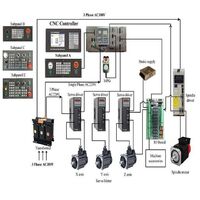

atc lathe CNC controller/3 axis CNC controller kit similar to GSK CNC control system

- $423.00 /set

- 1 set

- Shenzhen Denver Servo Technology Co., Ltd.

- Guangdong, China

- Ms KOKO Deng

PRODUCT DETAIL

| Macro function: | yes | Support hand pulse: | yes |

| port: | Qingdao | Applicable industries: | Building material stores, machinery repair shops, manufacturing plants, construction projects |

| Dimensions (L*W*H): | 425*245*125 | Servo and stepper supported: | yes |

| Core components: | Programmable Controllers | Package preview: | |

| Marketing Type: | normal product | After warranty service: | online support |

| Mechanical test report: | if | Warranty: | 1 year |

| place of origin; place of origin: | Guangdong, China | Video shipment inspection: | if |

| brand: | denver | State of health: | new |

| Packaging Details: | carton | payment terms: | L/C, T/T |

| exhibit: | 8.4 inch color screen | memory: | 56MB |

| axis: | Three axes (X, Z, Y) | PLC function: | yes |

| After-sales service provided: | online support | application: | Lathes and Turning Centers |

| ATC function: | yes | Showroom location: | not any |

| weight: | 10 |

Features

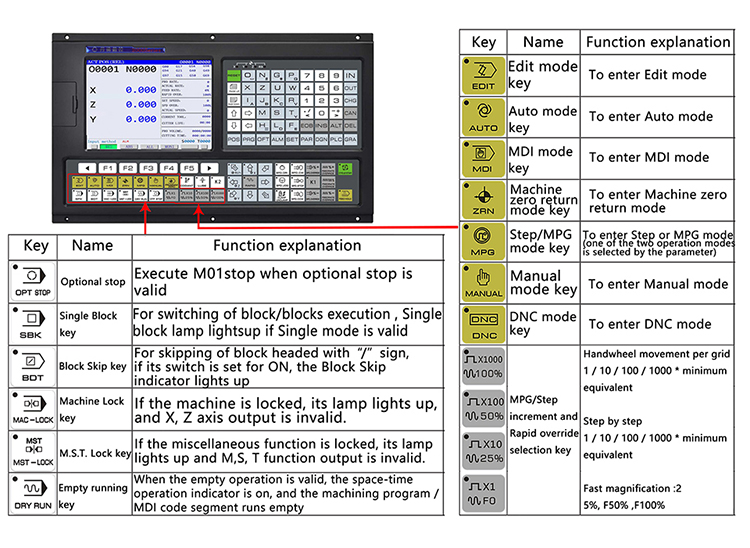

● X, Z, Y, three-axis control, the number of control axes can be customized ● 1ms interpolation cycle, control accuracy 1μm ● Maximum speed 60m/min ● Adaptive servo spindle, which can realize continuous positioning of the spindle, rigid tapping and rigid thread Processing ● Built-in - in multi-PLC program, the currently running PLC program can be selected ● Support statement macro code programming, support macro program call with parameters ● Support metric/inch programming, with automatic tool setting, automatic chamfering, tool life management Functions ● Support Chinese and British English display, parameter selection ● USB interface, support U disk file operation, system configuration and software upgrade ● 2-way 0V ~ 10V analog voltage output, support dual-spindle control ● 1-way handwheel input, support handheld unit ● 36-point universal input / 36-point universal output ● Outline installation dimensions, command system are fully compatible with GSK980TDb

Specifications

Number of control axes | Number of control axes: 3 axes (X, Z, Y) |

Number of linkage axes: 3 axes | |

Feed axis function | Minimum input increment: 0.001mm (0.0001inch) or 0.0001mm (0.00001inch) optional |

Minimum instruction increment: 0.001mm (0.0001inch) or 0.0001mm (0.00001inch) optional | |

