PERFECT LASER - Low Cost Photovoltaic Cell Production Line 350mm 20w Thin Film Solar Cell Cutting Machine

- $12500.00 / 1 - 4 units

$12000.00 / 5 - 9 units

$11500.00 / 10 - 49 units

$8800.00 / >=50 units - 1 unit

- Perfect Laser (Wuhan) Co., Ltd.

- Hubei, China

- Ms Mary JX

| Supported graphic formats: | AI,PLT,DXF,DWG,DXP | Marketing Type: | hot product |

| Laser type: | fiber-optic laser | Origin: | China |

| Core component warranty: | 1 year | Applicable industries: | manufacturing plant |

| Applicable materials: | solar cell | cooling method: | air cooled |

| Weight (kg): | 100 kg | product name: | Silicon wafer dicing |

| Health status: | new | application: | laser scribing |

| Supply capacity: | 5000 silicon wafer scribing and cutting per year | brand: | perfect laser |

| Rail brand: | Shangyin | Workbench width: | 200*200mm |

| Warranty: | 1 year | Laser source brand: | Raycus |

| Video shipment inspection: | if | strength: | 20w 50w |

| payment terms: | L/C, Western Union, T/T, MoneyGram, PayPal, Escrow | controlling software: | Laser Scribe |

| Mechanical test report: | if | Model: | PE-20W/50W |

| Scribing speed: | 240 mm/s | Core components: | laser source |

| brand: | perfect laser | wavelength: | 1064nm |

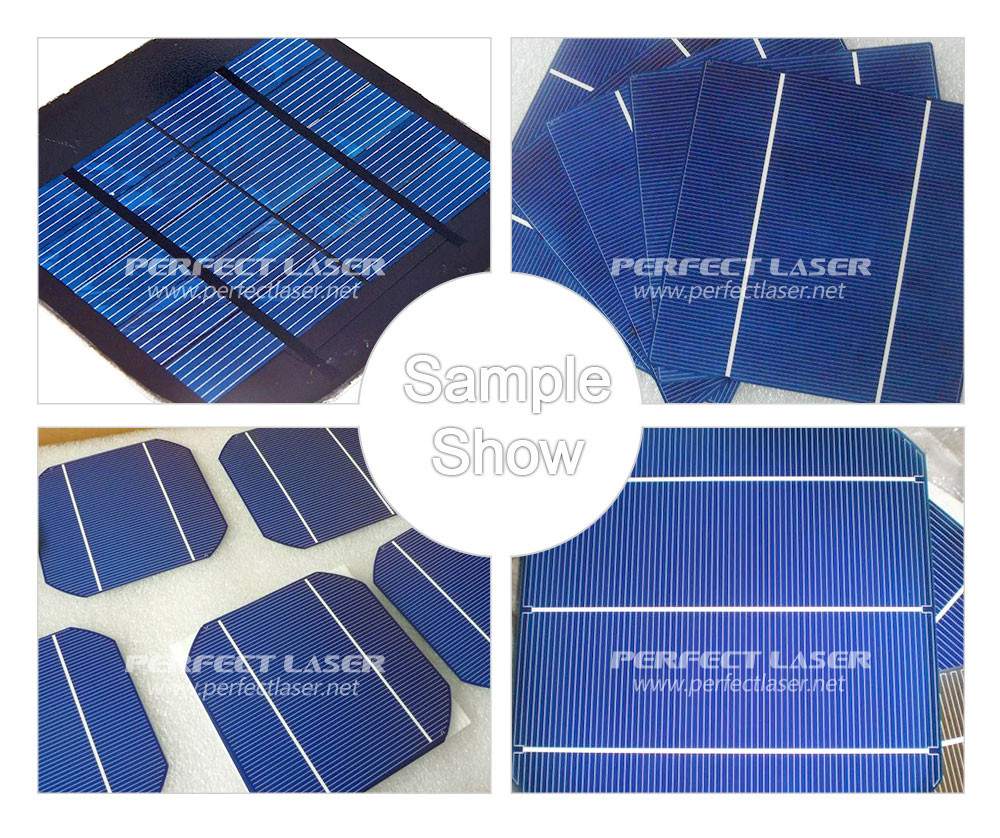

| Cutting material: | Monocrystalline silicon, polycrystalline silicon, amorphous silicon solar cells | Showroom location: | not any |

| port: | Shanghai, Shenzhen, Wuhan | Main selling points: | easy to operate |

| Line Width: | 50um | CNC or not: | Yes |

| Packaging Details: | Seaworthy packaging or seaworthy packaging for dicing and dicing of silicon wafers |

Perfect Laser is a company dedicated to producing laser cutting machines that satisfy customers. ALaser Scribing MachineLaunched model PE-20W/50W. The wafer laser scribing machine reconfigures the workbench processing part, and the open workbench processing area makes loading and unloading more convenient. It is more accurate to disassemble parts from the workbench, and it is not easy to deform. In addition, the laser scribing machine can serve the modification of the laser scribing solar cell motor, with more stable operation, less cutting noise and more humanized design.

1. This solar cellLaser Scribing MachineFully enclosed design with a dust cover to avoid environmental pollution and prevent the operator from being damaged.

2. Software upgrade:The solar cell laser scribing machine supports arc interpolation, making arc cutting smoother.

3. Wafer dicing machine upgrade:After transformation, it takes up less space and the operation is more ergonomic.

4. Restructure the processing part of the workbench, the open workbench processing area makes loading and unloading more convenient. Remove the parts from the flat plate of the workbench, with higher precision and less deformation.

5. Improvement of the screw part of the solar cell laser scribing machine: increase the lead of the screw to speed up the processing speed and ensure the processing accuracy.

6. The in-line optical path design of the solar cell cutting machine has higher processing precision and better effect.

7. Servo motor modification: more stable operation, less cutting noise, and more humanized design;

8. Autocratic plane dust removal device, better processing effect of solar cell cutting machine.

9. The laser signal control part of the solar cell cutting machine has been improved, and the software runs more stably and quickly.

thisFiber Laser Scribing MachineWidely used in the solar photovoltaic industry, the scribing process (cutting section) of monocrystalline silicon and polycrystalline silicon solar cells (cells) and silicon wafers (wafers).

Model Specifications | PE-20W/50W Fiber Laser Scribing Machine | ||

Laser wavelength | 1064nm | ||

laser power | 20W or 50W | ||

Line Width | 50um | ||

Scribing speed | 240 mm/s | ||

Marking accuracy | ±10um | ||

wide workbench | 200×200mm | ||

Temperature control accuracy | 0.5°C | ||

Working power | 220V/50Hhz/1.5KVA | ||

workbench | Battery automatic adsorption, dust removal | ||

cooling method | Professional integration of high-precision constant temperature circulating water cooling | ||