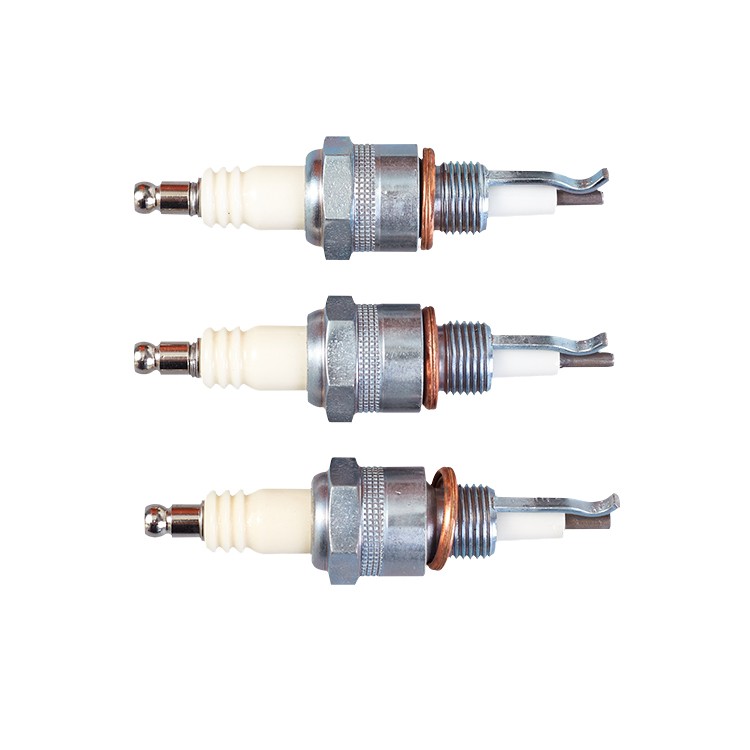

Aluminum ceramic ignition electrode rod for gas burner

- $1.00 / >=100 pieces

- 100 pieces

- Yangzhou Burning Ignition Equipment Co., Ltd.

- Jiangsu, China

- Mr

PRODUCT DETAIL

| port: | Shanghai/Ningbo | brand: | Recording/Labeling |

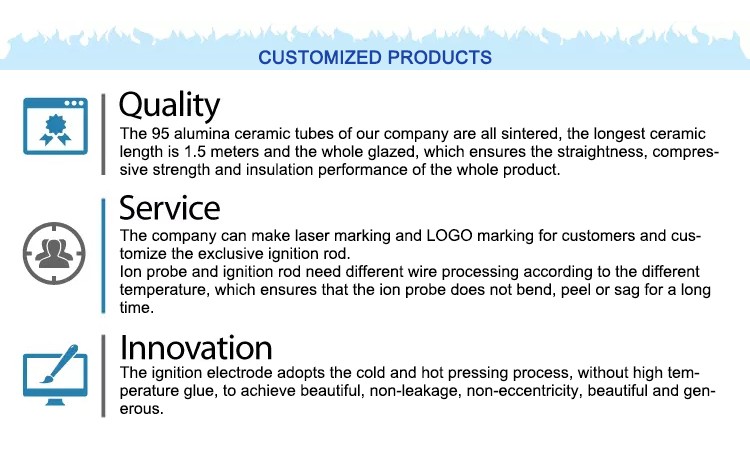

| color: | customer request | Advantage: | Quality hot and cold production process |

| Pay: | T/T, L/C | place of origin; place of origin: | Jiangsu, China |

| Certificate: | International Organization for Standardization | feature: | environmentally friendly |

| Key words: | Alumina Ceramic Ignition Electrode Rod for Gas Burner | trademark: | Laser Marking |

| application: | Gas stove/burner/boiler/industrial equipment | Free samples: | usable |

| Supply capacity: | 1,000,000 pieces per month | payment terms: | L/C, T/T, Western Union, MoneyGram |

| Material: | Alumina-Zirconia, 95% Alumina, Kanthal-A1 | Types of: | Electric ceramic |

| Packaging Details: | Carton (350*190*230cm) or alumina ceramic ignition electrode rod for gas burner according to your requirements |

Product Description

Alumina Ceramic Ignition Electrode Rod for Gas Burner

| Detailed table of alumina (Al2O3) ceramic parameters | ||||||||

| Alumina (Al2O3) | ||||||||

| Main technical characteristics of iron-chromium-aluminum electric heating alloy (GB/T1234-95) | ||||||||

| 1Cr13A14 | 1Cr21A14 | |||||||

Related Products

Click here to customize exclusive products!

customized product

our company

our exhibition

hot sale display

Packaging and Shipping

FAQ

VIEW MORE

YOU MAY LIKE