Maximum stroke: ±99999999 x minimum command increment | |

Fast moving speed: up to 60m/min | |

Rapid rate: F0, 25%, 50%, 100% four-level real-time adjustment | |

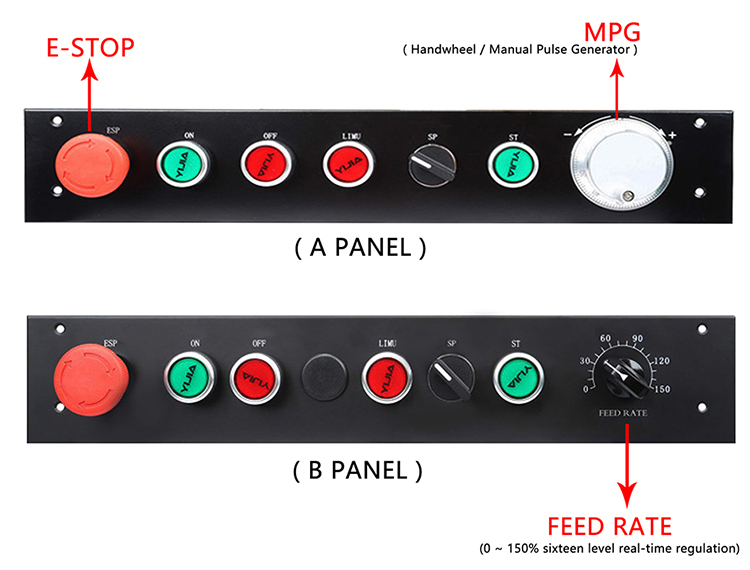

Feed rate: 0~150%, a total of 16 levels of real-time adjustment | |

Interpolation method: linear interpolation, circular interpolation (supports three-point circular interpolation), thread interpolation, rigid tapping | |

Automatic chamfering function | |

thread function | Ordinary thread (following the spindle)/rigid thread |

Single/long external thread Inch straight thread, tapered thread and face thread, constant pitch thread and variable pitch thread | |

The retraction length, angle and speed characteristics can be set | |

Pitch: 0.01mm to 500mm or 0.06 teeth/inch to 2540 teeth/inch | |

Acceleration and deceleration function | Cutting feed: front acceleration and deceleration linear type, front acceleration and deceleration S type, rear acceleration and deceleration linear type, rear acceleration and deceleration exponential type |

Rapid movement: front acceleration and deceleration linear, front acceleration and deceleration S, rear acceleration and deceleration linear, rear acceleration and deceleration exponential | |

Thread cutting: straight line, index optional | |

The starting speed, ending speed and acceleration and deceleration time are set by parameters | |

main function | 2-way 0~10V analog voltage output, support dual-spindle control |

1 channel of spindle encoder feedback, the number of spindle encoder lines can be set (100p/r ~ 5000p/r) | |

Encoder and spindle transmission ratio: (1~255) (1~255) | |

Spindle speed: can be given by S code or PLC signal, speed range 0r/min~9999r/min | |

Spindle override: 50% to 120%, a total of 8 gears for real-time adjustment | |

Spindle constant surface speed control | |

Rigid tapping | |

The role of knives | Tool Length Compensation |

Tool nose radius compensation (C type) | |

Tool Wear Compensation | |

Tool Life Management | |

Tool setting method: fixed point tool setting, trial cutting tool setting, rear reference point tool setting, automatic tool setting | |

Tool setting execution method: modify coordinate method, tool setting method | |

Precision Compensation | backlash compensation |

Memory spacing error compensation | |

PLC function | Second-level PLC program, up to 4700 steps, first-level program refresh cycle 8ms |

PLC program communication download | |

Support PLC warning and PLC alarm | |

Support multiple PLC programs (up to 20), select the currently running PLC program | |

Basic I/O: 36 inputs/36 outputs | |

HMI | 8.4 inches 800×480 resolution widescreen LCD |

Chinese, English and other languages display | |

2D toolpath display | |

Real Time Clock | |

Operation management | Operation mode: edit, automatic, input, machine zero return, hand wheel/single step, manual, program zero return |

Multi-level operation authority management | |

alarm log | |

program to edit | Program capacity: 56MB, 400 programs (including subroutines and macro programs) |

Editing function: program/block/word search, modify, delete, copy, paste | |

Program format: ISO code, support statement macro code programming, support relative coordinates, absolute coordinates and mixed coordinates programming | |

Program call: support macro program call with parameters, 4 levels of nested subroutines | |

communication function | RS232: Two-way transmission of parts programs, parameters and other files, supporting serial port upgrade of PLC programs and system software |

USB: U disk file operation, support PLC program, system software U disk upgrade | |

security features | emergency stop |

hardware travel limit | |

software stroke check | |

Data backup and recovery |

Product Description

Applications

VIEW MORE

YOU MAY LIKE

Other Products

-

Milling Machine Controller CNC System Machine Tool Machining Center Operation Panel FAGOR 8037M$499.00 / piece

Milling Machine Controller CNC System Machine Tool Machining Center Operation Panel FAGOR 8037M$499.00 / piece -

GSK RB06-900 Guangzhou CNC Robot Handling Industry General Robot Arm$99.00 / piece

GSK RB06-900 Guangzhou CNC Robot Handling Industry General Robot Arm$99.00 / piece -

9512 Desktop Small Drilling and Milling Machine Multifunctional Machine Manual Vertical Milling Machine$99.00 / piece

9512 Desktop Small Drilling and Milling Machine Multifunctional Machine Manual Vertical Milling Machine$99.00 / piece -

HEIDENHAIN CNC Controller TNC 620 Machine Tools iTNC530 CNC System$99.00 / piece

HEIDENHAIN CNC Controller TNC 620 Machine Tools iTNC530 CNC System$99.00 / piece