Mine Sludge Agitating Tank Mixing Tank Mineral agitation barrels

- $699.90 /set

- 1 set

- Henan Xingyang Mining Machinery Manufactory

- Henan, China

- Mr Andy Zhang

PRODUCT DETAIL

| After sale Service: | 7*24hours; | Warranty: | 1 Year; |

| Supply Ability: | 30 Sets per Week; | Delivery Time: | 15-30 Days; |

| Machinery Test Report: | Provided; | Applicable Industries: | Building Material Shops,Construction works ,Energy & Mining,Advertising Company; |

| Motor Type: | AC Motor; | Video outgoing-inspection: | Provided; |

| Type: | Leaching Tank; | Brand Name: | XKJ; |

| Color: | Customizable; | Diameter: | 50-3550; |

| Online Service Time: | 24 Hours Online; | Core Components: | Engine,Gearbox,Motor; |

| Marketing Type: | Hot Product 2021; | Effective Volume (m3): | 0.33-30; |

| Dimension(L*W*H): | 1354x1310x1742; | Certification: | SIO,CE; |

| Place of Origin: | Henan, China; | Warranty of core components: | 1 Year; |

| Quality: | Advanced Technology; | Packaging Detail: | packagging in one wooden or a container; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Showroom Location: | Turkey,Brazil,Pakistan,Argentina,Bangladesh,South Africa,Japan; |

| After-sales Service Provided: | Free spare parts,Video technical support,Field installation, commissioning and training,Field maintenance and repair service; | Package Preview: | ; |

| Factory visit: | Welcomed Warmly; | Port: | Qingdao,Shanghai,Tianjin; |

| Condition: | New; | Spare parts supply: | Anytime; |

| Price: | Negotation; | Local Service Location: | Italy,Philippines,India,Malaysia,Kenya,Romania,Kazakhstan,Ukraine; |

Product Description

Mineral agitation barrels — Product Description

[Introduction]:

Mineral agitation barrels of the necessary equipment that dynamic Vbelt of motor drive rotating impeller will be mixed full of drugs and pulp evenly, increasing reaction time, strengthen the role of pharmaceutical drug reactions quality, the machine applies

to election mining, the chemical industry also can be used as mixing ingredients. It used the density of less than 30% and frozen composition of less than 1mm, and the formation is flatbottom barrel radiation with circle cross collar of mechanical mixing.

to election mining, the chemical industry also can be used as mixing ingredients. It used the density of less than 30% and frozen composition of less than 1mm, and the formation is flatbottom barrel radiation with circle cross collar of mechanical mixing.

Advantage

Mineral agitation barrels—Advantage

1.Diameter of impeller is increased, so the peripheral speed of the impeller is increased, agitating ability to pulp and chemical is improved.

2.The impeller is the designed into a pileus type, agitating and cycling ability to pulp and chemicals is improved

3.There equipped with a duck and the impeller is in it. The improvedment of the agitation ability increased the negative pressure caused by slurry movement, which is confined to a limited space by the duct, reinforcing the sucking ability for slurry and chemical and further strengthening the cycling effect of the slurry and chemical

4.The pileus impeller products a downward pressure during running, so that the sucking force is reinforced again, and then the cycling effect of the slurry and chemical is strengthened as well .

5. Beneath the duct, jets are arrrangen, which is also helpful to the cycling. Complete agitation and cycling of the slurry and chemical have the mineral surface to be fully contacted with chemical, being benefit to flotation. Only mineral surface is 100% reagent-contacted, high recovery is guaranteed.

