80T Drill Pipe Friction Welding Horizontal Friction Welding Machine

- $150000.00 /set

- 1 set

- Jiangsu Kidea Industry Co., Ltd.

- Jiangsu, China

- Mr Kevin Zhu

PRODUCT DETAIL

| aspect: | 5300*2800*2200 mm | Health status: | new |

| Warranty: | 1 year | Rated Duty Cycle: | 100% |

| usage: | welding | Host size (L*W*H): | 5300*2800*2200 mm |

| type: | Friction Welder | Core components: | PLC, bearing, motor, pressure vessel |

| Showroom location: | not any | Mechanical test report: | Not available |

| Maximum flipping force: | 500/600/800 kN | Supply capacity: | 10 sets per month |

| After Warranty Service: | Online support, spare parts, on-site maintenance and repair services | Rotating speed: | 800 rpm |

| Video external inspection: | if | Packaging Details: | - Export Standard Packing: Packing film in wooden case - also according to your request |

| port: | Shanghai | Weight (kg): | 10000kg |

| Marketing Type: | New Products 2020 | Local service location: | not any |

| Model: | C-80 | Oil pump motor: | 37KW |

| Core Components Warranty: | 1 year | Welding Diameter: | 50-80 mm |

| Main motor: | 55/75 kW | Maximum working stroke: | 400 mm |

| Voltage: | 380V / 440V | Main selling point: | Cost-effective |

| Packaging Preview: | After-sales service provided: | On-site installation and commissioning training, online support | |

| brand: | Kija | Rotary clamp clamping length: | 100-380 mm |

| payment terms: | letter of credit, wire transfer | current: | 50A |

| Applicable industries: | Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Construction Engineering, Energy & Mining, Aircraft/Aerospace | Mobile fixture clamping length: | 250mm - Unlimited |

| place of origin; place of origin: | China |

Product parameters

product name | KIDEA C-80 Friction Welder |

Maximum upsetting force | 800 kN |

Welding diameter | 50-80 mm |

Rotary clamp clamping length | 100-380 mm |

Mobile clamp clamping length | 250mm - Unlimited |

Maximum working stroke | 4300 mm |

Rotating speed | 800 rpm |

main motor | 55/75 kW |

Oil pump motor | 37kW |

Host size (L*W*H) | 5300*2800*2200 mm |

Hydraulic station size (L*W*H) | 1500*1350*1600 mm |

Application field | Aerospace, oil field parts, military industry, bearings, automobiles, agricultural vehicles, motorcycles, metal cutting tools, textile machinery, petroleum geological drilling, construction and other high-tech and traditional industries. |

*The above figures are for reference only

We can produce according to your requirements! ! !

