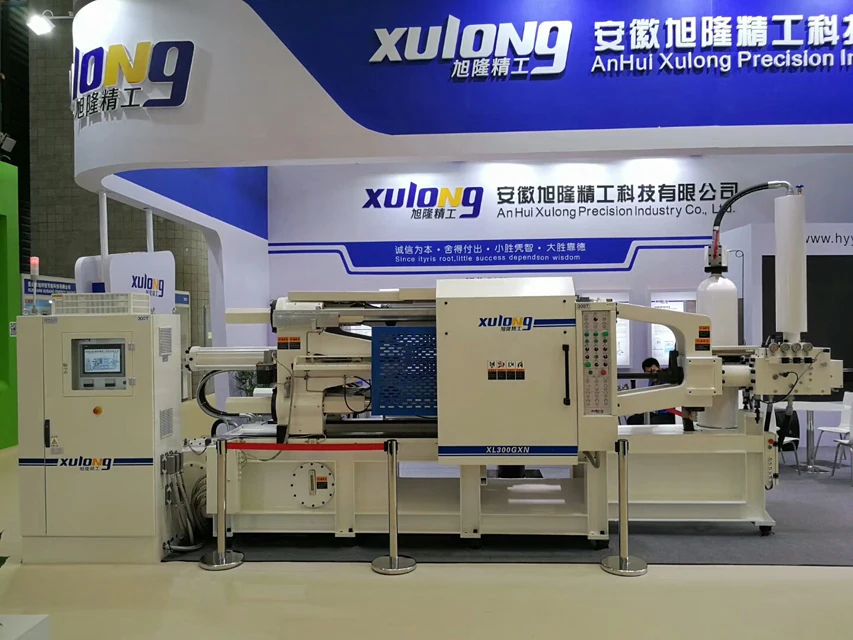

high performance die casting machine adopts the latest structure of the top die casting machine

- $66000.00 /piece

- 1 piece

- Anhui Xulong Precision Industry Co., Ltd.

- Anhui, China

- Mr Juncheng Wang

PRODUCT DETAIL

| Ejection Force(kN): | 180 kN; | Certification: | ISO; |

| Warranty of core components: | 1 Year; | Diameter of Bars(mm): | 110 mm; |

| Open Stroke(mm): | 450 mm; | Casting Stroke(mm): | 410 mm; |

| Max.Thickness of Die Block (mm): | 650 mm; | Place of Origin: | Anhui, China; |

| Port: | china port; | After Warranty Service: | Video technical support,Online support; |

| Voltage: | 380; | Condition: | New; |

| Machine Type: | XL300GXN,Cold Chamber Die Casting Machine; | Customer feedback: | Excellent; |

| Video outgoing-inspection: | Provided; | Min.Thickness of Die Block (mm): | 250 mm; |

| Casting Force(kN): | 320 kN; | Local Service Location: | None; |

| Space between Tie Bars(mm): | 580x580; | Warranty: | 1 Year; |

| Year: | 2020; | Applicable Industries: | Energy & Mining,Home Use,Printing Shops,Food & Beverage Shops,Hotels,Food & Beverage Factory,Retail,Farms,Garment Shops,Restaurant,Building Material Shops,Advertising Company,Machinery Repair Shops; |

| Brand Name: | xulong; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| PLC: | Omron; | Dimension(L*W*H): | 5900x1500x2740; |

| Packaging Detail: | Standard package or as customer requirements; | Application: | Aluminum Alloy Casting; |

| Ejection Stroke(mm): | 100 mm; | Chamber: | Cold Chamber Die Castng Machine; |

| Key Selling Points: | High Productivity; | Showroom Location: | None; |

| Color: | White; | Clamping Force (kN): | 3000 kN; |

| Power (kW): | 22; | Casting Pressure(MPa): | 83 MPa; |

| Hydraulic Valve: | Yuken; | Core Components: | PLC,Bearing,Motor,Pressure vessel,Gear,Pump; |

| Machinery Test Report: | Provided; | Weight (KG): | 8500; |

| Final products: | Alumnium Alloy Castings; | Marketing Type: | New Product 2020; |

| Usage 2: | coppery; | Supply Ability: | 2 Pieces per Month; |

| After-sales Service Provided: | Online support,Video technical support; | Valve: | Yuken; |

Product Description

Xulong Die Casting Machine

* High performance: the maximum air injection speed ≥8M/S,pressurized construction time ≤15MS

* High reliability: According to the latest structure and manufacturing process design of the famous foreign die casting machine factories, the injection system, the heart part of a die casting machine, is capable of various harsh working conditions to achieve high stability and precision production because of its high rigidity, high reliability and high durability.