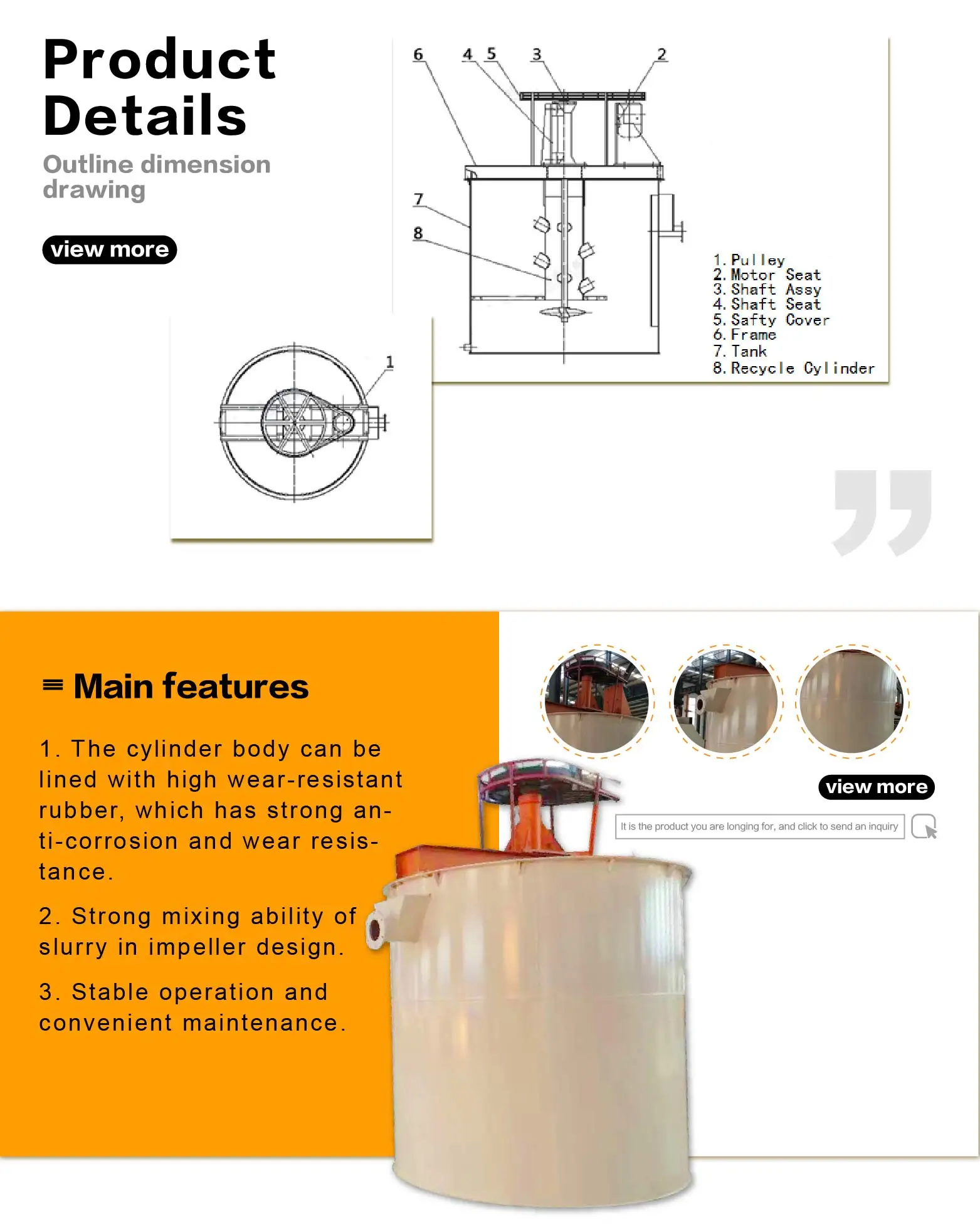

Product Details

Products Specifications

Standard Model | XB-500 | XB-1000 | XB-1500 | XB-2000 | XB-2500 | XB-3000 | ||

Effective Volume(m3) | 0.124 | 0.58 | 2.2 | 5.46 | 11.2 | 19.1 | ||

Impeller | Diameter(mm) | 150 | 240 | 400 | 550 | 650 | 700 | |

Speed(r/min) | 1000 | 530 | 320 | 230 | 280 | 210 | ||

Motor | Model | Y100L-4 | Y132S-6 | 132M-6 | Y160M-6 | 180L-6 | Y225S-8 | |

Power(kw) | 1.5 | 3 | 5.5 | 7.5 | 15 | 18.5 | ||

Internal Size of Trough | Diameter(mm) | Φ500 | Φ1000 | Φ1500 | Φ2000 | Φ2500 | Φ3000 | |

Height(mm) | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | ||

Dimensions | Length (mm) | 670 | 1130 | 1750 | 2380 | 3028 | 3610 | |

Width(mm) | 351 | 1130 | 1642 | 2162 | 2640 | 3266 | ||

Height(mm) | 1286 | 1491 | 2186 | 2846 | 3543 | 4326 | ||

Weight(t) | 0.375 | 0.685 | 1.2 | 1.65 | 3.462 | 4.292 | ||

Working Principle

Mineral agitation barrels Working principle

The main structure of the wheel gearing is composed of fixed roll, movable roll, drive shaft, machine box, chassis, cover piece, and long gear cover. The motive power of the machine comes from the V-belt pulley of the electromotor, and a pair of middle

reduction gear will make the fixed roll rotate, and then a pair of long gear drive on the other side of the fixed roll will drive the movable roll, and the two rolls perform relative movement to squeeze the materials..

reduction gear will make the fixed roll rotate, and then a pair of long gear drive on the other side of the fixed roll will drive the movable roll, and the two rolls perform relative movement to squeeze the materials..

