Automatic Transformer Foil winding machine for Winding Low Voltage Copper Aluminium Coils

- $48900.00 / 1 - 1 sets

$47600.00 / 2 - 4 sets

$46700.00 / >=5 sets - 1 set

- Jiangxi Hongjun Environmental Protection Technology Co., Ltd.

- Jiangxi, China

- Mr John Xiong

PRODUCT DETAIL

| Length of Axis (mm): | 450; | Delivery time: | in 50 working days; |

| Packaging Detail: | With Plastic Film Package Or As per Client's requirements.; | Thickness Range(mm): | 0.5~2 mm; |

| CNC or Not: | CNC; | Max.Winding Width(mm): | 400; |

| Port: | FOB Shanghai; | Coil Type: | Round,Oval,Rectangle; |

| Applicable Industries: | Retail,Other,Manufacturing Plant; | Coil width: | 400 mm; |

| Machinery Test Report: | Provided; | Cutting Method: | Atomatic; |

| Key Selling Points: | Automatic; | Material: | Other; |

| Model: | BRJ-400-2; | CNC System: | PLC; |

| Winding speed: | 24 RPM; | Decoiler Quantity: | 2; |

| Dimension(L*W*H): | Custom; | Product name: | low pressure foil winding machine; |

| Package Preview: | ; | Foil thickness: | 0.5~2 mm; |

| Place of Origin: | Jiangxi, China; | Warranty: | 1 Year; |

| Core Components: | PLC,Motor; | Counting Precision: | 0.1; |

| Coil material: | Cu/Al; | Showroom Location: | None; |

| Supply Ability: | 100 Sets per Year; | Marketing Type: | New Product 2020; |

| Warranty of core components: | 1 Year; | Winding power: | 11KW; |

| Brand Name: | HJ; | Welding Method: | TIG; |

| Payment Terms: | Western Union,L/C,T/T,MoneyGram; | MOQ: | 1 set; |

| Video outgoing-inspection: | Provided; | Weight (KG): | 3200; |

| Condition: | New; | Decoiler Loading: | 1000 KG; |

| Winding Speed(rpm): | 24; | Insulation Quantity: | 2; |

Production Description

Typical standard specifications are shown below, these can be easily modified as requested. | ||||||||||

Model | BRJ-1600-2 | BRJ-1200-2 | BRJ-1000-2 | BRJ-800-2 | BRJ-400-2 | |||||

Coil width(mm) | 1600 | 1200 | 1000 | 800 | 400 | |||||

Coil form | Round/Rectangular | Round/Rectangular | Round/Rectangular | Round/Rectangular | Round/Rectangular | |||||

coil material | Cu/Al | Cu/Al | Cu/Al | Cu/Al | Cu/Al | |||||

foil thickness | Cu:0.5~1.8 Al:0.5~2.0 | Cu:0.5~1.8 Al:0.5~2.0 | Cu:0.5~1.8 Al:0.5~2.0 | Cu:0.5~1.8 Al:0.5~2.0 | Cu:0.5~1.8 Al:0.5~2.0 | |||||

winding power | 30 KW | 18.5KW | 18.5 KW | 15 KW | 11 KW | |||||

winding speed | 0~24RPM | 0~24RPM | 0~24RPM | 0~24RPM | 0~24RPM | |||||

working pressure | 0~0.6Mpa | 0~0.6Mpa | 0~0.6Mpa | 0~0.6Mpa | 0~0.6Mpa | |||||

working tension. | ≥24000N·m | ≥18000N·m | ≥16000N·m | ≥15000N·m | ≥10000N·m | |||||

loading weight | 3500kg | 3000kg | 2500kg | 2000kg | 1500kg | |||||

Rectify mode | Automatic | Automatic | Automatic | Automatic | Automatic | |||||

welding way | TIG | TIG | TIG | TIG | TIG | |||||

Equipment main part:

1. Uncoiling and rectifying device: (1 set)

2. Charging and wool pressing device;(1 set)3. Cleaning device; (1set)

4. Deviation correction sensor device;(1 set)

5. Sheering device; (1 set)

6. insulation layer and winding device: (1set)

7. End insulation unwinding device; (3 sets left and 3 sets right)

8. Welding device; (1 set )

9. Winding device;(1set)

10. Winding and pressing device;(1set)

11. Layer insulation unwinding device; (2 sets)

General description about the machine

1.Introduction

BRJ-400-2 Automatic Low Voltage Dry Type Transformer Making Equipment Foil Winding Machine is used to wind coils made of copper or aluminum foil. This kind of Automatic Transformer Foil Traverse Winding Machine can handle one or two layers of conductor foil and one or two layers of insulation material (such as paper or similar). Bus bars are welded with TIG welding process. The automatic foil edge alignment will make sure that the coil edges are straight and smooth. Programming of this machine is done by means of a touch screen user interface.

