Tire Clamshell Machine for Tire Retreading Process

- $50000.00 /set

- 1 set

- Rizhao Melion Industry Co., Ltd.

- Shandong, China

- Mr Joe Yan

| heating method: | electric | Video external inspection: | if |

| Function: | Review of used truck tires | place of origin; place of origin: | China |

| brand: | melon | payment terms: | Western Union, wire transfer |

| port: | Qingdao | Mechanical test report: | if |

| train: | Yes | Packaging Details: | Suitable for long-term ship transportation |

| technology: | Melion Precure Refurbished (Cold) | Main selling point: | multifunctional |

| describe: | tire retreading machine | Showroom location: | not any |

| Standard chuck rims: | 15"-20" | After-sales service provided: | Engineers can go overseas to service machinery, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, online support, video technical support |

| Power (kW): | 98 | Applicable industries: | tire machinery |

| Voltage: | 380v | Health status: | new |

| Supply capacity: | 100 sets of tire retreading machines per month | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Core Components Warranty: | 2 years | Warranty: | 2 years |

| Gas source: | 0.6-0.8 bar | Local service location: | not any |

| Marketing Type: | Hot Products of 2021 | Optional heating: | Steam, oil heating |

| Core components: | PLC, pressure vessel | Weight (kg): | 5800kg |

| control: | car |

Tire flipping machine for retreading old truck passenger car tires

Melion Refurbishment Technology:

Precuring or "cold" tire retreading involves vulcanization without molds at temperatures between 95 °C and 117 °C. The tire is assembled using a layer of pre-cured tread liner rubber (= new tread) and a layer of non-vulcanized adhesive (buffer). The bond between the carcass, the binder and the precured tread is formed in an autoclave (curing chamber). Since the introduction of radial tires in the mid-1960s, the truck tire industry has fully established pre-curing.

Complete set of tire flipping machine/tire retreading machine

Preliminary inspection machine, polishing machine, dust collector, multi-function maintenance table, extruder, cement mixing tank, forming machine, wrapping machine, rim mounting machine, monorail, curing chamber, pressure testing machine, etc.

Melion Precure Tire Retreading Equipment Process

1. Collection of shells

Collect worn tires to select a suitable carcass for retreading.

2. Preliminary inspection

Every tire received by the retreading plant undergoes a rigorous visual inspection. Assist the inspector with a non-destructive precision MELION inspection machine.

3. Polishing after inspection

The old tread of the tire is mechanically removed on the high-speed bumper. MELION's bumpers are so accurate that they remove just the right amount of old rubber while turning the tire to the exact specified diameter and radius.

4. Partial Repair and Scraping

With advances in state-of-the-art repair materials and repair methods, many of these tires can be repaired routinely and, in most cases, retreaded when the original tread wears out. A repair station is where sanding and refinishing is done with effective materials and tools.

5. Cementing and filling

Cleaning and filling the wound is important even for minor injuries. If you don't do this, severe rust, separation, and loose cables can put the tire out of service. Damage should be checked and then removed with a carbide tool. Once the wound is immobilized, a vulcanized rubber rod should be used to "fill" the wound. This will create a permanent repair that maximizes tire life.

With MELION designed and built spray booths, your cementing operations can be carried out in a clean, efficient and environmentally friendly manner.

6. Construction - Tread Rubber

In a pre-cured system, the tread compound is already vulcanized and a new tread pattern design is used. Polished tires need to be wrapped with a thin layer of cushioning rubber in the crown area. The precured tread rubber is then used with the molding machine. This is called the build process.

7.a) Envelope and Rim Mounting

The assembled tire is then mounted on the skin and rim in preparation for vulcanization.

b) or double envelope system

For the envelope, the tire first installs an outer envelope on the envelope mount, and then installs the inner envelope into the tire. The encapsulated tire is then evacuated to prepare it prior to curing. The housing of the modern factory is lifted by a monorail system. With professional planning by MELION engineers, you can rest assured of a workstation designed to maximize output and streamline workflow.

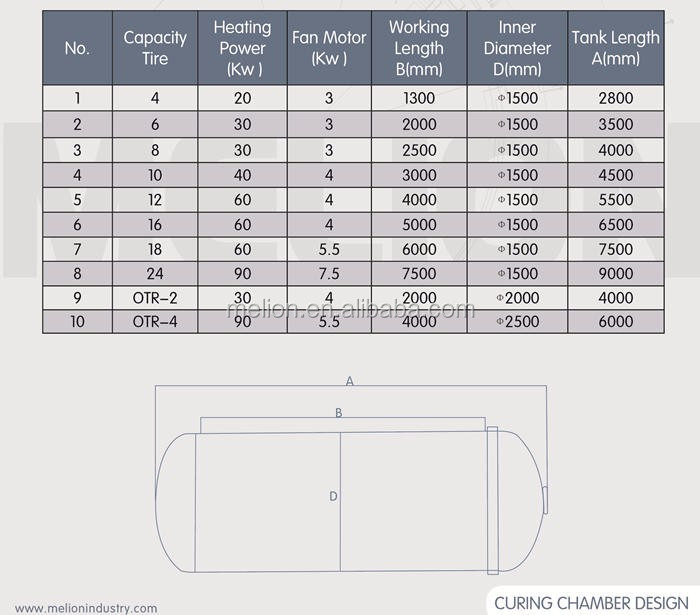

8. Chamber curing

The tire is then placed in a curing chamber and the precured tread adheres to the tire through the curing process.

Our extensive engineering capabilities and experience allow MELION to build chambers according to customer preferences for size, steam heating, electric heating or dual heating systems, semi-automatic and automatic chambers.

The monorail and hook system increases productivity by reducing the chance of housing contamination and allows for faster tire loading and unloading. This increases safety and productivity in your workplace.

9. Final inspection and painting

Retreaded tires undergo a final inspection. This inspection ensures that only tires that meet industry quality standards leave the retreading facility. All retreaded tires are encouraged to be returned with a thin layer of black tire paint on their sidewalls.

We manufacture complete tire retreading machines from 4 to 24 tires to meet different buyer requirements. Our engineers can come to the buyer's factory to help with installation and provide technical courses for workers. Using our premium pre-cured tread rubber materials, rubber strips and cushioning compounds guarantees you a quality retreaded tire product.