china best lathe cnc controller for cnc lathe or cnc turning

- $800.00 / 1 - 9 sets

$750.00 / 10 - 19 sets

$730.00 / >=20 sets - 1 set

- Wuhan Huazhong Numerical Control Co., Ltd.

- Hebei, China

- Ms Masha Huang

| Showroom Location: | Russia,Thailand; | Place of Origin: | Hubei, China; |

| Interface: | USB+RS232 Communction Port; | Condition: | New; |

| Core Components: | PLC; | Applicable Industries: | Machinery Repair Shops,Manufacturing Plant; |

| Application: | Lathe and Turning Center; | Marketing Type: | Hot Product 2019; |

| COLOR: | Black; | After-sales Service Provided: | Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Online support,Free spare parts; |

| Package Preview: | ; | Selling Units: | Single item; |

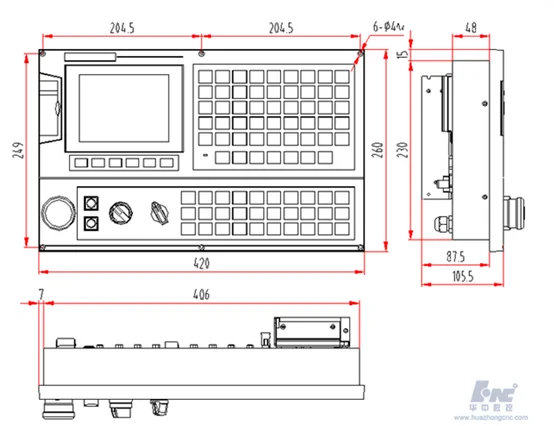

| Axis: | 2-3; | Single package size: | 42X26X12.6 cm; |

| Certification: | ISO, CE; | Local Service Location: | Indonesia,Russia,Thailand,Malaysia; |

| Brand: | HCNC; | Product Name: | HNC808xp; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Warranty: | 1 Year; |

| Power: | DC24V; | Video outgoing-inspection: | Provided; |

| Packaging Detail: | Wooden case or carton box; | Dimension(L*W*H): | 420 x260x126 mm; |

| Single gross weight: | 4.000 KG; | Spindle Control: | Analog; |

| Panel: | Operational Panel; | Brand Name: | HCNC; |

| Machinery Test Report: | Provided; | Weight: | 4KG; |

| Communication mode: | FTP; |

HNC808XP series cnc controller

HNC Electric 808xp system adopts advanced open architecture, built-in Industrial Personal Computer (IPC), 7-inch color LCD display, and standard operation panel. The system integrates the interfaces for feed spindle, spindle, hand-held units, and built-in PLC, USB application reads function, mainly is suitable for the CNC milling machine.

1. 2-3 axis control

2. 7” color LCD screen

3. Supporting pulse protocol

4. Supporting TCP\IP, Ethernet communication protocols

Features of HNC808XP series

1. Providing function for constant small line segment machining, which is suitable for part processing of complicated modules

2. Providing the function for breakpoint save and machining recovery

3. Providing the functions for backlash compensation and single or bi-directional pitch error compensation to improve the machining precision

4. Providing USB interfaces to achieve easy and fast data access

5. Supporting Ethernet functions to achieve fast program and data transmission

6. Providing 400 KB (expandable by using a CF card ) Flash RAM power-off storage and 32 MB RAM buffer

7. Processing breakpoint save/restore function, provide guarantee for user security, ease of use.

8. Providing the functions for backlash compensation and single or bi-directional pitch error compensation to improve the machining precision

9. Providing USB interfaces to achieve easy and fast data access

10. System overall dimensions for: 420 x260x126 mm (H * W * D), small size, solid structure, beautiful appearance.

11. Being compatible with various pulse instruction AC servo drives

12. Configured with switch-value input (32) and output (24) interfaces, hand-held unit interface,

13. Simulation spindle control and encoder interfaces

14. Adopting 7 -inch monochrome or color LCD (resolution: 320 x 240)

15. Providing the functions for identifying faults and reporting alarms, and displaying graphical machining paths, which enables users to easily operate and use the system

16. Adopting international standard G-code programming mode and being compatible with popular CAD or CAM automatic programming systems, and providing functions for linear, circular, and thread interpolation, fixed loop programming, rotation, image resizing, mirroring, tool compensation, and customized macro programming

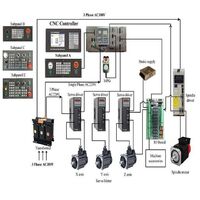

Diagram of CNC Lathe or Milling Connection

HNC808XP 2.0 SMART FUNCTION

Application of HNC808XP series

CNC lathe, machining center, cnc milling

Install dimension of HNC-808XP system