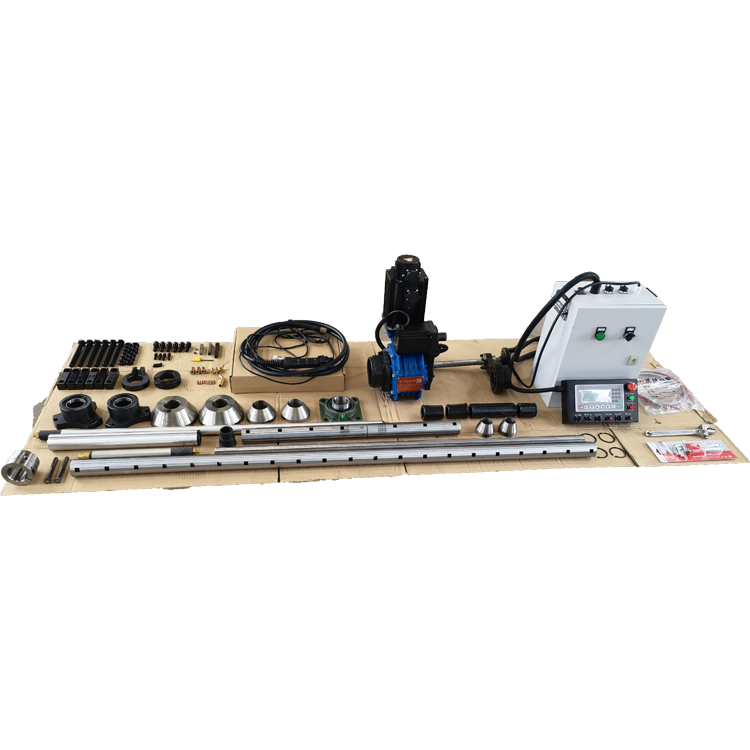

LTWL-50 Electric Portable Line Boring Welding Machine

- $1600.00 /set

- 1 set

- Xinxiang Lantu Machine Tool Co., Ltd.

- Henan, China

- Mr Hao Zhang

PRODUCT DETAIL

| Video outbound inspection: | if | Boring bar (standard): | 50*1600+50*700 mm (support customization) |

| Boring range: | 55-260 mm | Travel (W axis) (mm): | 260 mm |

| type: | vertical | Mechanical test report: | if |

| Supply capacity: | 30 sets per month | Marketing Type: | Hot Products of 2022 |

| Spindle motor power (kW): | 3 | Spindle speed range (rpm): | 200 rpm |

| Number of axes: | 2 | Table travel (Y) (mm): | 0mm |

| brand: | LT | Table travel (Z) (mm): | 0mm |

| Weight (ton): | 0.05 tons | Applicable industries: | Manufacturing plants, machine repair shops, farms, retail, construction, energy and mining |

| Main selling points: | multifunctional | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Accessories: | Elective | After-sales service: | Online Support/Video Support |

| Voltage: | 110V/220V/380V | Health status: | new |

| Boring bar speed: | 0-200rpm (stepless speed regulation) | Power type: | 3 kW servo motor |

| Feed stroke (standard): | 260 mm (support customization) | Showroom location: | not any |

| Production capacity: | 30 | Operation method: | automatic |

| Package preview: | Table travel (X) (mm): | 260mm | |

| Warranty: | 1 year | Origin: | Henan, China |

| Whether CNC: | CNC system | Packaging Details: | Fumigation and disinfection plywood packing box |

| End device feed: | 0.1 mm | port: | Qingdao Port |

| Feed rate: | 0-3 mm (stepless speed regulation) | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| Core component warranty: | 1 year |

Specification

Name | LTWL-50 Worm Gear Boring Welding Machine |

Model | LTWL-50 |

Maximum aperture mm | 260 |

Minimum aperture mm | 55 |

Feed stroke mm (standard) | 260 (support customization) |

Boring bar mm (standard) | 50×1600 mm (customized) |

Boring bar speed Rpm | 0-200r/min (stepless speed regulation) |

Motor power Kw | 3 kW |

power type | servo motor |

Feed mm | 0-3mm (stepless speed regulation) |

End device feed | 0.1/0.15 |

One side cutting depth mm | ≥3 mm |

roughness | Ra3.2 |

Roundness mm | ≤0.02mm |

operation method | automatic / manual |

Host weight Kg | 60 |

pack | Fumigation and disinfection plywood packing box |

Our company's patented portable drilling machine is designed for on-site construction. It is good at both drilling and welding. It has the characteristics of small size, light weight, and good boring and welding quality. It can be conveniently used for on-site drilling and welding of large steel structures, especially suitable for processing in narrow spaces. Widely used in the repair of large equipment, construction machinery pin holes, bearing holes and other round holes.

1. Choice of surfacing or boring mode 2. Choice of clockwise or counterclockwise rotation direction 3. Infinitely variable speed control 0–200 rpm 4. Choice of forward or reverse feed direction 5. Stepless feed speed 0–200 rpm 33 mm/min 6. Automatic operation boring mode: set the cutting length in millimeters, then the machine returns to the starting position at high speed 7. Automatic mode surfacing: set speed, surfacing step, surfacing length, rotation direction- The machine performs surfacing and closes when it arrives at the end of the work. 8. Automatic mode fan-shaped surfacing: set the surfacing angle, speed, retreat amount and surfacing length-the machine performs surfacing on the set sector and stops

Product Description

VIEW MORE

YOU MAY LIKE