Product Description

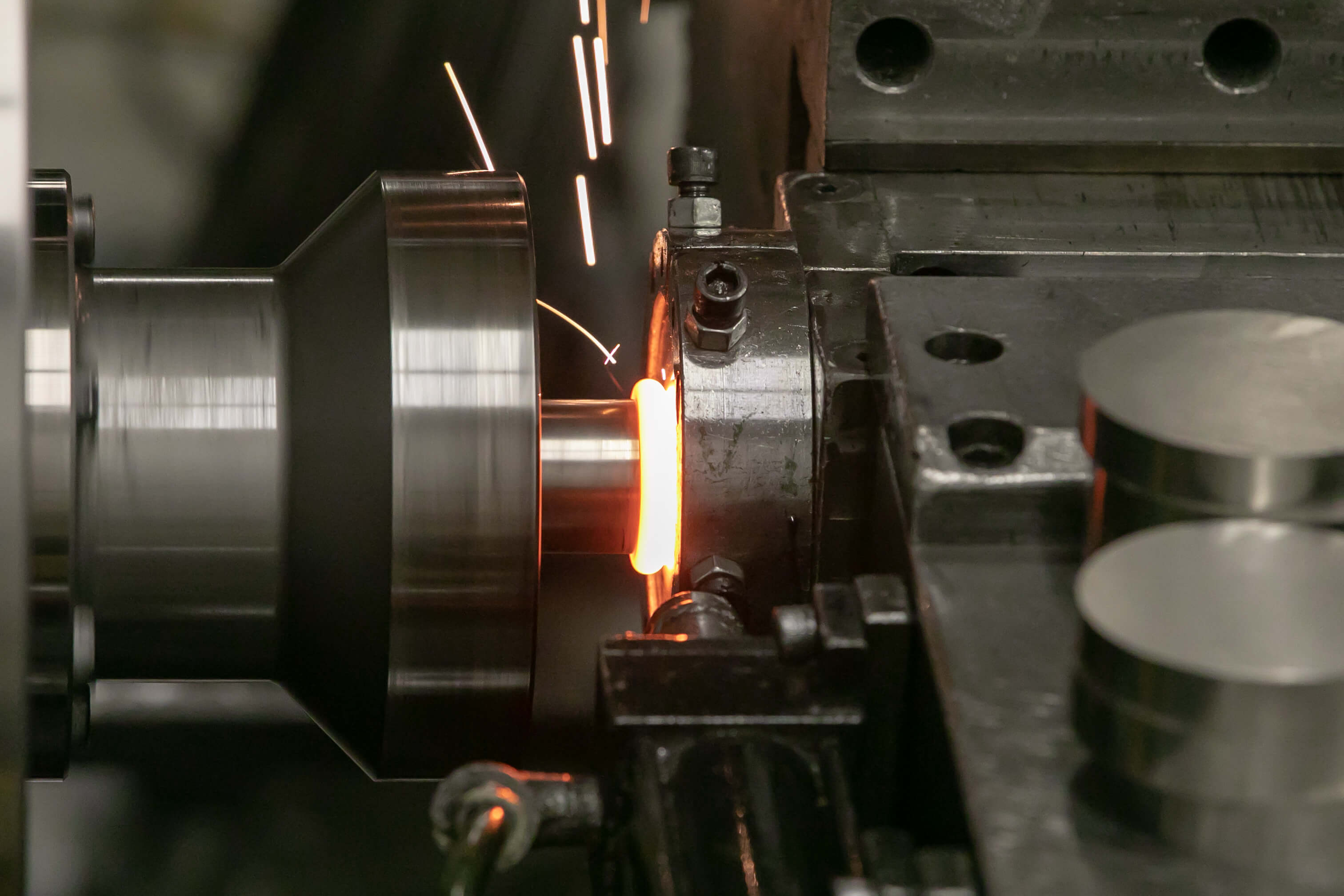

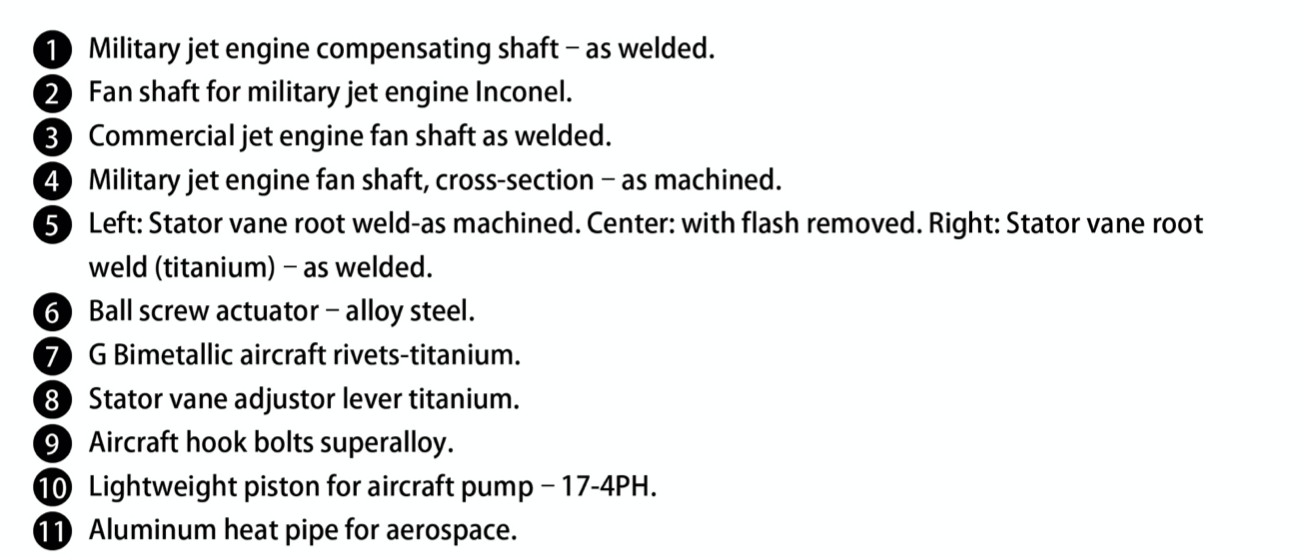

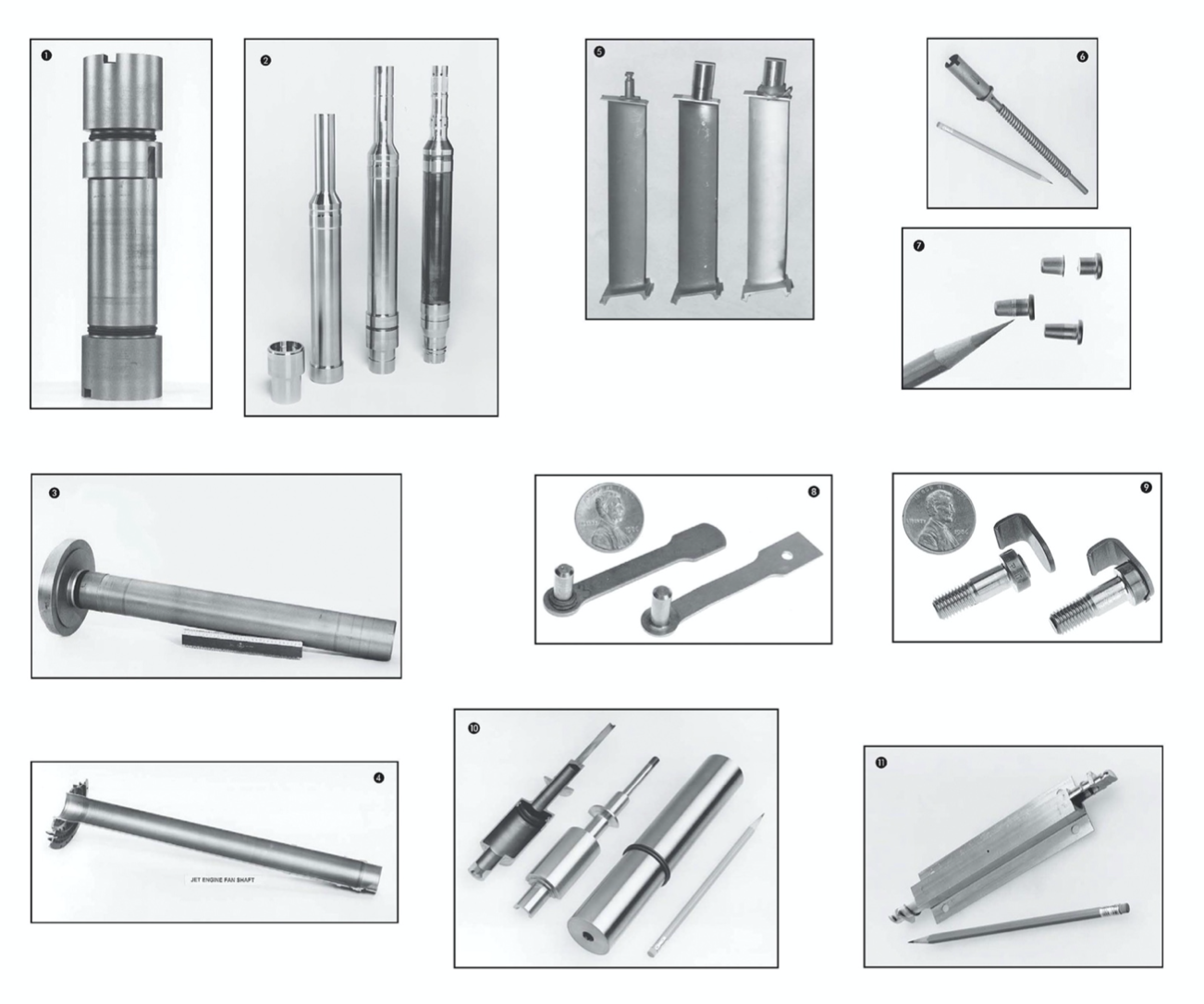

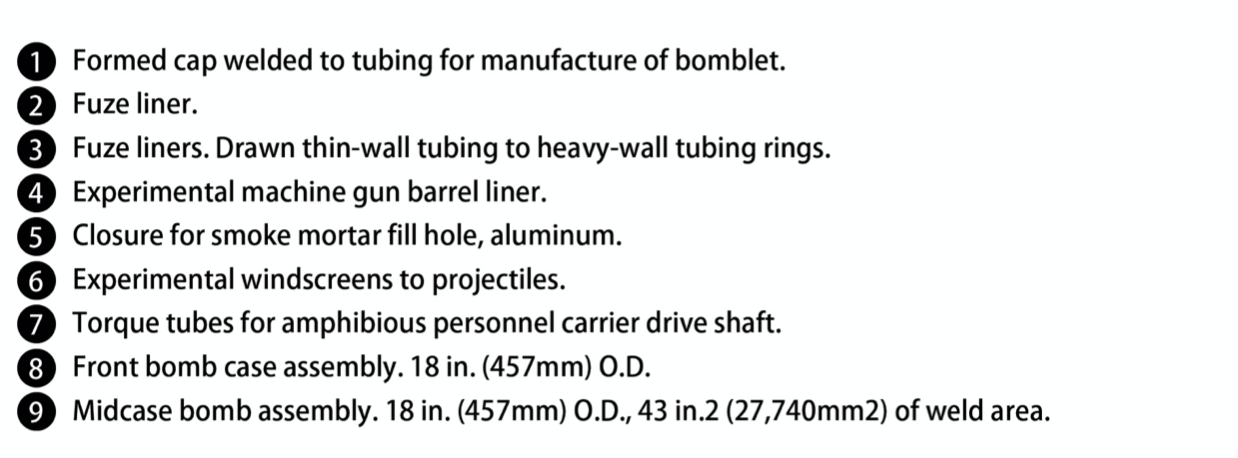

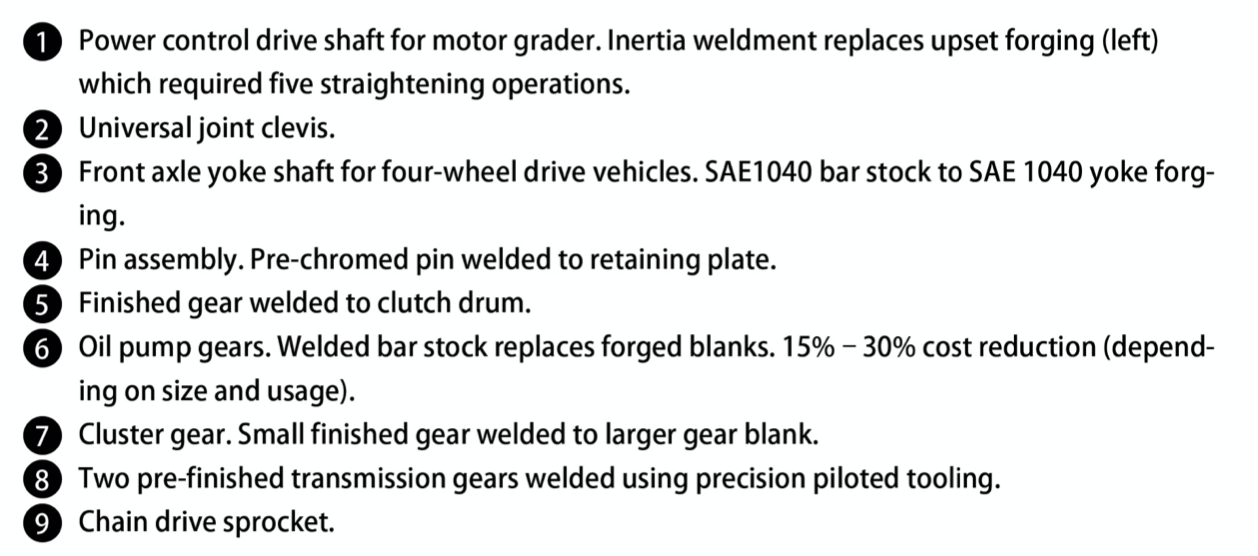

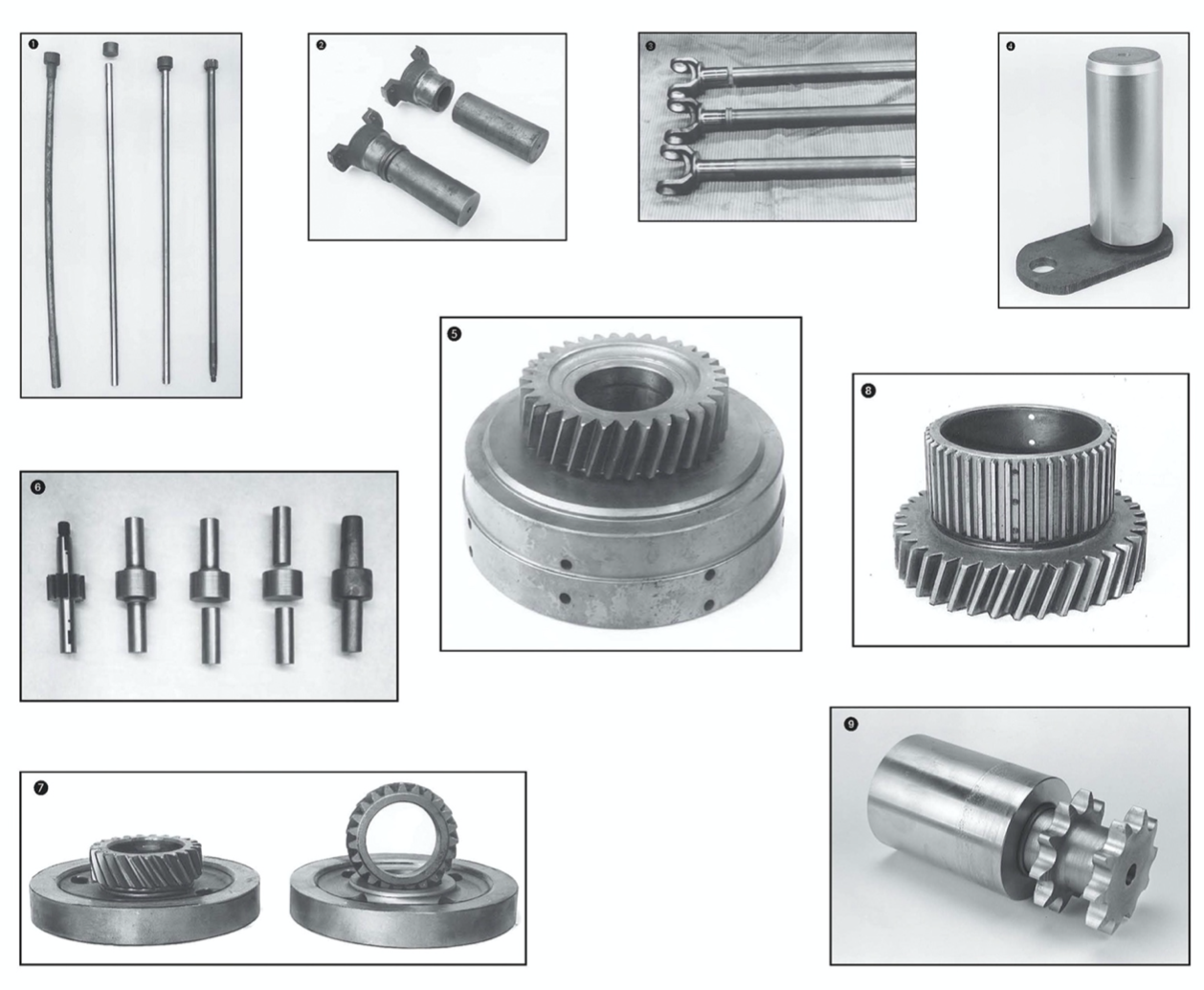