* High-speed production:According to the new structure design of the most advanced die casting machine made by foreign famous factories, the reliable of high reliable injection system and express clamping system can be greatly improved than traditional die casting machine, and it can realize high-speed production, which can increase the quantity by more than 15%.

* High reliability: According to the latest structure and manufacturing process design of the famous foreign die casting machine factories, the injection system, the heart part of a die casting machine, is capable of various harsh working conditions to achieve high stability and precision production because of its high rigidity, high reliability and high durability.

* High-speed production:According to the new structure design of the most advanced die casting machine made by foreign famous factories, the reliable of high reliable injection system and express clamping system can be greatly improved than traditional die casting machine, and it can realize high-speed production, which can increase the quantity by more than 15%.

XL300GXNT Cold Chamber Die Casting Machine | ||||||||

Project | Unit | Technical Parameter | ||||||

die locking force | KN | ≥3000 | ||||||

space between tie bars | MM | 580x580 | ||||||

tie bar diameter | MM | φ110 | ||||||

locking stroke | MM | ≥450 | ||||||

die thickness | MM | 250~650 | ||||||

ejection stroke | MM | ≥100 | ||||||

ejection force | KN | ≥180 | ||||||

injection force | KN | 125-320 | ||||||

injection position(0 as the center) | MM | 160 | ||||||

plunger diameter | MM | φ50 | φ60 | φ70 | ||||

injection weight(Aluminum) | KG | 1.4 | 2.1 | 2.8 | ||||

injection pressures | Mpa | 163 | 113 | 83 | ||||

cast projection area | CM² | 183 | 264 | 359 | ||||

max cast projection area | CM² | 750 | ||||||

height of pressure chamber flange | MM | 12-0.05 | ||||||

plunger penetration | MM | ≥155 | ||||||

injection stroke | MM | ≥410 | ||||||

dry cycle | S | 4.3 | ||||||

system working pressure | Mpa | 16 | ||||||

motor power | KW | 22 | ||||||

machine weight | KG | 8500 | ||||||

machine dimension(LxWxH) | MM | 5900X1500X2740 | ||||||

our die casting machines are widely used in auto industry,motorcycles,electro mobiles,toys,home appliances,electronics,gifts,sanitray ware,IT,aviation fileds,etc.

Detail Images:

Products Features:

* Oil hydraulic system adopts proportional controlled system pressure and flow, achieves multi-stage pressure & speed control, and low pressure die clamping protection function.

* Injection speed and pressure are controlled by four stages, position and location are the two ways to supercharge.

* High-speed casting template ,high tension alloy steel Corinth column(tie bars),electroplated chrome outer layer.

* Adopt Omron PLC control system(touch screen) to make sure cast product data storage and monitor capabilities, timely alarm in case of abnormality, and eliminate larger quantities of defective products.

* Adopt Omron PLC control system(touch screen) to make sure cast product data storage and monitor capabilities, timely alarm in case of abnormality, and eliminate larger quantities of defective products.

* Omron PLC control system(touch screen) is powerful, stale and reliable operation.

* Hydraulic driver gear die regulating device.

* Reliable and durable foreign brand electrical appliances and hydraulic components.

* Central electric lubrication system.

* Rapid hydraulic ejecting device and core puller.

Company Description

Anhui Xulong Precision Industry Co,.Ltd is a professional manufacturer,specialized in manufacturing various types die casting machine.In the past 35 years,our products are welcomed by many customer from all over the countries,and earned good reputation in dosmetic and overseas market beuause of advanced manufacturing technology,strict quality control,perfect quality management system and our creative spirit.

Our Office

Workshop & Warehouse

Package &Shipping

Customer Visit

Certifications

Product Applications

LED Lamp Shell

LED Street Lamp Radiator

Lamp

Furniture Part

Cooker

Gas Appliance Parts

Mobile Phone Shell

Mobile Phone Accessories

Motor Head Cover

PAD Shell

Communications Accessories

Projector Shell

VIEW MORE

YOU MAY LIKE