2. features:

1 )Tension system, compare with the traditional passive tension can guarantee the stability of the whole process of winding tension.

1 )Tension system, compare with the traditional passive tension can guarantee the stability of the whole process of winding tension.

2) adjusting system adopts photoelectric sensor, through the motor dynamic action, the system of high precision, fast response,can ensure the winding coil end face and tidy.

3 )Foil belt tension, insulating layer and the parameters of the coil and winding tension state, such as digital setting and display, intuitive and accurate.

4) Open book brake motor (linkage), can foil belt tension feedback to winding machine or grid control, brake create tension.The tension is stable and reliable.

5)using compressed air to generate tension, the whole machine hydraulic system, the whole machine without vulnerability consumable, less point of failure, reduce maintenance cost, less mechanical adjustment point, improve production efficiency, low noise, no pollution of hydraulic mechanical friction, environmental protection.

Finished coils

If you want to know more,

please Send Inquiry now!

If you have any difficult problems in production,

please Chat with us Now!

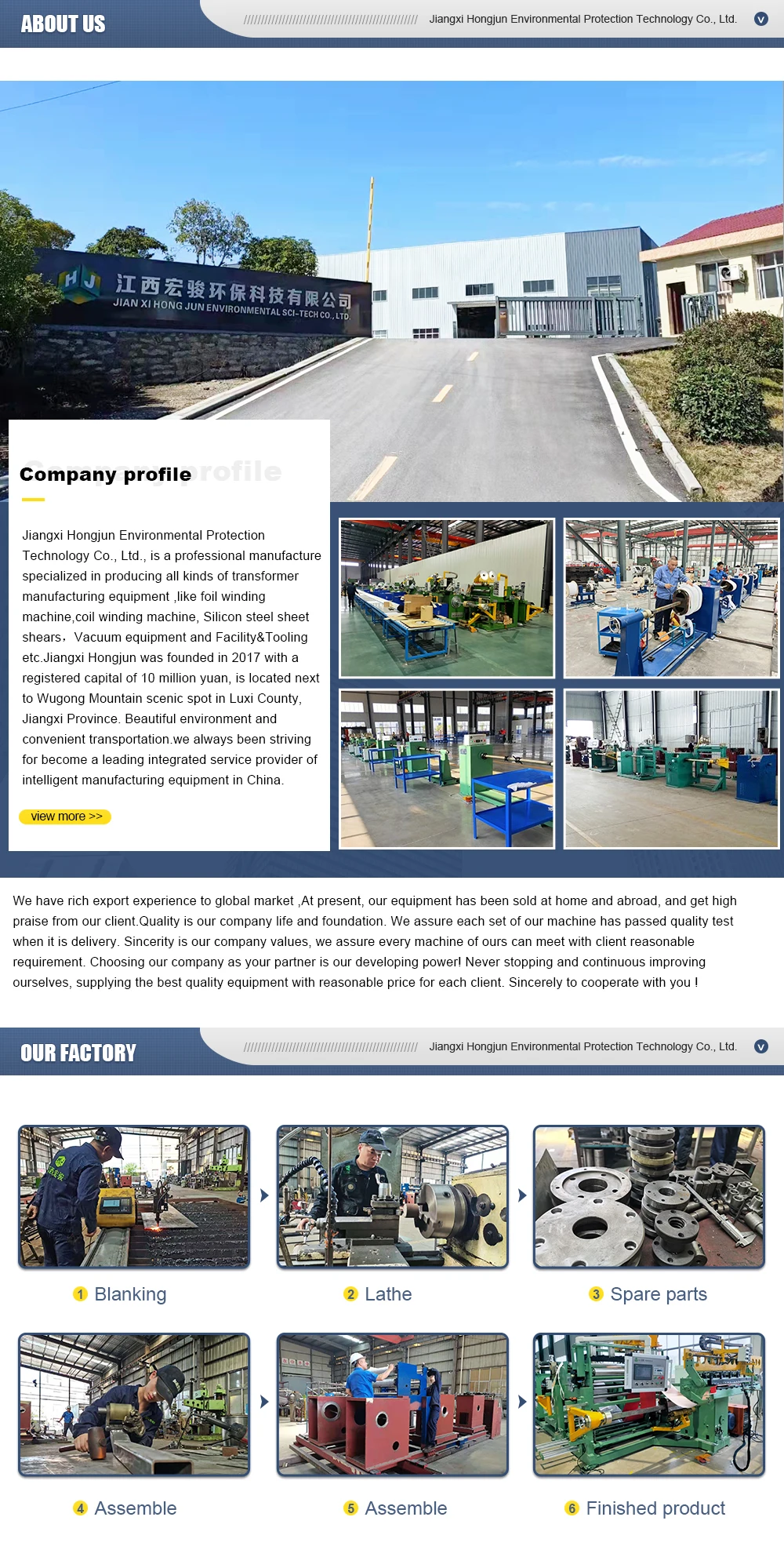

About Us

Exhibition And Customers

Switzerland ABB, Japan TAMURA, China TBEA, India SSE and ESE are our customers.

Certifications

Pre-sale service

The expert design team can help you solve the transformer winding machine and consulting work required for the production line, helping you save investment and reduce energy consumption.

Process services

For the task you entrusted to Hongjun, our professional management team will do every detail according to the national high standard of quality.

After-sales service

Hongjun's after-sales team is skilled and experienced. We promise to replace or repair the damaged part free of charge during the warranty period.

The expert design team can help you solve the transformer winding machine and consulting work required for the production line, helping you save investment and reduce energy consumption.

Process services

For the task you entrusted to Hongjun, our professional management team will do every detail according to the national high standard of quality.

After-sales service

Hongjun's after-sales team is skilled and experienced. We promise to replace or repair the damaged part free of charge during the warranty period.

If you want to know more,

please Send Inquiry now!

If you have any difficult problems in production,

please Chat with us Now!

Packaging & Shipping

Good protection for machines

The finished machine is immediately subjected to anti-rust treatment, and use plastic packaging for further protection, delivery with thick wood frame protection, and other diversified packaging conditions to ensure that products are not affected during long sea shipping.

FAQ

Q:How do I choose the suitable machine?