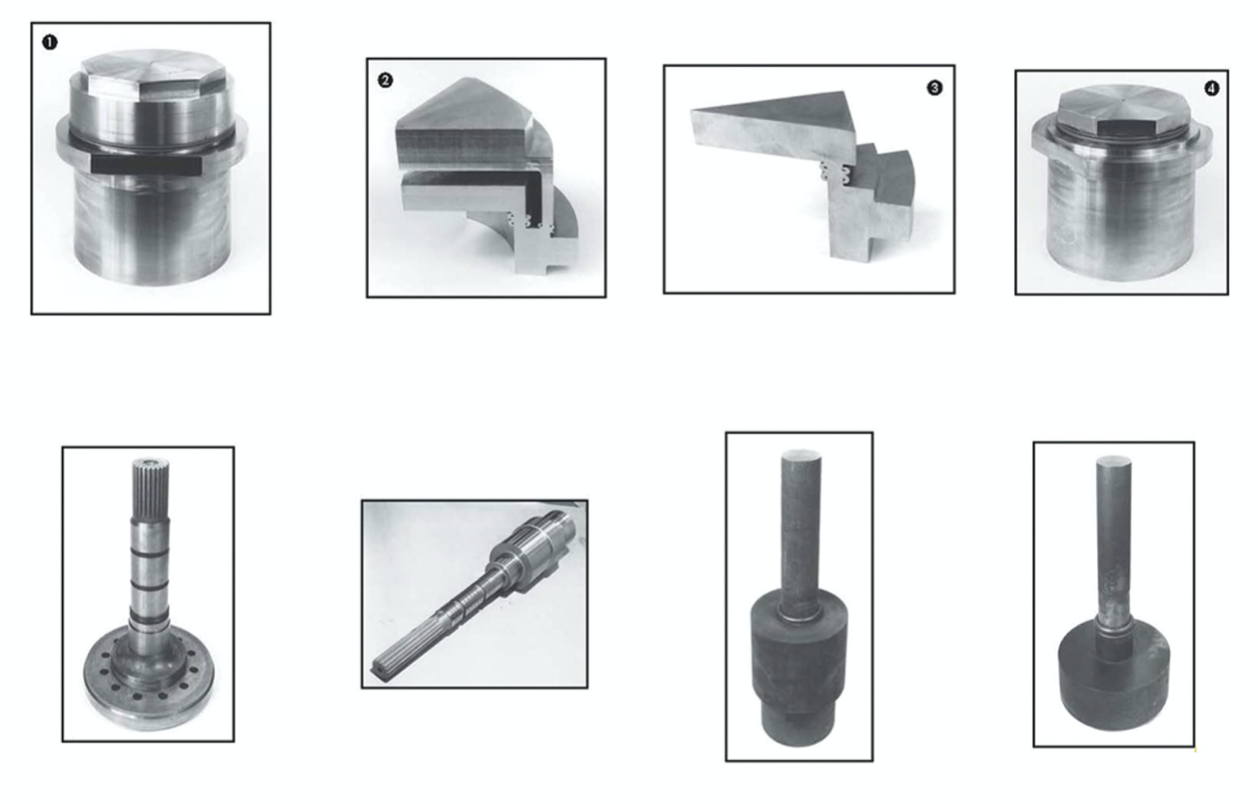

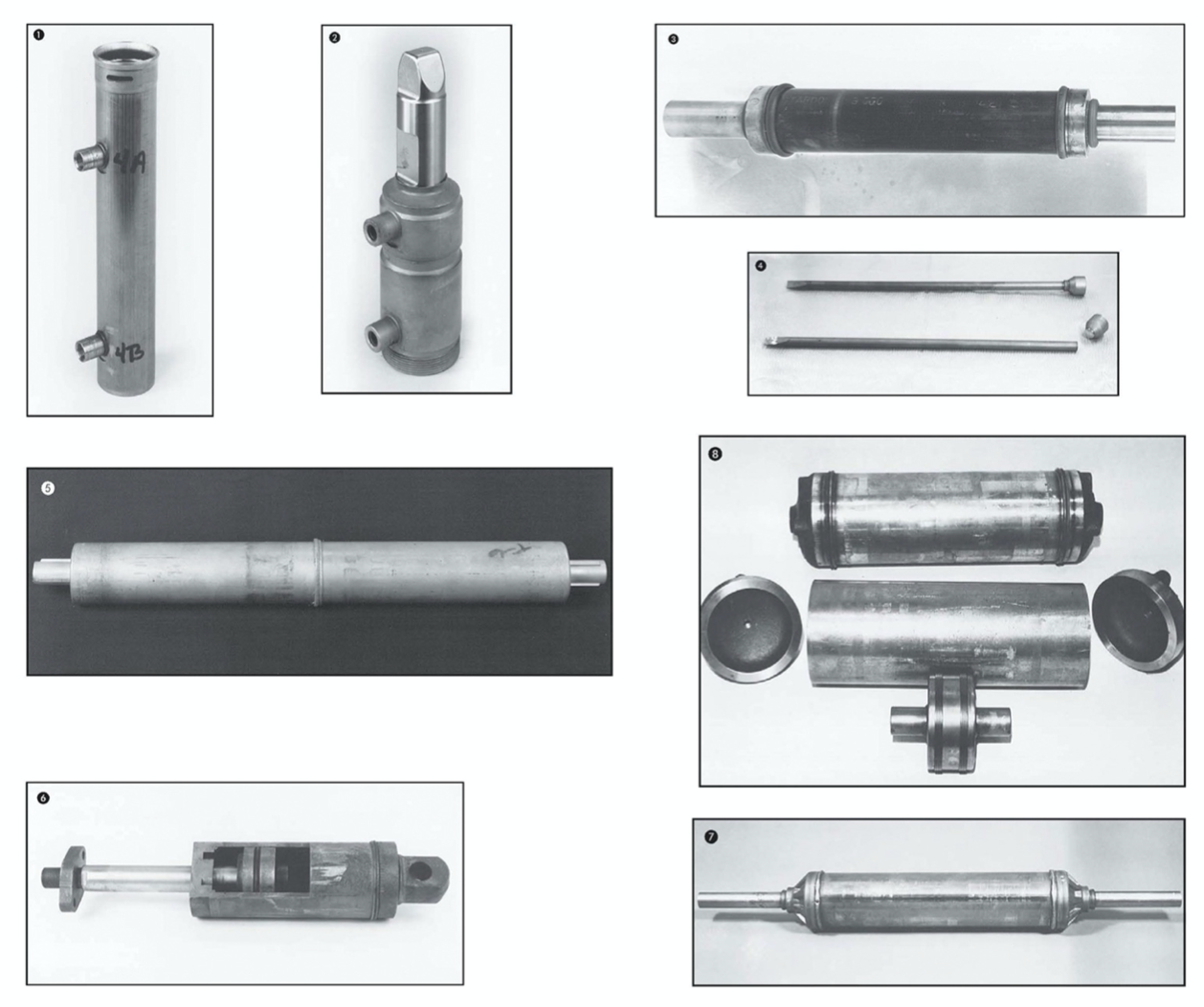

What is friction welding

Friction welding is a solid-state joining process that uses the heat generated between surfaces to create coalescence in materials through a combination of mechanically induced frictional motion and an applied load. The resulting joint is of forged quality. Under normal conditions, the joint surface will not melt. The process does not require filler metal, flux and shielding gas.

