300TPD CIL plant gold leaching tank beneficiation project EPC mining service plant

- $11500.00 /set

- 1 set

- Jiangxi Hengchang Mining Machinery Manufacturing Co., Ltd.

- Jiangxi, China

- Ms Bella Chen

PRODUCT DETAIL

| Video outbound inspection: | if | Certification: | ISO9001 |

| Sales unit: | single product | Motor type: | AC motor |

| After-sales service provided: | online support | application: | Cyanide Leaching Tank |

| Showroom location: | not any | Marketing Type: | normal product |

| type: | Leach tank | Mechanical test report: | if |

| Install: | Technical support | Warranty: | 1 year |

| brand: | Hengchang | Dimensions (L*W*H): | depends on model |

| Packaging Details: | For wet mills shipped by FCL or LCL | Single pack size: | 120X120X25 cm |

| Production capacity: | depends on model | Material: | Carbon steel |

| Key words: | Agitated leaching tank | Core components: | engine |

| Local service locations: | not any | Core component warranty: | 1 year |

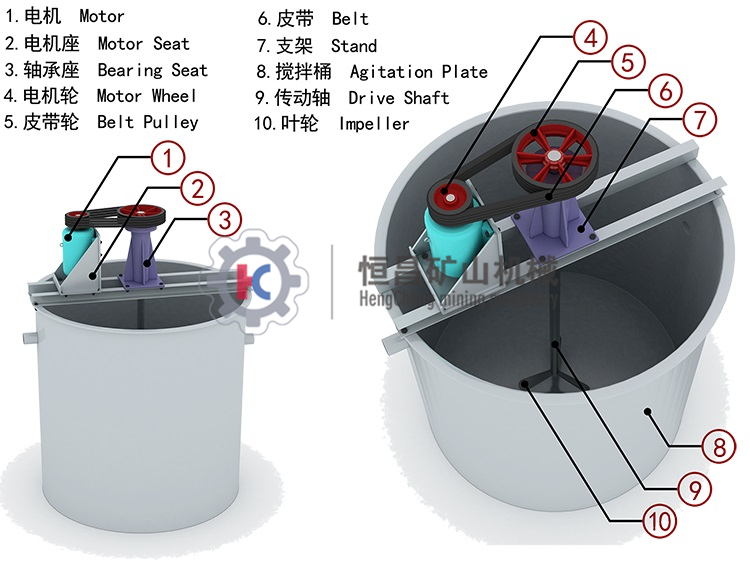

| product name: | Gold stirring double impeller leaching tank | Applicable industries: | Energy and Mining |

| Gross weight per piece: | 5000.000 kg | Function: | uniform feeding |

| usage: | CIL process equipment | Origin: | China |

| Health status: | new |

300TPD CIL plant gold leaching tank beneficiation project brief mine EPC service factory

The gold CIL process (carbon leaching) is an efficient method for the extraction and recovery of gold from ore. The CIL process reduces gold mining operating costs and increases gold recovery to 99% by simultaneously cyaniding and carbon leaching crushed gold slurry. It is the first choice equipment for modern gold mining and gold beneficiation plants.300TPD CIL plant gold leaching tank beneficiation project EPC mining service plant- -Flow Description:

1. After the crushing and grinding stage, 9 levels of high-efficiency cyanide leaching tanks are added to the pulp. The cyanidation of gold paste is carried out in the first two leaching tanks, and the countercurrent adsorption operation is carried out in the last six or seven leaching tanks. Compared with the gold CIP process and other traditional gold extraction processes, the gold CIL process greatly shortens the cyanidation time and reduces the backlog of funds in the gold retention stage. Taking a gold cyanide plant with a processing capacity of 100,000 tons and a gold grade of 7.5 g/t as an example, the gold CIL process can save investment costs of 486,000 US dollars compared with the CIP process, reduce the capital backlog of 201,700 US dollars, and save and recover funds of 675,100 US dollars in advance. Activated charcoal cost not included.

2. In the step of adding activated carbon, the coconut shell activated carbon (small pores, high activity, wear-resistant, renewable) specially selected by Hengchang Mineral Processing Design Institute is added to the pulp, which can dissolve and absorb gold and silver ions Adsorption features form gold-loaded carbons.

3. The vibrating screen and dewatering screen are the key equipment for the reverse movement of pulp and charcoal. The filter press and high-frequency dewatering screen developed by Hengchang can effectively reduce the

Carbon wear on the vibrating screen surface and continuous pumping process reduces cost and facilitates maintenance and operation.

Carbon wear on the vibrating screen surface and continuous pumping process reduces cost and facilitates maintenance and operation.

4. Hengchang desorption electrolysis system conducts high-temperature desorption and electrolysis of gold in gold-loaded carbon through a mixture of sodium cyanide and sodium hydroxide. After the sawdust and other sundries are removed by the washing machine, gold desorption is carried out by Xinhai high temperature and high pressure desorption method (150 degrees, 0.5Mpa), and 99% of gold can be decomposed within 2-6 hours.

Application of leaching tank: CIL is mainly suitable for processing gold ore with a grade above 1g/t and gold ore with large ore content: silver, platinum, copper, etc. CIL has better performance when extracting these minerals at the same time.

Model | Tank specification (mm) | Effective volume (m3) | Impeller revolution(r/min) | Power (kW) | Weight (kg) |

SJ2.0X2.5 | 2000X2500 | 7.07 | 52 | 2.2 | 2144 |

SJ2.5X2.5 | 2500X2500 | 10.8 | 43 | 4 | 2729 |

SJ2.5X3.15 | 2500X3150 | 13.92 | 52 | 2.2 | 3095 |

SJ3.0X3.0 | 3000X3000 | 19 | 43 | 4 | 4583 |

SJ3X3.15 | 3000X3150 | 20 | 43 | 4 | 4160.6 |

SJ3X3.5 | 3000X3500 | 22.97 | 43 | 4 | 4334.6 |

SJ3.15X3.55 | 3150X3550 | 25.73 | 43 | 4 | 4322.8 |

SJ3.5X3.5 | 3500X3500 | 31.3 | 52 | 5.5 | 5025 |

SJ3.5X4 | 3500X4000 | 35.6 | 52 | 5.5 | 5429 |

SJ3.55X4.0 | 3550X4000 | 36.8 | 43 | 4 | 5025 |

SJ3.7X4.2 | 3700X4200 | 42 | 42 | 4 | 6153 |

SJ4.0X4.5 | 4000×4500 | 52.78 | 35 | 7.5 | 7569 |

SJ4.0X6 | 4000×6000 | 71 | 33 | 11 | 9200 |

SJ4.5X5.0 | 4500×5000 | 74.75 | 35 | 7.5 | 10864 |

SJ5.0X5.6 | 5000X5600 | 104.5 | 31 | 11 | 14291 |

SJ5.5X6.0 | 5500X6000 | 135.42 | 31 | 11 | 18745 |

SJ6.5X7.0 | 6500X7000 | 215 | twenty one | twenty two | 25978 |

SJ7.0X7.5 | 7000×7500 | 269 | twenty one | twenty two | 29030 |

SJ7.5X8.0 | 7500X8000 | Chapter 331 | twenty three | twenty two | 32796 |

SJ8.0X8.5 | 8000X8500 | Chapter 402 | 18.5 | 30 | 42467.3 |

SJ8.5X9.0 | 8500X9000 | Chapter 480 | 18.5 | 30 | 46623 |

VIEW MORE

YOU MAY LIKE