A:You can tell me your specifications and we can choose the best model for you. We also have some regular models for you to choose from. And you can also provide drawings, dimensions, photos of your products, then we can design a suitable machine for you according to your requirements.

Q:Whether the machine price can be more discount?

A:Hongjun factory always provides high-quality machines, as we all know, overseas market is more important and difficult than domestic market due to after-sale communication time and cost, so our machines always have enough quality standard to ensure that the machine can be more than the real warranty period. In this way, we will save a lot and think ahead for our customers. In fact, Hongjun also considers our price level, we will definitely provide quality = price and price = quality, matching price, customers can accept, our machines are durable. We welcome you to negotiate with us and get good satisfaction.

Q:How is the quality of your machines?

A:All machines should be strictly inspected before shipment. We can do a direct video inspection with you to ensure good functionality and appearance. And our machines have a 12 months long warranty after you received the machines, for abnormal failures caused by machine design or manufacturing defects, free repairs and accessories will be provided. More than 5 documented machine repairs caused by machine design or manufacturing defects in a year, we will extend the warranty for 6 months.

Q:How is the productivity of your machines?

A:We have a team of professional engineers who are always working to simplify the operation of the machine. We can provide complete technical solutions according to the performance, process and requirements of your products. We have customers in China and all over the world. After receiving feedback from our customers, we keep simplifying our machines to achieve higher and higher productivity.

Q:What if parts are damaged or missing after the machines arrive?

A:Please rest assured, we will test the machine before shipping, We can do a direct video inspection with you to ensure good functionality and appearance. And our machines have a 12 months long warranty after you received the machines. Any non-human damaged parts can be replaced free of charge. After receiving your feedback, we will send you new parts within 24 hours. If we do not respond to your feedback, Alibaba will coordinate intervention to ensure your rights.

Q:What should I do if the machine fails after the warranty period?

A:Our machines have a 12 months long warranty after you received the machines, more than 5 documented machine repairs caused by machine design or manufacturing defects in a year, we will extend the warranty for 6 months. Beyond the warranty period, we can provide paid maintenance services. You can also contact us if you need replacement parts. If you have operational problems, you can consult us at any time, and we will help for free.

If you want to know more,

please Send Inquiry now!

If you have any difficult problems in production,

please Chat with us Now!

VIEW MORE

YOU MAY LIKE