high speed robotic picking and packing delta robot

- $15000.00 /set

- 1 set

- Robotphoenix LLC

- Shandong, China

- Mr Jimmy Zhang

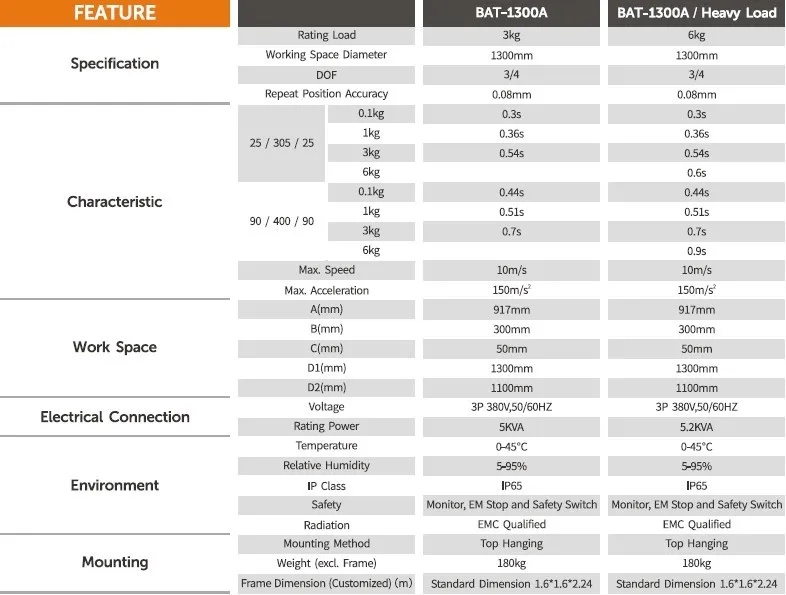

| Supply Ability: | 200 Set/Sets per Month; | gripping model: | single/double; |

| singular accuracy: | ±3°; | Power: | 10KW; |

| Features: | full automatic robot; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Port: | Qingdao/Shanghai/Shenzhen/Beijing; | Certification: | CE,ISO; |

| Warranty: | 1 Year; | storage: | 200/600 pics; |

| spraying method: | direct; | Voltage: | 220V/380V; |

| Application: | food/medical/3C; | Payment Terms: | T/T,Western Union; |

| Brand Name: | RobotPhoenix; | power voltage: | 220V/380V; |

| applicable lid types: | customized; | speed: | 100-120 pics/min.; |

| Packaging Detail: | rectangle wooden box with double layers Styrofoam package; | positioning accuracy: | ±0.1mm; |

| minimal air flow: | 60L/min.; | Dimension(L*W*H): | 4.9x1.4x1.4; |

| Package Preview: | ; | Place of Origin: | Shandong China; |

| labeling speed: | 120 pics/min.; | Production Capacity: | 200/600; |

RobotPhoenix Delta Robot

BAT Robot is perfectly integrated with technologies of robot control, visual recognition and conveyor tracking. It can/accurately track the speed of the conveyor belt and recognize the object's position, color, Shape and size through intelligent visual system. It also can perform packing, /sorting, arrangement and other works as particularly required. Owing to its characteristics of fast and flexible, BAT Robot greatly improves the efficiency of production line and reduce the operation cost of enterprise.

1. High Speed

BAT Robot adopts high response servo drive system and highly optimized transmission structure, and also combines the special control system for robot developed by Robotphoenix, which greatly improves the speed and acceleration of motion. Under the standard stroke, the robot working speed can reach within 0.3s, fully meeting the demands of high-speed production.

2. Heavy Load

BAT Robot can carry objects more than 10kg.

3. Multi-robot Cooperation

Each control system can support up to 12 axis (3 parallel robots). through the internal communication to share information. Multiple machines can share the same set of visual system

4. High Accuracy

The repeated positioning accuracy can reach 0.08mm, very suitable for high precision work.

5. Small Area Coverage with Large - Working Space

BAT-1100, with an area of only 1.4m*1.4m, has a working space of a cylinder with 1100mm diameter and 250mm height.

6. Modular Structure Design

The robot structure adopts modular design, which is convenient for maintenance. Its quick change grab mechanism makes the product line transform easily and quickly.

7. Integrated Control System

The controller of BAT Series is not only a motion controller, but also a machine cotrol system which integrates visual processing and belt tracking; motion control module is in charge of processing and motion controlling algorithms of machine kinematics, path planning and others; visual module includes vision calibration, template matching and image processing; tracking module matches visual processing results with external transport line operation, to perform dynamic tracking and achieve seamless converting between machine and vision.

8. Zero Grad Oil-free

With characteristics of zero grade oil-free, clean and pollution- free, it can provide clean robots for food, pharmaceutical and high precision electronic industries to meet the production requirements of various industries.

Robot Phoenix LLC, founded in 2012, is a robotics company headquartered in Jinan, China, with branches located in Shenzhen, Shanghai. As the market leader for industrial automation in China, our products and services include high-performance industrial robot development, turn-key industrial automation systems, equipment manufacturing, robotics and computer vision system development and all related services. Our flagship product-BAT series robots-have been widely used in food, pharmaceutical, photovoltaic, electronics, daily chemical and logistics industries, to reduce cost in sorting, handling, packaging, coating, palleting, etc.. The standard machine--wet wipe lid application machine, after years experience in this field, takes the largest domestic market share in the market up to today. Robotphoenix's experienced research and development team are here to provide our customers with top-quality and affordable industrial automation solutions and services.