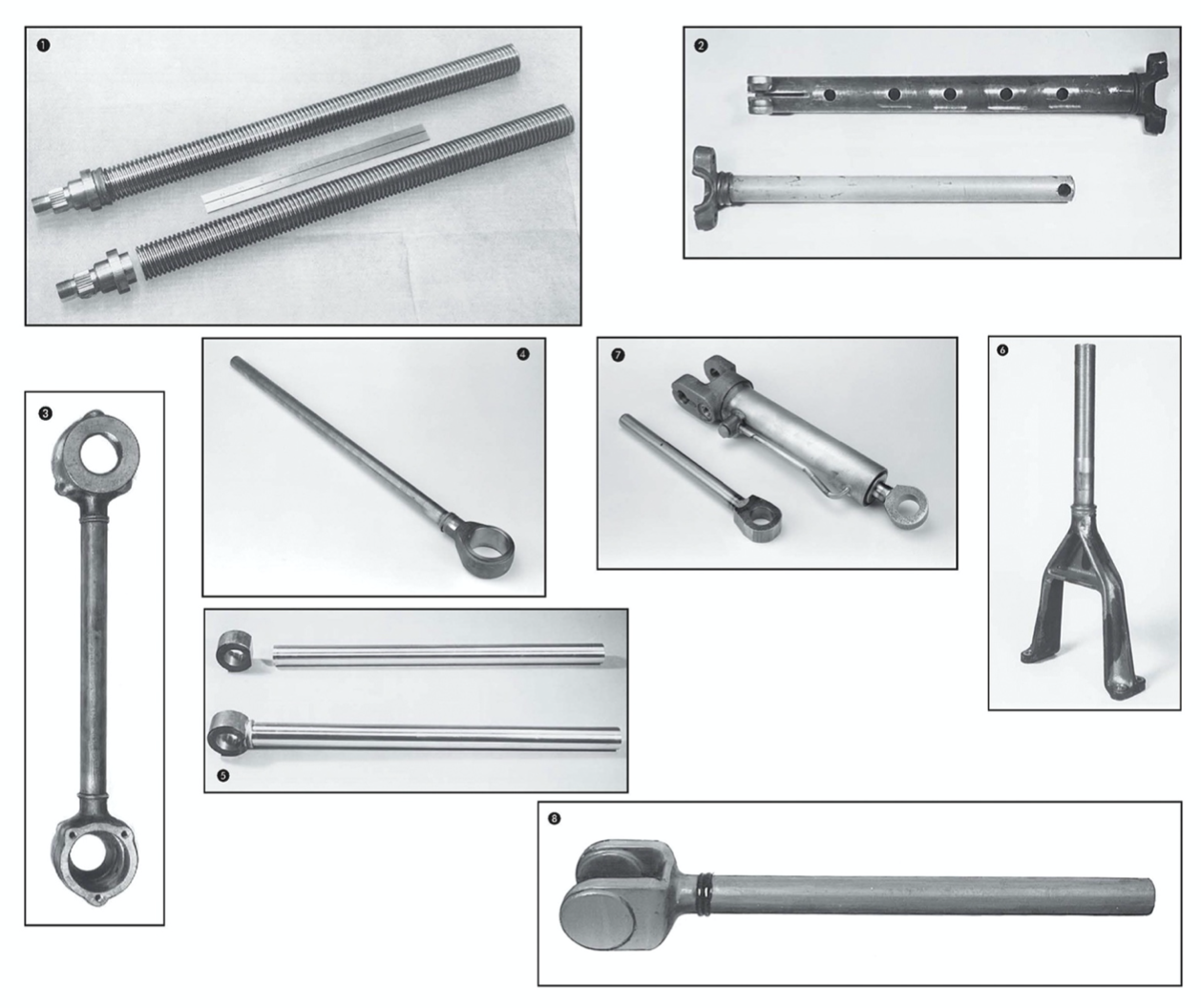

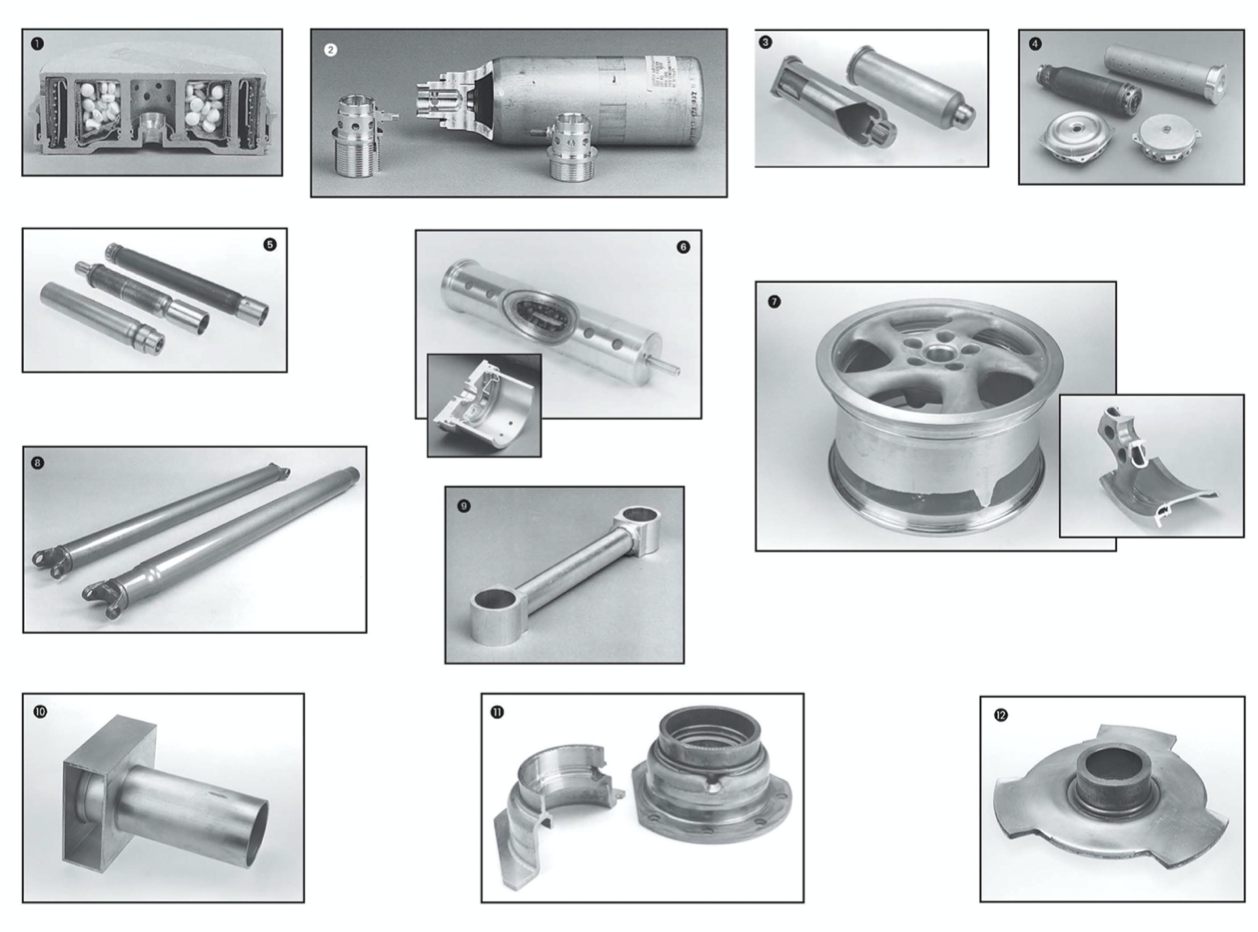

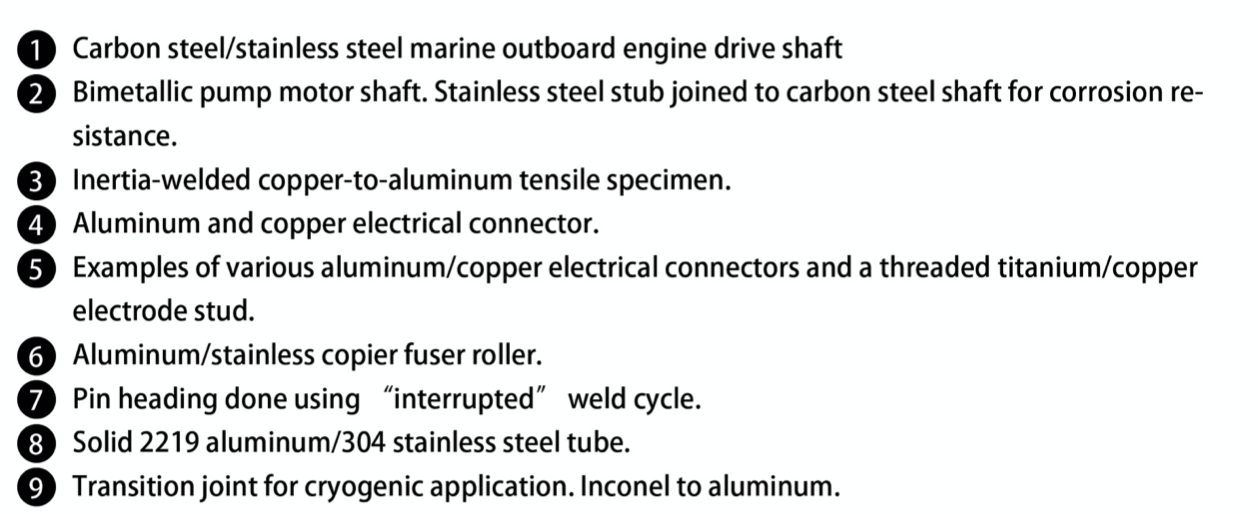

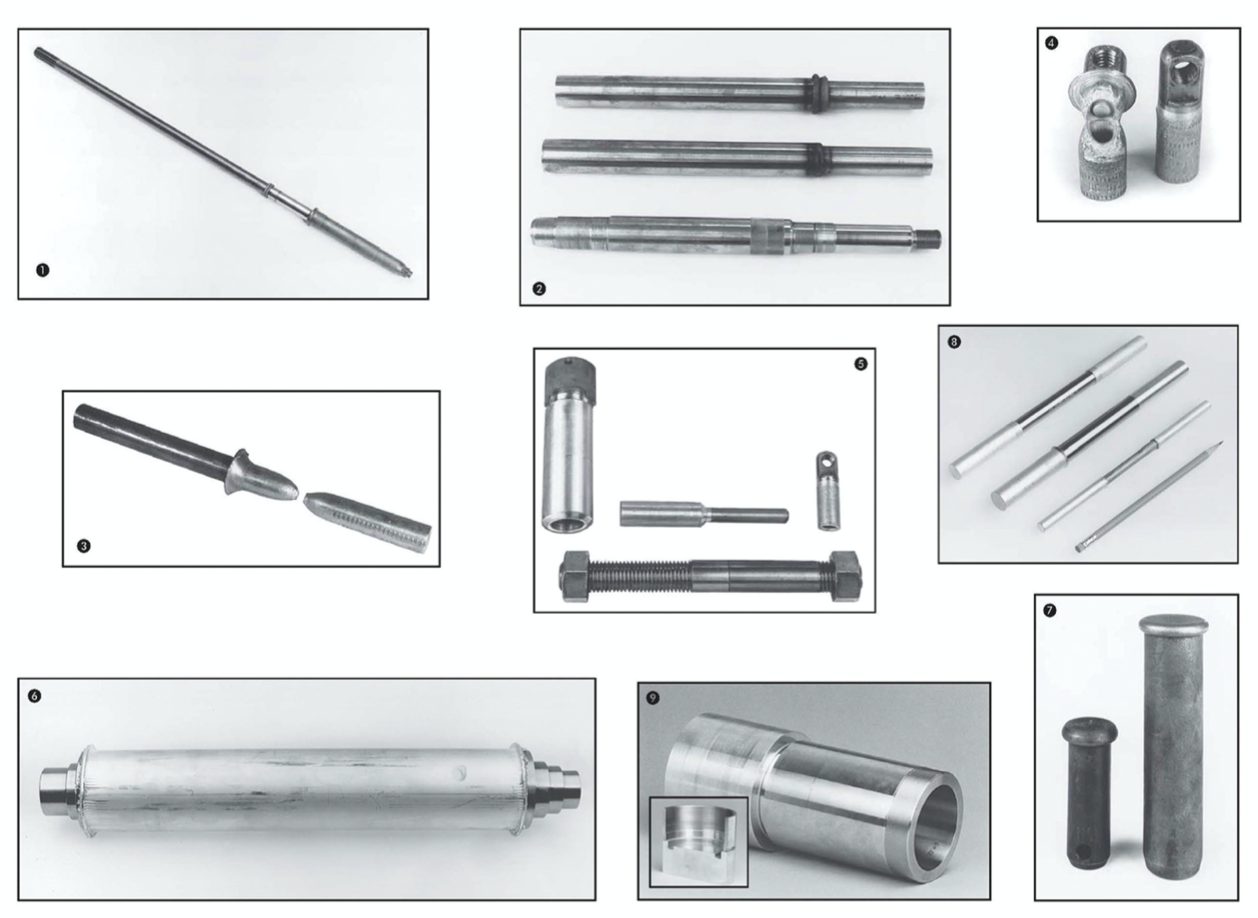

dissimilar materials

Even metal combinations that are generally considered incompatible can be joined by friction welding, such as aluminum to steel, copper to aluminum, titanium to copper, and nickel alloys to steel. Generally, all wrought metal engineering materials can be friction welded, including automotive valve alloys, maraging steels, tool steels, alloy steels and tantalum. In addition, many castings, powder metals and metal matrix composites are weldable.

advantage

