mosaic glass cutting machine manual glass cutting machine

- $3300.00 /piece

- 1 piece

- Anhui Ruilong Glass Machinery Co., Ltd.

- Anhui, China

- Mr Gale Gao

| Showroom location: | not any | strength: | 2kW |

| accuracy: | ±0.10mm/m | Production capacity: | 1-2/min |

| Main selling point: | easy to operate | weight: | 500 kg |

| Warranty: | 1 year | place of origin; place of origin: | Anhui, China |

| Packaging Details: | Frame manual glass cutter for masic glass cutter | Maximum cutting size: | custom made |

| Type of machine: | glass cutting machine | Core components: | Pump |

| Dimensions (L*W*H): | 1300*1600*1300mm | payment terms: | Letter of Credit, Western Union, T/T, MoneyGram, PayPal |

| minute. Cutting Machine: | 20mm*20mm | Health status: | new |

| port: | Shanghai | Supply capacity: | Annual production of 1000 pieces of manual glass cutting table |

| Applicable industries: | Building materials store, manufacturing plant, machinery repair shop, other | Certification: | ce |

| Core Components Warranty: | 1 year | After-sales service provided: | Provide overseas service center |

| Marketing Type: | normal product | brand: | Ruilong |

| glass thickness: | 2-25mm | Diagonal accuracy: | ≤±0.25mm/m |

| Mechanical test report: | if | Video external inspection: | if |

| Name: | Mosaic Glass Manual Glass Cutting Machine |

| Name | manual glass cutter for masic glass cutter |

| Model | SY-1215 |

| type | manual |

| maximum. glass size | 1200*1500×1300mm |

,

introduce

SY series manual high-precision multi-knife cutting is widely used in online/offline cutting of flat glass, ultra-thin glass, liquid crystal glass, ceramic glass, and amorphous glass. Easy operation, stable work, fast cutting speed, high precision, long tool life and maintenance-free.

feature

Accuracy: ≤±10mm/m

Diagonal accuracy: ≤±0.2mm/m

maximum. Size: 1200*1500×1330mm (customized with special specifications)

minute. Size: 20*20mm (smaller size can be customized.)

Thickness: 2-25mm

Speed: 1-2 large/min

Cutter wheel life: 3--50,000 meters (ordinary straight cutting)

Operator: 1-2

introduce

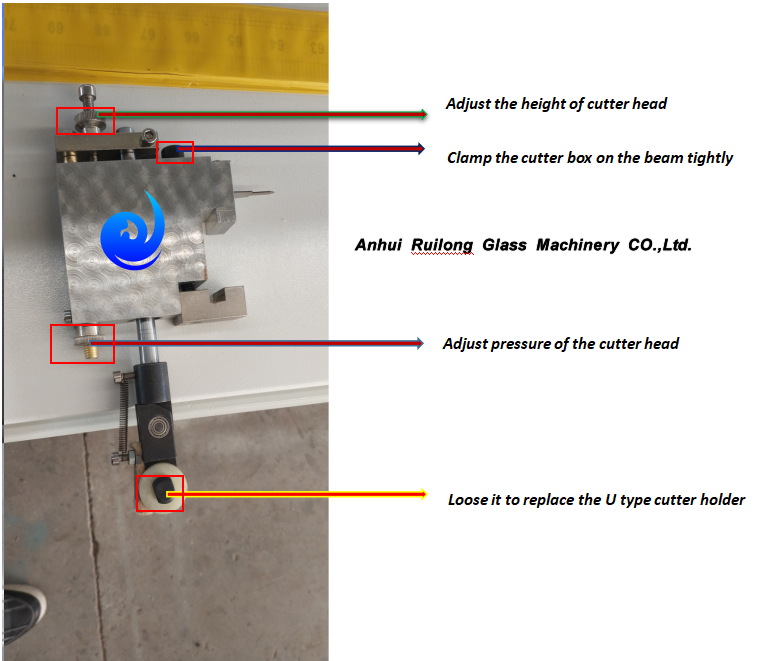

(1) Adjust the tool box

Put the small glass into the bottom of the cutting wheel, loosen the screw on the knife box, turn the screw so that the bottom of the knife box and the glass surface form an angle of 60°-75°, then tighten the screw and turn. Another turn the screw of the knife box knife to adjust the knife pressure.

(2) Adjustment of cutting size

First adjust the first knife box, then loosen the bolt, so that the pointer is aligned with the locked steel ruler scale; and adjust the second knife box in the same way, try cutting, after passing, adjust the third one as before, so that analogy.

Shipping and Installation Considerations

During the handling process, handle it with care, and do not collide. It is forbidden to use guide rails and beams as supporting parts. When installing, check the table with a spirit level, and adjust the four feet to make the table level.

Maintenance and Repair

Fill the oil tank on the beam with clean oil or chemical before cutting; adjust the corresponding angle on the oil tank to make the linoleum full of kerosene and chemical.

The protection and maintenance of the moving shaft under the longitudinal beam before and after using some oil.

Push the vertical beams back into place, then push the horizontal beams back into place to avoid collisions while working.

After cutting the glass, clean the table and wipe down the equipment.

Do not stack heavy objects or drop watering and oily liquids on the tabletop to prevent deformation.

Configuration:

1 frame: national standard square tube

2 Table: imported Kangbei waterproof board plus felt, not deformed.

3 axles: 50 bearing steel

4 fans: Shanghai