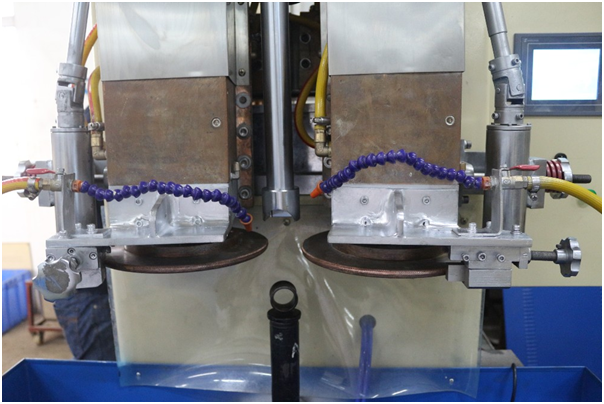

Automobile shock absorber repair machine, resistance seam welding machine

- $2000.00 /set

- 1 set

- Guangdong Hwashi Technology Inc.

- Guangdong, China

- Ms Kary Hou

PRODUCT DETAIL

| Cooling water: | 6 l/min | Packaging Preview: | |

| input power: | 150KVA | Electrode distance: | 145-165mm |

| Main selling point: | automatic | Input voltage: | 220V |

| Welding method: | arc welding | SCR: | SEMIKRON, IXYS, IR |

| Output current: | 8000A | Welding Diameter: | 50-800mm |

| usage: | Welding motorcycle shock absorbers | Weight (kg): | 600kg |

| Molding time: | 1 minute | Showroom location: | not any |

| Warranty: | 1 year | Health status: | new |

| After-sales service provided: | Engineers can repair machinery overseas | Core Components Warranty: | 1 year |

| Supply capacity: | 50 sets per month | Pressurized: | 200kg |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Mechanical test report: | if |

| Video external inspection: | if | Name: | Automobile shock absorber repair machine, resistance seam welding machine |

| Packaging Details: | Seaworthy wooden packaging | Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump |

| port: | Shenzhen | aspect: | 1750*800*1500mm |

| Welding area: | Welding of shock absorbers/motor shock absorbers | Marketing Type: | Hot Products of 2019 |

| Voltage: | 380/220V | brand: | Fahrenheit |

| Applicable industries: | Building material stores, mechanical repair shops, manufacturing plants, construction works | place of origin; place of origin: | Guangdong, China |

Our machines have been widely used in various industries, such as kitchenware,

Automobile manufacturing, motorcycle manufacturing, glasses, hardware, household appliances, low-

Voltage equipment, elevators, compressors, etc.

Automobile manufacturing, motorcycle manufacturing, glasses, hardware, household appliances, low-

Voltage equipment, elevators, compressors, etc.

Product Description

Detailed description

• 1. Automobile shock absorber repairing machine, resistance seam welding machine • 2. Use roller electrodes instead of cylindrical electrodes for spot welding, when the welding workpiece moves between the roller plates, the seal welding will produce weld nuggets, which overlap each other, So as to achieve the welding effect. • 3. Generally, AC pulse current or amplitude modulated current is used, and three (single) phase rectification, intermediate frequency and high frequency DC can also be used. Generally, the welding thickness is within 3mm of the veneer. • 4. The seam welding seam consists of welding points. According to the difference of the fusion core, it can be divided into rolling spot welding and airtight seam welding. The formation process of solder joints is divided into three stages: pressure, heating and melting and cooling crystallization like spot welding. • 5. But this welding method is very different from spot welding, because the unavoidable current shunting makes the current field and thermal field in the welding zone different. In addition, the rolling plate used for transferring pressure and energized heating continuously rolls and changes the welding position, resulting in the characteristics of the current field and thermal field distribution and the crystallization of the fusion zone related to the speed of the position change.

feature

1. Adopt intelligent microcomputer single chip controller to realize pure digital setting. Online computer programming, LED digital display, stable performance, easy to modify the program online. 2. Adopt intelligent microcomputer to control the welding system. When the voltage fluctuates, the welding current is automatically compensated to ensure the stability of the welding. 3. Digital circuit control is adopted; components from world famous factories are selected to ensure long-term stable operation of the equipment. 4. Using West German SEMIKRON, American IXYS, IR thyristor. High precision, long service life, and high stability control of current amplitude. 5. The drive shaft adopts the latest mercury conduction technology from abroad. State-of-the-art technology, good transmission and electrical conductivity. 6. The welding roller is made of Japanese alloy copper material. High rigidity and good electrical conductivity. 7. The transformer adopts Japanese high-purity silicon steel sheet, which has good magnetic conductivity and good electrical conductivity. Low power consumption. Stronger and more stable power. 8. The connection between the welding mold and the whole machine adopts mosaic connection. Easy to assemble and disassemble. 9. There are AC pulse, secondary rectification and capacitor discharge welding power sources to choose from.

Applicable fields

Automobile, motorcycle shock absorbers, thermostat probes, battery nickel strips, oil heaters, power capacitors, sieve frying baskets, pump manufacturing, canning manufacturing, barrel manufacturing, etc.

Specification

Model | Welding wheel method | Input voltage | Output Power | Output current |

WL-FSH-16K | horizontal | 220/ 380V | 16KW | 10000A |

WL-FSL-25K | round | 220/ 380V | 25kW | 12000A |

WL-FSH-25K | horizontal | 220/ 380V | 25kW | 12000A |

WL-FSH-35K | horizontal | 380V | 35kW | 16000A |

WL-FSZ-50K | vertical | 380V | 50kW | 19500 a |

WL-FSZ-75K | vertical | 380V | 75kW | 24000A |

WL-FST-50K | special machine structure | 380V | 50kW | 19500 a |

WL-FST-150K | special machine structure | 380V | 150kW | 40000A |

WL-FST-200K | special machine structure | 380V | 200kW | 50000A |

WL-FS-100K | vertical | 380V | 100kW | 30000A |

VIEW MORE

YOU MAY LIKE