worm gear and so on. Capable of driving the mixing chamber tilted 140° around the front rotor.

Dust seal:

The connection between the top of the mixing chamber and the cantilever of the frame adopts an arc-shaped slot dust-proof sealing component, and the sealing effect is excellent and reliable.

The end face of the rotor is sealed with end face contact, oil-free lubrication, good sealing, wear-resistant and durable.

Packing details: wooden pallet and film packing

Delivery Details: 60 working days from down payment

Other Products

-

High-quality three-roll PVC calender/soft and hard PVC sheet production line$6000.00 / set

High-quality three-roll PVC calender/soft and hard PVC sheet production line$6000.00 / set -

Hydraulic tire drawing machine$820.00 / set

Hydraulic tire drawing machine$820.00 / set -

china manufacture rubber machinery oil seal making machine /rubber vulcanizing machine$100.00 / set

china manufacture rubber machinery oil seal making machine /rubber vulcanizing machine$100.00 / set -

Qingdao Rubber Filter Machine/Rubber Extruder/Rubber Strainer$3000.00 / set

Qingdao Rubber Filter Machine/Rubber Extruder/Rubber Strainer$3000.00 / set