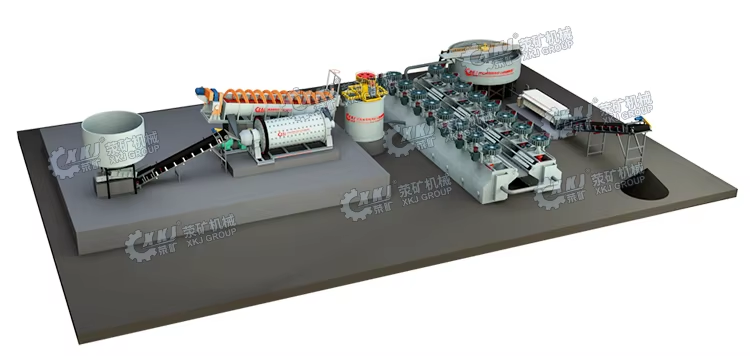

Similar Products

Click the picture to enter the product page!!!

Ball Mill

The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fire-proof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc.

Spiral Classifier

Spiral Classifier can clean and separate the soil and impurities in sand and stone. Its novel sealing structure, adjustable overflow weir plate reliable transmission device ensure the effect of cleaning and dehydration.

SF Flotation Machine

SF flotation cell is a mechanical agitation type flotation equipment with self-slurry suction and self-air suction

Company Information

Company Information:

Why choose us ?

1.We are real manufacture factory ( not dealer)

All machineries from Henan Xingyang Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service; So please buy machine from factory.

2. With senior engineers for research and development.

3. We’d like to recommend a suitable type for you and send you a best quotation.If you are new for this business, we will help you.

All machineries from Henan Xingyang Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service; So please buy machine from factory.

2. With senior engineers for research and development.

3. We’d like to recommend a suitable type for you and send you a best quotation.If you are new for this business, we will help you.

Services

Our Services:

Before-sale services:

We guide customers to choose the best and applicable device; provide the advanced, energy-saving and practical technological processes, as well as we are responsible for the planning and design of the site.

Sale services:

Products must be inspected strictly before being sold; customers are invited to simulate and test machine on-the-spot and raise objections; in accordance with the agreements stipulated in the contract, we will arrange delivery.

After-sale services:

Our Company will send professional engineers to guide device installation, debug and train operators until customers are fully satisfied. Moreover, we will design and produce machines according to the special requirements of customers.

Solemn Promise:

The quality guarantee period of machines is one year except the wearing parts

Tips: The prices in the web only to be reference, according to raw material's price fluctuations; Specific price is subject to the negotiation.

Packing:

Normally the machines are taken apart before delivery and are packed by suitable packing ways, the packing ways are as below: Nude packing. Bundle packing. Grass rope packing. Water proof packing. Wooden pallets packing. Wooden box or carton box packing.

FAQ:

Q How about the quality of your products?

A Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

A Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q How about the price?

A As a manufactory, we can give you lower price than trade companies. Besides, customers from Alibaba can get a discount.

Q Do you provide after-sale service?

A Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q Do you provide equipment operation training?

A Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.

Q Can you test our samples?

A Yes. You can send your samples to us for test and analysis.

Q Can we visit your factory?

A Yes. You can visit our factory anytime you want.

For more details and Video, please contact us by following contact information:

Contact Person: Blake Liu

Whatsapp Number: +8617633803881(phone number as well).

A As a manufactory, we can give you lower price than trade companies. Besides, customers from Alibaba can get a discount.

Q Do you provide after-sale service?

A Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q Do you provide equipment operation training?

A Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.

Q Can you test our samples?

A Yes. You can send your samples to us for test and analysis.

Q Can we visit your factory?

A Yes. You can visit our factory anytime you want.

For more details and Video, please contact us by following contact information:

Contact Person: Blake Liu

Whatsapp Number: +8617633803881(phone number as well).

VIEW MORE

YOU MAY LIKE