Savings - cost, time, material

Since dissimilar materials can be joined, significant cost savings can be achieved, as engineers can design bimetallic components that use expensive materials only when needed. Expensive forgings and castings can be replaced with less expensive forgings welded to bars, tubes, plates, etc.

Since the process is much faster than more traditional welding methods, it can save a lot of time.

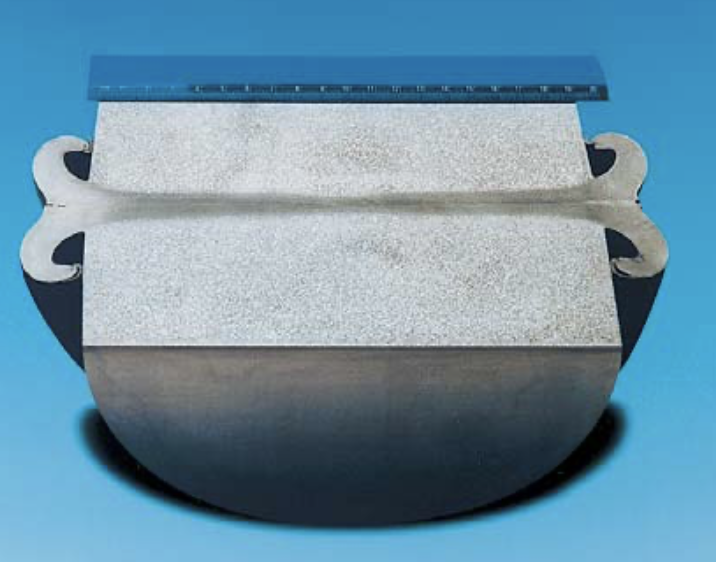

Friction welding produces forged quality joints with 100% butt welds through the contact area. This solid section shows the narrow heat-affected weld zone and the resulting displaced material (flash).

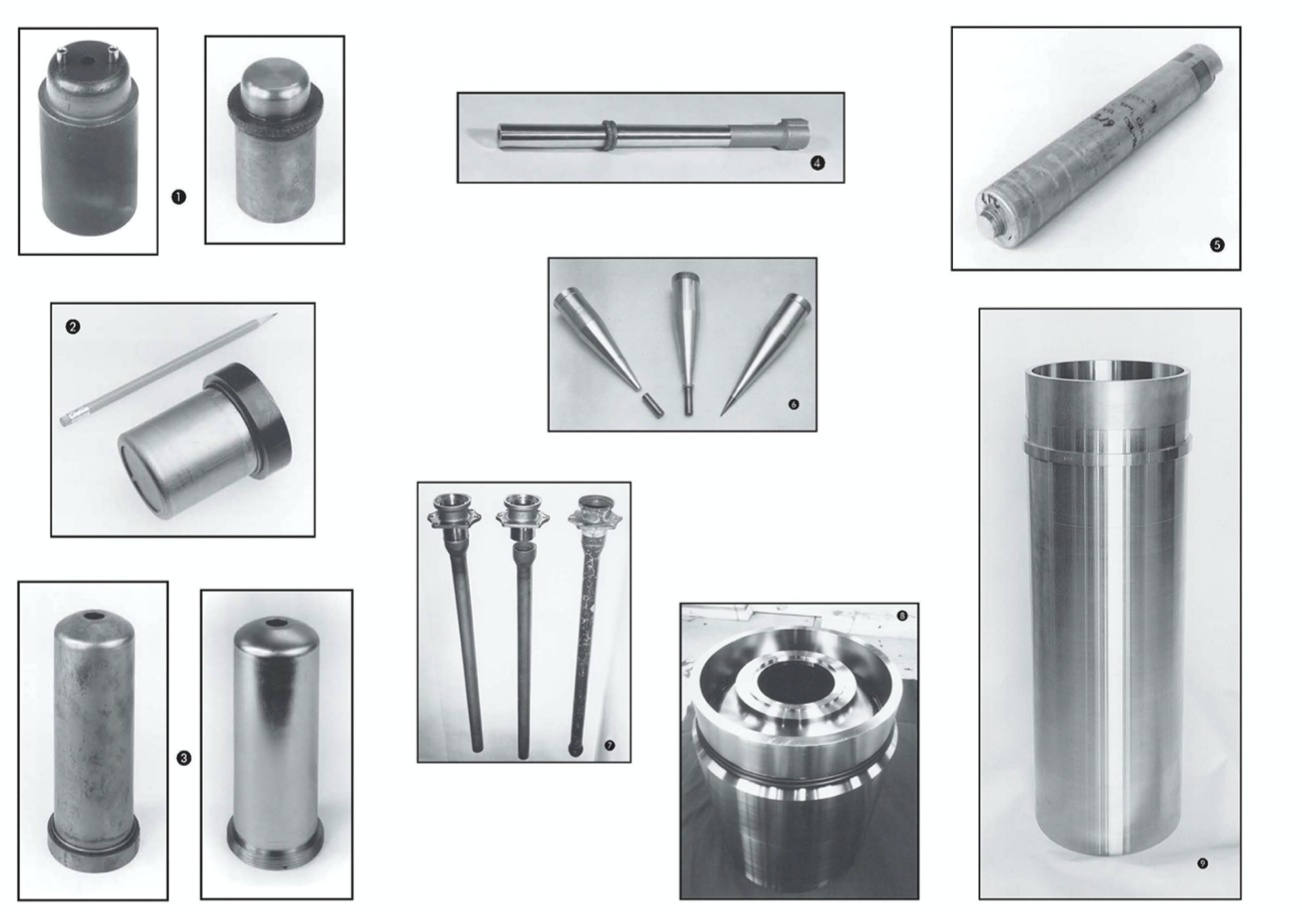

Models and Applications

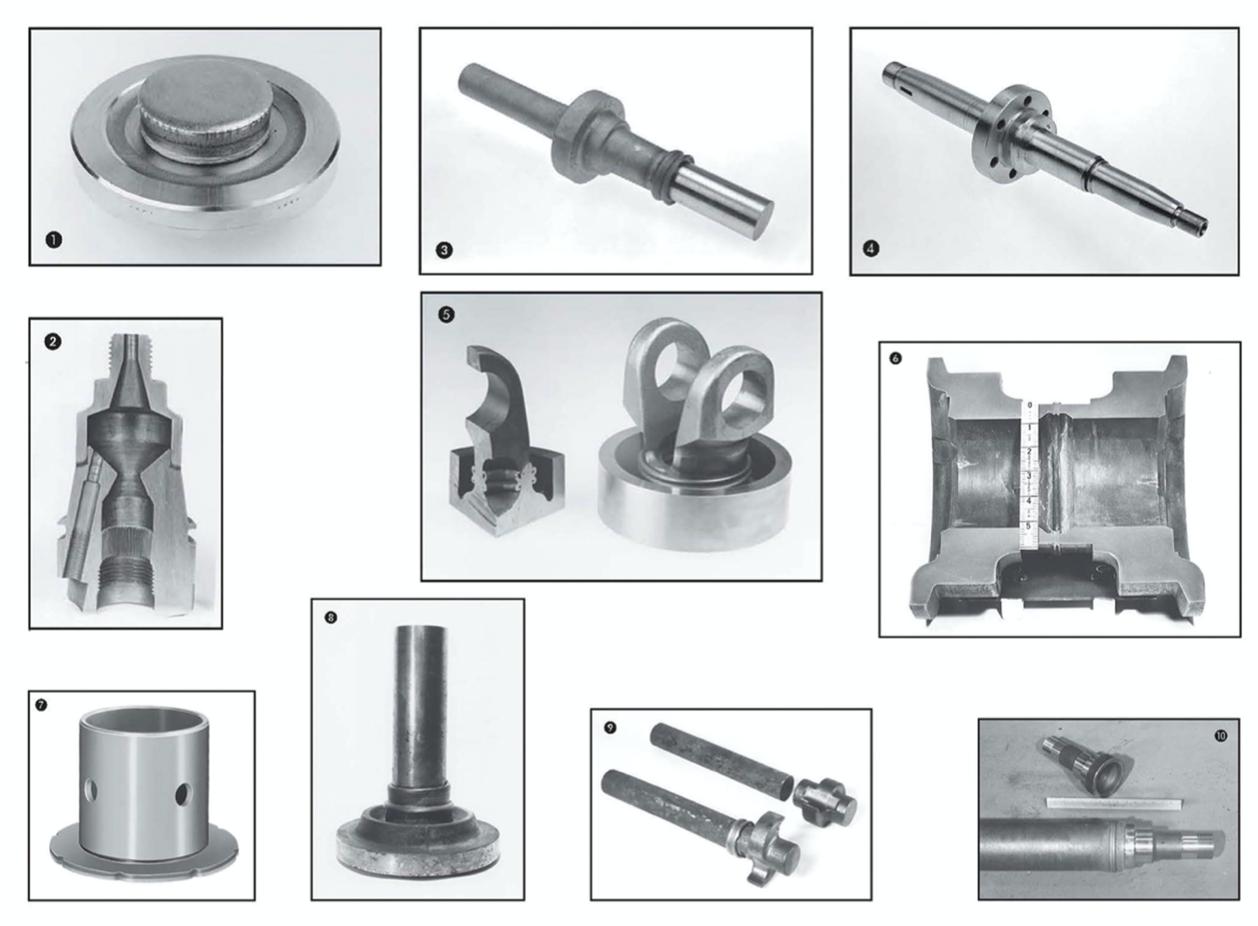

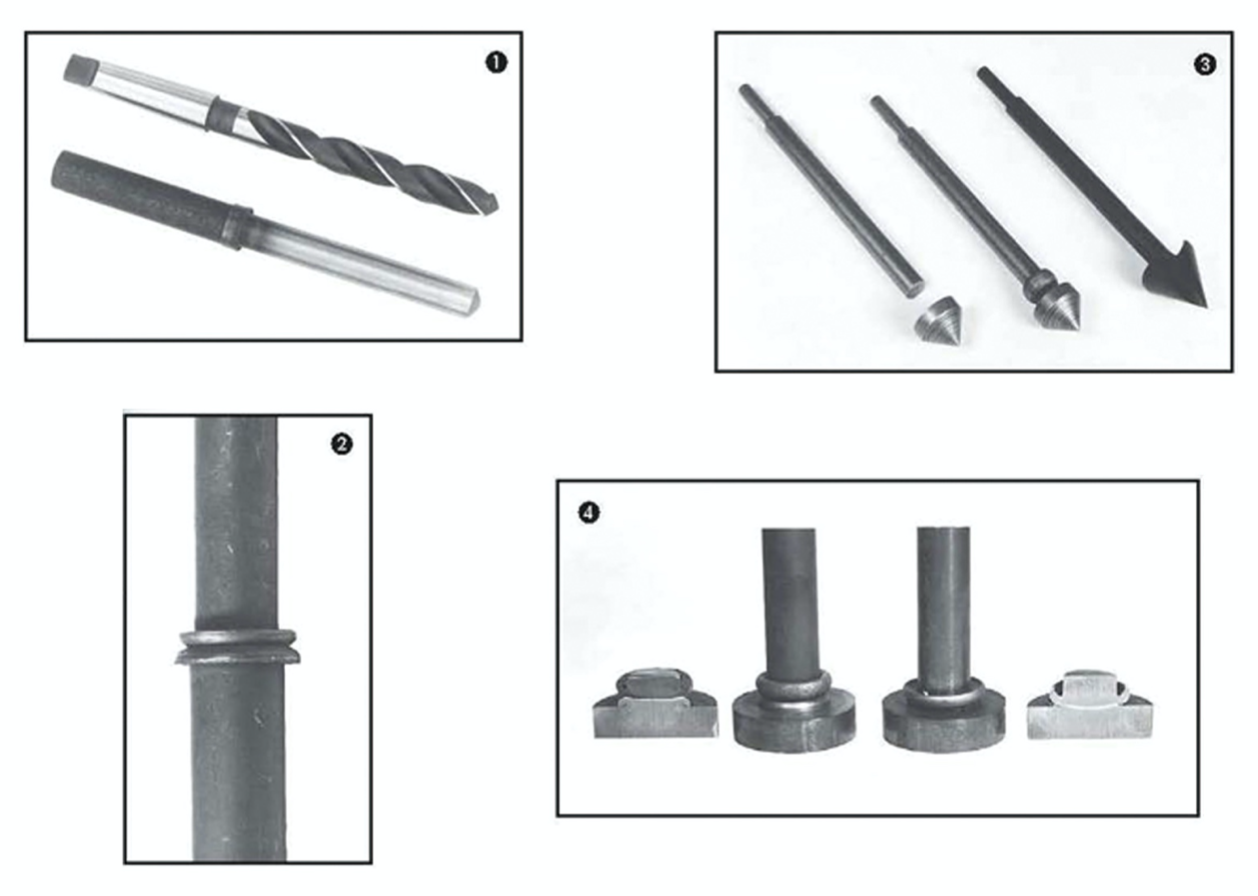

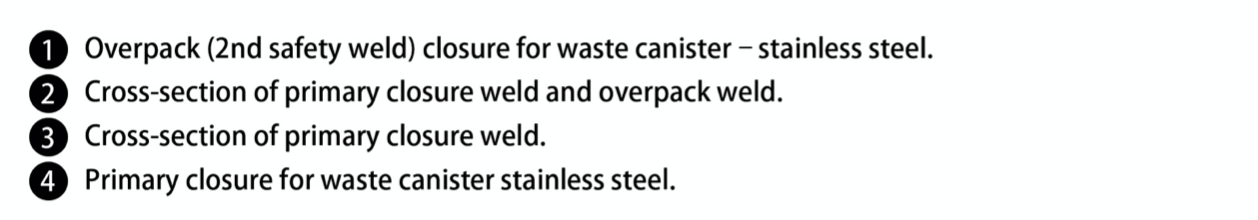

Models and Capabilities | ||||||||||

Model | maximum. The power of distraction (kN) | Welding diameter (mm) | Moving fixture workpiece length (mm) | Rotary Fixture Workpiece Length (mm) | Speed (max) Changing (rev/min) | |||||

C-2.5 | 25 | 6-18 | 50-500 or unlimited | 15-300 | 2500 | |||||

C-4 | 40 | 6-18 | 50-450 or unlimited | 15-300 | 2500 | |||||

C-20 | 200 | 12-35 | 80-750 or unlimited | 50-200 | 2000 | |||||

C-20B | 200 | 14-35 | 80-750 or unlimited | 50-300 | 1800 | |||||

C-25 | 250 | 14-40 | 80-750 or unlimited | 50-300 | 1800 | |||||

C-32 | 320 | 18-50 | 80-850 or unlimited | 50-300 | 1500 | |||||

C-40 | 400 | 20-60 | 80-750 or unlimited | 50-300 | 1500 | |||||

C-50 | 500 | 18-70 | 80-750 or unlimited | 50-300 | 1350 | |||||

C-80 | 800 | 45-80 | 100-1100 or unlimited | 50-300 | 1350 | |||||

SFC-10 | 100 | 12-26 | 80-750 or unlimited | 50-200 | 0-1500 adjustable | |||||

SFC-30 | 300 | 12-50 | 80-750 or unlimited | 50-300 | 0-1800 adjustable | |||||

SFC-40 | 400 | 30-60 | 80-750 or unlimited | 50-300 | 0-1200 adjustable | |||||

We customize friction welding machines according to customer requirements. | ||||||||||

Product packaging

Export Standard Packaging-Wooden Box Packaging Film

VIEW MORE

YOU MAY LIKE